metal bushing benefit

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

metal bushing benefit

about the company

How to make a cost justification for self-lubricating bearings

How do we communicate to management that superior self-lubrication equals good business? Isn’t that a big question? The most frequently asked question in lubricated bearing applications is “How important is self-lubricating bearings?”

Product Quality Index

Energy Generation

Bushing advantages: Self-lubricating and provide quieter operation than most bearings.

Metal bearing technological innovation to promote enterprise development. Choose from our selection of metal bushings in a wide range of styles and sizes. In stock and ready to ship.

Metal Bushing Benefit

With the increasing requirements for specifications of high-performance equipment and systems in industrial applications, metal bushing bearings need to operate under extreme conditions and have a variety of characteristics.In order to meet the ever-changing needs of customers, metal bushing bearing manufacturers are using different materials to make different metal bushing bearing parts, of which metal is one of the most important materials.

High-Performance Metal Bushing Bearings & Wear Parts For Your Applications

Modern bearing technology in metal: We have the right solution for you.

Specialist in developing high performance metal bushing, engineering lubricating bronze bearings, high temperature resistant oilless bearing materials, bronze alloy metals & protection solutions. Metal are processed in a series of ways to maximize their performance and longevity. Using improved metal bushings products can make the product run more efficiently, quietly and smoothly. In addition, maintenance costs are lower compared to conventional steel bearings.Can also be used for insulation, lubrication free occasions, easy processing, high efficiency. For more information, to order or speak to a member of our product team.

Ready to growth your business?

Metal bearings and Maintenance-free sliding bearings, An integral manufacturer from sheet sintering to finished metal bushings products. Constantly study the latest self-lubricating bearings technology & materials and research & development of the new products. Feature a hardened steel backing with an inner lining of PTFE or POM. Cylindrical, flanged and thrust bushings forms are available.

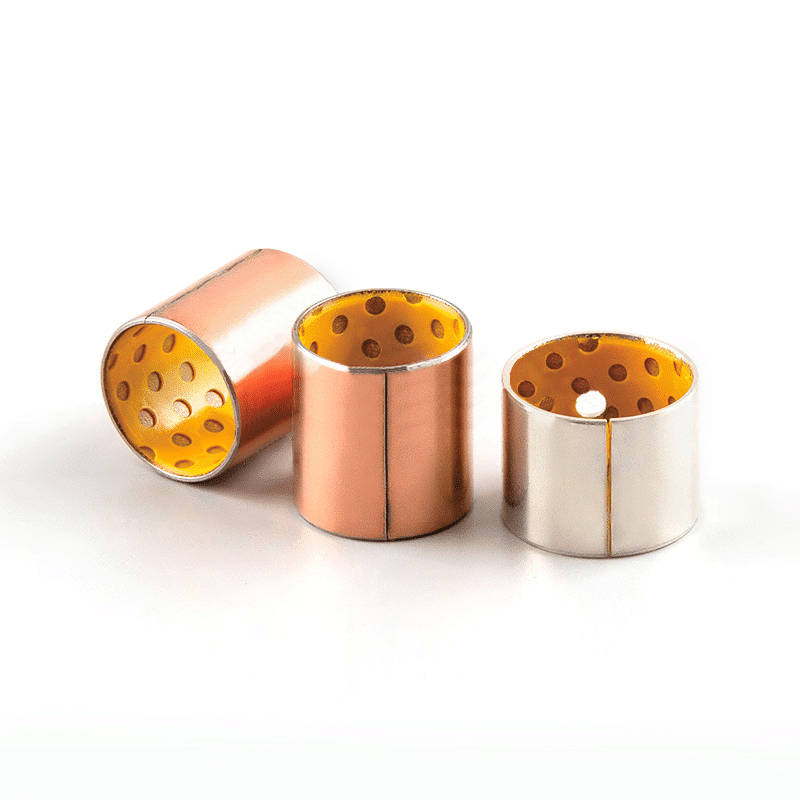

Metal Bushings Self-lubricating Bearings

Metal bushings, also known as wrapped bronze bearings, are a type of bearing that is commonly used in various applications, including machinery, automobiles, and construction equipment.

Wrapped bronze bearings consist of a metal shell made of steel, bronze, or other materials, which is lined with a layer of porous bronze. The pores in the bronze layer are then filled with a lubricating oil or grease to reduce friction and wear.

The metal shell provides the necessary strength and durability, while the bronze layer with lubricant provides the necessary low-friction surface for the rotating shaft to slide against. Wrapped bronze bearings are generally suitable for applications with low to medium speeds and loads. Dry sliding bearing meal material. Advantages of stainless steel self-lubricating bearings 1. Excellent corrosion resistance: stainless steel bearings are very good, with excellent corrosion resistance, it is not easy to rust. A self-lubricating bearing is a steel, bearing is a component that holds and reduces the coefficient of friction of the load during the rotation of machinery. In contemporary machinery, bearings play a pivotal role in reducing the coefficient of friction during power transmission and keeping the shaft center position fixed. The materials used to manufacture self-lubricating bearings are carbon steel, copper, and bimetal.

Metal Bushings – Wrapped Bronze Bearing

wrapped bronze bearings are a reliable and cost-effective solution for many types of machinery and equipment, providing low friction, long life, and minimal maintenance requirements.

Lubricating Bearing. Metal materials are more common materials in bearings, mainly including bearing alloys, copper alloys, aluminum-based alloys, brass alloys and so on. Among them, bearing alloys, also known as shingle alloys, have good wear resistance and wear reduction properties; Some advantages of wrapped bronze bearings include their relatively low cost, ability to withstand high temperatures and corrosive environments, and resistance to shock and vibration. However, they may not be suitable for high-speed applications, as the lubrication layer may not be sufficient to prevent overheating and wear.

Cost-effective metallic bushing

cost-effective metallic bushings offer a reliable and affordable solution for a range of industrial and commercial applications, providing long-lasting performance and durability at a reasonable cost.

A cost-effective metallic bushing is a type of bearing that provides reliable performance at a reasonable cost. These bushings are typically made of materials such as steel, bronze, or brass and are designed to provide low-friction, long-lasting operation for a range of industrial and commercial applications.

Custom Design, Find The Right Self-lubricating Supplier For Your Metal Bearing Needs, “Reliable!” “The biggest advantage of metal bearings is easy processing, low cost, cheaper; good impact resistance. Metal self-lubricating graphite bearings have good wear resistance. Not used to self-lubricating bearings have the advantage of corrosion resistance, especially suitable for use in the corrosive working environments;

We manufacturing self-lubricating metal bushing tailored to your individual needs.

Self-Lubricated Metal Bushings: A Guide to Maintenance-Free Bearings

A metal bushing is an essential component in many mechanical devices. It helps reduce friction and wear between moving parts, providing smooth and reliable operation. However, traditional metal bushings require regular lubrication, which can be time-consuming and messy. In contrast, self-lubricated metal bushings offer a convenient solution to this problem by eliminating the need for regular lubrication.

What are Self-Lubricated Metal Bushings?

Self-lubricated metal bushings are bearings that contain a built-in lubricant that is continuously released as the bushing moves. This type of bushing is designed to provide long-lasting, maintenance-free performance. The self-lubricating material is typically made of a combination of graphite, PTFE (polytetrafluoroethylene), and other materials that are blended together to create a composite that has low friction and high wear resistance.

Benefits of Self-Lubricated Metal Bushings

Self-lubricated metal bushings provide several benefits over traditional metal bushings. The main advantage is that they eliminate the need for regular lubrication, saving time and reducing maintenance costs. Additionally, self-lubricated bushings are less likely to leak or spill lubricant, making them a clean and efficient solution.

Another advantage of self-lubricated metal bushings is that they can operate in environments where traditional bushings may not be able to function. For example, they can be used in applications that are exposed to extreme temperatures, high humidity, and other harsh conditions. Self-lubricated bushings are also resistant to corrosive substances, making them a durable and reliable option for a wide range of applications.

Applications of Self-Lubricated Metal Bushings

Self-lubricated metal bushings are widely used in a variety of industrial and consumer applications, including:

Automotive and transportation equipment: Self-lubricated bushings are commonly used in automotive and transportation equipment, such as cars, trucks, and trains. They provide reliable performance and require minimal maintenance, making them a popular choice for these applications.

Industrial machinery: Self-lubricated bushings are often used in industrial machinery, such as conveyors, robots, and other equipment. They provide smooth and efficient operation, reducing downtime and maintenance costs.

Consumer products: Self-lubricated bushings are also used in a variety of consumer products, such as appliances, power tools, and other household items. They offer long-lasting performance and convenience, making them a popular choice for these applications.

Conclusion

Self-lubricated metal bushings offer a convenient solution to the maintenance and lubrication requirements of traditional metal bushings. They provide long-lasting, maintenance-free performance and can operate in harsh environments, making them a reliable and cost-effective option for a wide range of applications. If you’re in need of a bearing solution that is easy to install and maintain, consider using a self-lubricated metal bushing in your next project.

Embedded Solid Lubricant Bronze Metal Bushing Bearings: The Future of Friction Reduction

Maintenance-Free Operation with Embedded Solid Lubricant, Maintenance-free bearing material for heavy duty applications. Available with the graphite plugs options Suitable for temperatures up to 250°C/480°F! Bushing bearings are critical components in various industrial and consumer products, as they help reduce friction between moving parts, providing smooth and efficient operation. However, traditional bushings require regular lubrication, which can be time-consuming and messy. The solution to this problem lies in embedded solid lubricant bronze metal bushing bearings.

What are Embedded Solid Lubricant Bronze Metal Bushing Bearings?

Embedded solid lubricant bronze metal bushing bearings are bearings that have a built-in lubricant that is made of a low-friction material. This material is integrated into the bushing itself, so it continuously releases as the bushing moves. This type of bushing is designed to provide long-lasting, maintenance-free performance, making it a convenient solution for applications where regular lubrication is not feasible.

Benefits of Embedded Solid Lubricant Bronze Metal Bushing Bearings

Embedded solid lubricant bronze metal bushing bearings offer several advantages over traditional bushings. The main benefit is that they eliminate the need for regular lubrication, saving time and reducing maintenance costs. Additionally, the built-in lubricant is protected within the bushing, so it is less likely to leak or spill, making it a clean and efficient solution.

Another advantage of embedded solid lubricant bronze metal bushing bearings is that they can operate in harsh environments, such as high temperatures and high humidity, where traditional bushings may not be able to function. This type of bushing is also resistant to corrosive substances, making it a durable and reliable option for a wide range of applications.

Applications of Embedded Solid Lubricant Bronze Metal Bushing Bearings

Embedded solid lubricant bronze metal bushing bearings are widely used in various industrial and consumer applications, including:

Automotive and transportation equipment: Embedded solid lubricant bronze metal bushing bearings are commonly used in automotive and transportation equipment, such as cars, trucks, and trains. They provide reliable performance and require minimal maintenance, making them a popular choice for these applications.

Industrial machinery: Embedded solid lubricant bronze metal bushing bearings are often used in industrial machinery, such as conveyors, robots, and other equipment. They provide smooth and efficient operation, reducing downtime and maintenance costs.

Consumer products: Embedded solid lubricant bronze metal bushing bearings are also used in a variety of consumer products, such as appliances, power tools, and other household items. They offer long-lasting performance and convenience, making them a popular choice for these applications.

Conclusion

Embedded solid lubricant bronze metal bushing bearings represent the future of friction reduction in various industrial and consumer products. They provide long-lasting, maintenance-free performance and can operate in harsh environments, making them a reliable and cost-effective option for a wide range of applications. If you’re in need of a bearing solution that is easy to install and maintain, consider using embedded solid lubricant bronze metal bushing bearings in your next project.

The Self-lubricating material, bearing & metal bushing provider for industrial progress;

Our self-lubricating metal bearings products are widely used in more than 30 fields such as automobile industry, metallurgy, engineering machinery, construction machinery, plastic machinery, machine tool industry, water conservancy and hydropower. There are many factors to consider when designing a bearing pivot, including service life, machine use, load capacity and environment, to name just a few. However, the most critical factor is understanding how corrosion (the number one cause of pivot shaft failure) affects the bearing housing, shaft and bushing. Understanding this will help you achieve a successful, maintenance-free pivot design.

Corrosion Protection: When using metal bushings, you must use grease to keep the bearing pivot free to move, this is also done to protect the shaft and housing from corrosion. To design a maintenance free self-lubricating bearing, we also have a more corrosion resistant stainless steel metal composite self-lubricating bushing with better corrosion resistance and high load capacity from corrosion. Finally, consider using a dry-running metal self-lubricating dry bushing instead of a metal bushing. Self-lubricating bushings do not require additional external lubrication, and metal split bearing bushings are easier to install because they do not require as precise housing tolerances. For more information on designing maintenance-free self-lubricating bearings, please contact us.

Metal Bearing Bushing Bronze Alloy Selection

Delivered Self-lubricating Bearing for Complete Engineering Challenge! Metal Bearing Bushing Bronze Alloy Selection: A Guide to Choosing the Right Material.

Metal bearing bushings are essential components in a wide range of applications, providing support and reducing friction between moving parts. One of the key factors in choosing the right metal bearing bushing is selecting the right bronze alloy. This article provides an overview of the most common bronze alloys used in metal bearing bushings and the factors that you should consider when making a selection.

Common Bronze Alloys Used in Metal Bearing Bushings

Lead Bronze (C93200): Lead bronze is a soft and malleable alloy that is often used in metal bearing bushings. It provides excellent wear resistance and low friction, making it a popular choice for applications that require high load capacity and low speed operation.

Aluminum Bronze (C95400): Aluminum bronze is a strong and corrosion-resistant alloy that is often used in metal bearing bushings. It provides excellent wear resistance, high hardness, and low friction, making it a popular choice for applications that require high performance and durability.

Manganese Bronze (C86300): Manganese bronze is a high-strength alloy that is often used in metal bearing bushings. It provides excellent wear resistance, high hardness, and low friction, making it a popular choice for applications that require high load capacity and high speed operation.

Tin Bronze (C93700): Tin bronze is a soft and malleable alloy that is often used in metal bearing bushings. It provides excellent wear resistance, low friction, and good corrosion resistance, making it a popular choice for applications that require high performance and durability.

Factors to Consider When Selecting a Bronze Alloy for Metal Bearing Bushings

Operating conditions: The operating conditions of your application should be considered when selecting a bronze alloy for metal bearing bushings. Factors such as temperature, humidity, and exposure to corrosive substances can affect the performance of the bushing and should be taken into account when making a selection.

Load capacity: The load capacity of your application should be considered when selecting a bronze alloy for metal bearing bushings. Factors such as the size of the moving parts and the speed of operation can affect the load capacity of the bushing and should be taken into account when making a selection.

Friction: Friction is an important factor to consider when selecting a bronze alloy for metal bearing bushings. Factors such as the surface finish of the moving parts and the speed of operation can affect the friction of the bushing and should be taken into account when making a selection.

Cost: The cost of the bronze alloy should be considered when selecting a bronze alloy for metal bearing bushings. Some alloys are more expensive than others, so it is important to choose a material that provides the performance you need at a cost that is within your budget.

Conclusion

Choosing the right bronze alloy for metal bearing bushings is important for ensuring that your application performs as expected. The factors outlined above should be considered when making a selection, so that you can choose a material that provides the performance and durability you need at a cost that is within your budget. Whether you’re designing a new product or upgrading an existing one, selecting the right bronze alloy is an important step in ensuring the success of your project.

Standard and correct bearing material design, select the metal bearing products for customers efficiently and correctly.

Sliding bearings, also known as bushings, journal bearings or plain bearings, are the simplest bearing design. Metal-polymer self-lubricating PTFE bushing bearing material :The smallest friction coefficient, and when the load increases, the friction coefficient decreases accordingly, often add glass fiber, graphite, bronze powder, etc., to improve the performance indicators, the working temperature is relatively high plain metal bushing bearing for your application. Wrapped composite sliding bearing with PTFE fabric overlay, maintenance-free … Cylindrical bushing + inner diameter / length.Wrapped composite sliding bearing with PTFE fabric overlay, maintenance-free … Cylindrical bushing + inner diameter / length.

High Performance, Low Wear Composite Metal Bushing Solutions

Pre-finished metal sliding bearings. Spherical plain bearings POM metal bushing material: POM has excellent sliding and wear resistance, high heat resistance and chemical stability. Features: High mechanical strength, high rigidity, high hardness; Excellent elasticity; Good creep resistance; Even at low temperature, high impact strength; Very good dimensional stability; Good sliding performance and wear resistance; Excellent mechanical properties. Discover our high-performance, low-wear composite metal bushing solutions. Our advanced materials and manufacturing techniques ensure long-lasting performance and durability. Contact us to find out how we can meet your specific application needs.

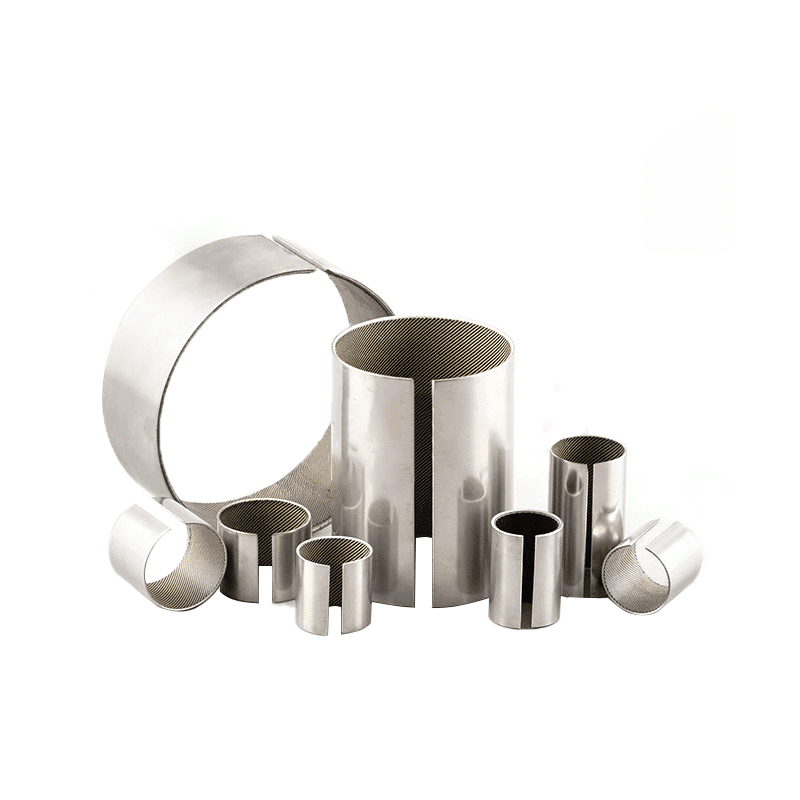

Custom Metal Bushing and Bearing Manufacturing

Manufacturer of self-lubricating metal bushing materials and bronze bearing components with many years of experience. The diversified product range includes bronze wear parts and oilless bearings, engineering bushing, high temperature resistant stainless steel backed bushing materials, bimetal and steel bearings, and dry bearing bushing custom size solutions. Currently used metal bushing bearings can be generally divided into metal rolling bearings and metal sliding bearings; The working principle of metal rolling bearings and metal sliding bearings can be distinguished by their names. The friction of metal rolling bearings when they work is rolling friction, while that of metal sliding bearings when they work is sliding friction. Choose Your Metal Bearings,Polymer Coating Material

Your specialist for plain bearings and metal bushings components.

Find your metal bushing — Change the bearing, Plain bearing design, modification, manufacturing and quality. We specialize in manufacturing plain bearings and metal bushing components. Trust us to provide you with high-quality solutions for your industrial needs. Contact us today to learn more.

Metal bushings products are more and more widely used because of their excellent performance, and metal bushing bearings are being welcomed by more and more users. Because metal bushing material have excellent self-lubrication, wear resistance, low friction and special anti-bite characteristics, even in the case of poor lubrication conditions can also work normally, so it is very ideal as bearing materials.

Our Self-lubricating Metal Bushing Bearing Series are made of metal bearing materials and processed by injection molding, providing excellent wear resistance and low friction under both dry and lubricated conditions.In addition to high impact load resistance and noise reduction, our metal bushings provide environmentally friendly, grease-free operation that minimizes maintenance requirements.

Custom Engineered Self-lubricating Metal Bushings Bearing Solutions

Self-lubricating metal bushing benefits

- No lubrication: dry friction operation, no lubrication required

- Weight reduction: Lightweight components reduce unnecessary weight

- Wear and corrosion resistance: Wear and corrosion resistance, ideal for harsh, dusty and humid environments

- Noise reduction: Damping and non – stick – slip characteristics reduce noise problems

- Flexible design: Injection molding offers flexible design options

- Dimensional stability: excellent dimensional stability and low friction system

Custom bearing bushings for harsh and extreme environments

Custom bearing bushings designed for harsh and extreme environments are an essential component in many industrial applications. These bushings are specifically engineered to withstand extreme temperatures, high pressure, abrasive materials, and corrosive environments, making them ideal for use in industries such as mining, oil and gas, marine, and aerospace.

Custom bearing bushings designed for harsh environments typically incorporate specialized materials such as stainless steel, bronze, or ceramic, which offer exceptional strength and durability under extreme conditions. In addition, they may incorporate unique features such as self-lubricating properties, which help to reduce friction and wear over time.

When designing custom bearing bushings for harsh environments, it is important to consider a range of factors such as load capacity, speed, temperature range, and chemical compatibility. Working closely with a reputable custom bushing manufacturer can help ensure that the bushings are specifically tailored to meet your unique requirements and perform reliably over the long term.

Custom bearing bushings for harsh and extreme environments are an essential component in many critical industrial applications, and investing in high-quality, custom-designed bushings can help improve equipment performance, reduce downtime, and extend the lifespan of your machinery.

Bearings and Bushings are Made from what Metal?

Bearings and bushings can be made from a variety of materials, depending on the specific application and performance requirements. Some common metals used for bearings and bushings include:

- Steel: Steel is a popular material for bearings and bushings due to its high strength, durability, and wear resistance. It is commonly used in applications with heavy loads and high speeds.

- Bronze: Bronze is another popular material for bearings and bushings, especially in applications that require high levels of corrosion resistance. It also offers good wear resistance and low friction.

- Brass: Brass is a softer metal than steel or bronze, but it still offers good wear resistance and low friction. It is often used in applications where noise and vibration are a concern.

In addition to these metals, other materials such as plastics and composites may also be used for bearings and bushings in certain applications. The choice of material will depend on factors such as load capacity, speed, temperature range, and chemical compatibility, as well as any specific performance requirements of the application.

There are so many options for bearings and bushings on the market today, including metal, polymer, and composite.

Metal bushing benefits in variety applications

PTFE lined bearing

Types of Composite Bushings and Bearings

Exactly what is meant by the term “composite bushing” can vary according to manufacturer. For example, there are composite bushing designs that combine a steel backing with a sintered bronze layer covered with a polymer lining such as PTFE. There is also a more classic approach to composite bushings that combines a polymer resin with glass fibers, often filament wound, and a PTFE lining to reduce friction and provide lubrication.

Composite Options for Bushings and Bearings

When it comes time to select a bushing or bearing for a particularly sensitive application, it might be wise to add composites to your list of potential bearing materials. Composite bearings may be primarily metal with a low-friction polymer lining, or they may be filament wound fiber reinforced materials with a polymer matrix. Regardless of which type of composite bearing is under consideration, remember that they can offer added benefits such as improved strength, stiffness, wear properties, and reduced friction while possibly eliminating the need for lubricants.

Innovations in custom bushing design and manufacturing

Custom bushing design and manufacturing have undergone significant innovations in recent years, thanks to advancements in technology and materials. Here are some of the latest innovations in this field:

- 3D Printing: 3D printing has revolutionized the manufacturing industry by enabling the production of complex and customized parts quickly and cost-effectively. With 3D printing, custom bushings can be designed and produced to precise specifications, reducing lead times and minimizing waste.

- Advanced Materials: New materials, such as composites, polymers, and hybrid materials, are now being used to manufacture custom bushings. These materials offer improved performance, durability, and weight reduction, making them ideal for use in harsh environments and high-stress applications.

- Innovative Design: Innovative design techniques, such as topology optimization and finite element analysis, are being used to create custom bushings that are optimized for specific applications. These design methods can help to improve the overall performance of the bushings, increase their lifespan, and reduce maintenance requirements.

- Automation: Automation technologies, such as robotics and machine learning, are being used to improve the efficiency and accuracy of custom bushing manufacturing. These technologies can reduce lead times, improve product quality, and increase production capacity.

Overall, these innovations are transforming the custom bushing design and manufacturing industry, enabling the production of high-performance, customized solutions that meet the specific needs of different applications and industries.

Benefits of Composite Bearings

Composite bearings are an innovative solution for various industrial applications. By combining the best properties of multiple materials, these bearings offer several benefits that traditional bearings cannot match.

- Strength, Stiffness, and Low Friction

One of the primary benefits of composite bearings is their exceptional strength and stiffness properties. By combining a steel backing with a polymer layer such as PTFE or POM, the bearings can withstand heavy loads and harsh operating conditions while maintaining low friction. The polymer layer provides excellent tribological properties, reducing wear and tear, and enhancing the durability of the bearing.

Moreover, composite bearings offer excellent corrosion resistance, making them suitable for use in corrosive environments. The polymer layer acts as a barrier, protecting the metallic layer from unwanted chemical interactions and corrosion.

- Dry-Running Capability

Many composite bearings are designed to operate without grease or lubricant, making them ideal for applications that are sensitive to contamination or where grease could pose a problem. Composite bearings can provide extreme low friction, almost eliminate issues with stick-slip, and reduce break-away torque requirements. Dry-running capability also results in energy savings and reduced maintenance costs, making composite bearings a more economical choice for certain applications.

- Dimensional Stability

Composite bearings can address the issue of dimensional stability quite well. Some polymers are susceptible to dimensional changes through the absorption of water or reactions to temperature variations. Composite bearings can significantly reduce these problems by using materials that are less susceptible to dimensional changes. This enhances the reliability and lifespan of the bearing and ensures that it performs consistently over time.

In conclusion, composite bearings offer exceptional strength, stiffness, low friction, dry-running capability, and dimensional stability. They are an ideal solution for applications that require high performance, durability, and reliability. By working with a reputable manufacturer, you can ensure that your composite bearings are designed to meet your specific requirements and performance needs.

Metal and Bimetal Bushings Benefits

Metal and bimetal bushings are commonly used in industrial applications due to their durability, strength, and resistance to wear and tear. In this article, we will discuss the top benefits of using metal and bimetal bushings.

- High Load Capacity

Metal bushings, such as those made from bronze or steel, are capable of withstanding high loads and pressures without suffering from deformation or failure. This makes them ideal for use in heavy machinery and equipment where high strength and load capacity are essential.

- Resistance to Wear and Tear

Metal bushings are also highly resistant to wear and tear, making them suitable for use in harsh and abrasive environments. They can withstand the constant friction and movement that occurs during operation without breaking down or requiring frequent replacement. Bimetal bushings, which consist of two layers of different metals, can further enhance wear resistance by combining the strength of one metal with the wear resistance of another.

- Low Coefficient of Friction

Metal bushings often have a low coefficient of friction, meaning that they can operate with minimal lubrication. This not only reduces maintenance and operating costs but also minimizes the risk of contamination or environmental damage.

- Excellent Thermal Conductivity

Metal bushings also offer excellent thermal conductivity, making them suitable for use in high-temperature applications. They can quickly dissipate heat, preventing overheating and potential damage to the machinery.

- Corrosion Resistance

Bimetal bushings, in particular, can offer excellent corrosion resistance, making them ideal for use in marine and other harsh environments. The use of different metals in the bushing’s construction ensures that they can withstand corrosive substances and moisture without breaking down.

Metal and bimetal bushings offer a range of benefits that make them an ideal choice for various industrial applications. They offer high load capacity, resistance to wear and tear, low coefficient of friction, excellent thermal conductivity, and corrosion resistance. By working with a reputable manufacturer, you can ensure that your metal or bimetal bushings are designed to meet your specific requirements and performance needs.

What Are the Benefits of Metal Bearings and Where Can You Get Them?

Bi-Metal bearings are made from metal alloys, which can include tin, lead, zinc, and bismuth. Of course, each metal bearing will contain a different combination of alloys, depending on the desired strength and other requirements. Bimetal bearings are beneficial in that they offer an extended service life under normal operating conditions. When it comes to excess momentary overloads, these bearings also perform well. When there is an alignment or lubrication problem, the metal bearing can compensate with greater ease than other types of bearings.

The metal bushings & bearings are widely used in pump and rolling mill industries, mining, and marine, and our bearings are used in fans, electric motors, turbine generators, and many other machines.

Extensive Experience with Metal Bearings

If you would like to select from a range of the country’s most advanced and reliable metal bearings available, take the time to contact us at www.bronzelube.com. You simply need to give us a call or send us an email to ensure that your needs and requirements are met and to be provided with a detailed quotation. Why wait? Get in touch today.

Reliable Metal Bushing Supplier

Switch from Metal Bushings Bearing – Lubricated Bearing Solutions

Design a Maintenance-Free Metal Bushing and Bearings. Cost-Effective Prices. Highlights: Brochures Available, Offering Cost-Effective Prices. To be considered cost-effective, metallic bushings must balance performance and durability with affordability. This often means using high-quality materials and manufacturing techniques to create bushings that can withstand the rigors of heavy use while remaining affordable for a range of customers and applications.

Some common features of cost-effective metallic bushings include their ability to operate at high speeds and under heavy loads, as well as their resistance to wear, corrosion, and other forms of damage. Additionally, many cost-effective bushings are designed to be easy to install and maintain, minimizing downtime and reducing overall costs.

Custom metal bushing bearing manufacturing

24/7 emergency callout

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.