Self-lubricating bearing industry overview

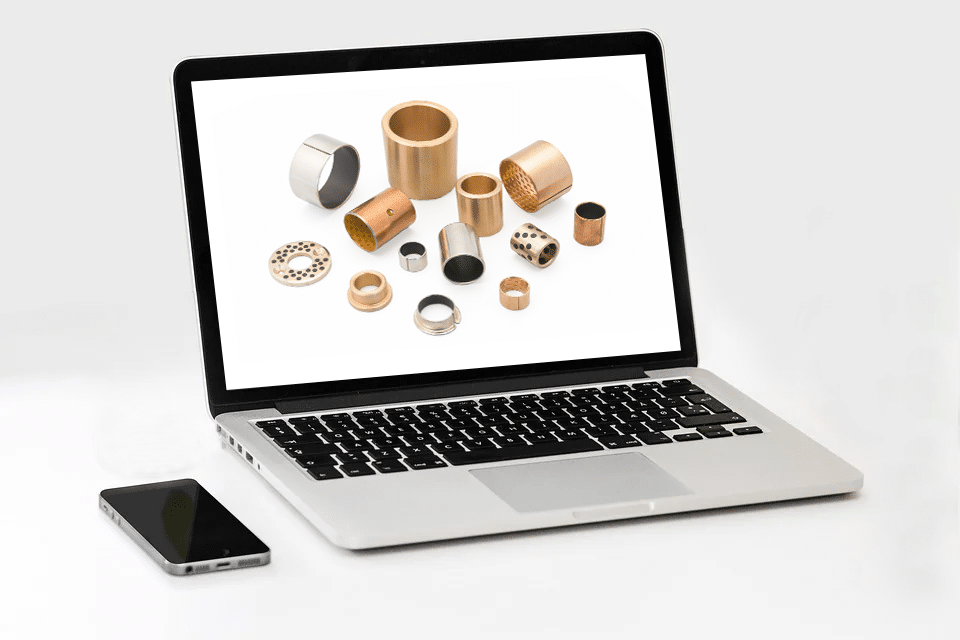

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Self-lubricating bearing industry overview

Product Selection Guide

What Are Self-Lubricating Bearings?Innovation. Commitment. Quality.

Self-lubricating bearings, as the name suggests, provide their own lubrication during operation without requiring the application of grease or oil lubricants. These maintenance-free or greaseless bearings work by having lubricants impregnated within their bearing surfaces!

Self-lubricating products are ideal for a multitude of applications where components are inaccessible as lubrication is unnecessary. These products are offered in different sizes and configurations, giving them the ability to be designed to satisfy customer’s needs.

Types of Self-Lubricating Bearings

Self-Lubricating, Maintenance Free Bearings Bushing

Self-Lubricating Bearing Plain Bearing : Improving productivity and save the cost and time with various kind of shapes and materials, etc.

Types of Self-Lubricating Bearings: There are two main categories of self-lubricating bearings:

Metallic bearings: Made of sintered bronze, copper, aluminum alloys, lead, and sintered iron and copper.

Non-metallic bearings: Include polymer bearings (PTFE), Polyacetal, Polyethylene, resin-based plastics, Polytetrafluoroethylene, woven fibers, and carbon graphite.

Self-lubricating bearings find extensive use in various industries, with the automotive and aerospace sectors being the primary beneficiaries!

Well-chosen industrial products, authentic and quality products

All varieties from standard bearings product to customized bushings products

Self-Lubricating Bearing & Bushing Materials.

Your Partner for Sliding Bearing Technology.

Properly specified, self-lubricating bearings reduce maintenance costs, extend bearing life, and are more environmentally friendly. The self-lubricating bearing industry continues to evolve, driven by technological advancements and increasing demand across various sectors. As industries seek more efficient and low-maintenance solutions, the market for self-lubricating bearings is poised for continued growth.

We offer High performances for plain bearings at the best price. By understanding the principles, applications, and market dynamics of self-lubricating bearings, businesses can make informed decisions about incorporating these innovative components into their operations, potentially leading to improved efficiency and reduced maintenance costs.

Grease-Free Self-lubricating Bearing. Zero Maintenance for Life.

rewrite below With the development trend in the field of self-lubricating bearings, the production process and raw materials of self-lubricating bearings keep pace with The Times, and the types of commodities are gradually rich and colorful. According to the difference of product structure and production and manufacturing raw materials, self-lubricating bearings are divided into three categories: laminated, single-sided and other categories, which are divided into several subcategories.The actual results are shown below:

“Laminated” self-lubricating bearing products are made of two or two kinds of different kinds of rolling bearing raw materials stacked composite, in which the lining raw materials have the effect of self-lubricating bearing, the plate has the effect of supporting point, and other raw materials have the effect of connecting and connecting. The actual wetting effect of the “multilayer” commodity is of high quality, and its bearing capacity is determined by the tensile strength of the surface material.According to the type of sheet material and lining material, it can be divided into metal material sheet and metal material lining layer, metal material sheet and non-metal material lining layer and non-metal material sheet and non-metal material lining layer.

“Single type” self-lubricating bearing products is made from a variety of rolling bearing raw materials, Viiplus authorized dealer of goods with the aid of rolling bearing with self-lubricating bearing raw material in the raw materials such as high purity graphite, molybdenum disulfide, ptfe, lead etc. In order to develop RunHua, according to the type of rolling bearing raw materials, can be divided into metal materials and nonmetal materials. Non-metallic material single-sided self-lubricating bearings include the overall non-metallic material rolling bearings, non-metallic material production rolling bearings, etc. Metal material single-sided rolling bearings include solid – state embedded products and oil – containing products.” Solid embedding type” self-lubricating bearings are produced and processed in advance on the metal material sheet according to a certain ordering method, and then solid lubricants are placed in them; In the whole process of work, because of the effect of friction heat or working temperature, solid lubricant is slightly prominent on the rolling surface, and according to the friction, transfer film is produced on the metal material sheet and layer transfer surface, thus having the effect of reducing wear and abrasion. “Oil content type” self-lubricating bearing is the metal powder according to the powder non-metallurgical processing technology to inhibit the calcination into a porous structure of raw materials, and then fill the porosity with grease; In the whole process of work, due to the effect of friction heat or working temperature, the grease is precipitated from the rolling bearing, and the grease film is produced on the metal material sheet and layer transfer surface, thus having the effect of reducing wear and abrasion.

ChatGPT

As the field of self-lubricating bearings evolves, production processes and raw materials are continuously updated to meet modern demands, leading to a diverse range of products. Self-lubricating bearings are categorized into three main types based on their structure and materials: laminated, single-layer, and other specific types, each with its own subcategories.

Laminated self-lubricating bearings consist of two or more layers of different bearing materials. The inner lining material provides self-lubrication, the outer plate serves as a support, and additional materials are used for connectivity. These multilayer bearings offer excellent lubrication quality and their load capacity depends on the tensile strength of the top layer. Depending on the materials used, these can be further divided into combinations such as metal plate with metal lining, metal plate with non-metal lining, and non-metal plate with non-metal lining.

Single-layer self-lubricating bearings are composed of various bearing materials including high purity graphite, molybdenum disulfide, PTFE, and lead, among others. These bearings are categorized based on the material type into metal and non-metal varieties. Non-metal single-layer bearings include entirely non-metallic bearings and those manufactured from non-metallic materials. Metal single-layer bearings are available as solid embedded products and oil-impregnated products. Solid embedded bearings are made by machining slots into metal plates and inserting solid lubricants. During operation, the solid lubricant forms a transfer film on the metal surface due to friction, reducing wear and tear. Oil-impregnated bearings are created using powder metallurgy to form a porous structure filled with grease, which, when heated by friction, exudes to form a lubricating film, thus reducing wear.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.