How to install oil-free bearings?

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

How to install oil-free bearings?

How to Install Oil-Free Bearings: A Step-By-Step Guide

In many industrial applications, the use of oil-free or self-lubricating bearings is becoming increasingly prevalent. These bearings are designed to operate without the need for added lubrication, reducing maintenance requirements and providing reliable performance in a variety of environments. However, to ensure they function correctly and efficiently, proper installation is key.

Installation Instructions for Oil-Free Bearings:

The Future of Oil-Free Bearings,

The development of oil-free bearings is set to advance in several directions:

High Stiffness Gas-Lubricated Bearings: Emphasizing improved bearing stiffness and capacity, research will focus on creating high stiffness gas-lubricated bearings.

High Precision, High-Performance Gas-Lubricated Bearings: To meet the demands of cutting-edge technology, the direction will be towards high precision and high-performance gas-lubricated bearings.

Reliability and Practicality: A key aspect will be to enhance work reliability and practicality through improved manufacturing processes, resulting in bearings that can be mass-produced with a simple structure and dependable performance.

specializing in Oil-Free Bearings

The research and application of water-lubricated bearings encompass multiple disciplines such as mechanical design, tribology, materials science, surface engineering, fluid mechanics, lubrication, and sealing. The current focus lies in several areas:

Material Research: Developing materials with both self-lubricating properties and a strong affinity for water lubrication.

Tribology Mechanism: Understanding the tribological mechanism underlying water-lubricated bearings based on surface engineering.

Testing and Verification: Utilizing advanced experimental testing means to verify the theoretical concepts, especially considering the complex working conditions of composite bearings.

our Oil-free bearing & slide plate

step-by-step guide to installing oil-free bearings.

Guide to Installing Oil-Free Bearings

Tools Needed:

- Clean Cloth: For cleaning surfaces.

- Grease or Oil (Small Amount): For lubrication during installation.

- Mandrel or Oil Push Machine: For controlled installation.

Common Mistakes to Avoid:

- Not Cleaning Surfaces: Ensure bushing and housing are free from contaminants.

- Over-Lubricating: Only a small amount of lubrication is needed during installation, not after.

- Rushing the Installation: Install slowly and carefully to prevent damage.

Proper Lubrication Post-Installation: Oil-free bearings typically do not require lubrication after installation. Their design is such that they operate efficiently without the need for traditional oil or grease. However, during installation, a minimal amount of grease or oil can be used on the outer surface to ease the process. After installation, no additional lubrication is usually necessary, emphasizing the importance of a clean and precise installation. Always refer to the manufacturer’s manual for specific guidance related to your particular bearing type.

Installation Instructions for Oil-Free Bearings: A Comprehensive Guide

When installing oil-free bearings, there are a few key steps and checks to ensure a smooth installation process. Here’s a comprehensive guide:

Here’s a step-by-step guide to installing oil-free bearings.

Step 1: Preparing for Installation

Before you begin the installation process, make sure you have all the necessary tools and protective equipment at hand. This may include a bearing installer tool, a clean cloth, and safety glasses.

Next, clean the housing and shaft where the bearing will be installed. Any debris, dust, or excess oil can affect the bearing’s performance, so it’s crucial to start with a clean environment.

Step 2: Checking the Components

Before installing the bearing, inspect the bearing, housing, and shaft for any signs of wear, damage, or irregularities. Ensure the bearing is the correct size for the housing and shaft. An improperly sized bearing will not perform effectively and could lead to equipment damage.

Step 3: Positioning the Bearing

Position the bearing on the installation tool so that the force applied during installation is evenly distributed over the bearing. The tool should contact the bearing’s outer ring, not the inner one or the seals. This is to avoid damaging the bearing during installation.

Step 4: Installing the Bearing

Insert the bearing into the housing carefully, applying slow and steady pressure. If the bearing needs to be installed onto a shaft, ensure it is mounted squarely and not at an angle. The bearing should be pushed and not hammered into position.

Use the installation tool to press the bearing into place until it is fully seated within the housing or onto the shaft. Be sure to maintain alignment throughout this process to avoid damaging the bearing or the surrounding components.

Step 5: Confirming Correct Installation

Once the bearing is installed, visually inspect it to ensure it is fully seated and correctly positioned. Rotate it by hand to check for smooth operation. Any roughness or binding could indicate a problem that needs to be addressed before the equipment is put back into operation.

Step 6: Reassembling the Equipment

Once you’ve confirmed that the bearing is correctly installed, you can reassemble any equipment that was removed for the installation. Follow the manufacturer’s guidelines for this process to ensure that everything is put back together correctly.

Conclusion

Properly installing oil-free bearings is vital for ensuring their longevity and optimal performance. By following the correct installation steps and taking the time to prepare and inspect your components, you can significantly reduce the risk of premature bearing failure and potential damage to your equipment. Always remember to follow safety protocols during installation and consult the bearing manufacturer’s guidelines if you’re unsure about any part of the process.

You’ve just provided an extensive and comprehensive description of how to install oil-free bearings, and the various factors to consider when undertaking such a task. Here is the English language version:

Installation Instructions for Oil-Free Bearings: A Comprehensive Guide

When installing oil-free bearings, there are a few key steps and checks to ensure a smooth installation process. Here’s a comprehensive guide:

Step 1: Pre-Installation Checks

Before the installation process begins, inspect the contact surfaces of the shaft and housing for any irregularities such as unevenness, protrusions, or debris such as dust or sand on the bearing shell. Minor inconsistencies should be eliminated using an oilstone or fine sandpaper.

Step 2: Preparing the Components

Apply a small amount of lubricating oil to the shaft surface and the shaft housing to ensure a smooth installation process. When applying force to the bearing, it’s crucial to make sure that it’s exerted vertically, avoiding any potential damage to the bearing from lateral blows.

Step 3: Installation Process

Use a gentle tapping motion with a hammer and sleeve, ensuring that the force isn’t concentrated in the center. Any excessive force can lead to damage. In instances where both the inner and outer rings have a tight fit, use a backing plate to ensure force can be applied to both simultaneously.

Step 4: Alternative Installation Method

In some cases, heating the bearing to increase the inner diameter for easier installation might be necessary. Heat the bearing in clean oil to about 80-90 degrees Celsius, but never exceed 100 degrees as it can lead to a reduction in the hardness of the bearing. After reaching the desired temperature, immediately remove the bearing from the oil and swiftly insert it onto the shaft.

Step 5: Post-Installation Checks

After the installation, ensure that there’s no gap between the shaft shoulder and the end face of the bearing. Use appropriate tools to press the bearing in the direction of the shaft if necessary.

Oil-free bearings, also known as plain bearings, offer excellent wear resistance and friction properties, enhancing performance and reducing maintenance requirements. They are an excellent choice for a variety of applications, from mining equipment to machine equipment production lines.

Remember, always follow the manufacturer’s guidelines for bearing installation and consult with professionals if unsure about any part of the process.

Visit www.bronzelube.com to find an extensive range of oil-free bearings suitable for a variety of applications. Our professional team can help you find the right bearing solution to meet your specific needs.

For a reliable, safe, and high-quality selection of self-lubricating bearings, trust in our expertise. We manufacture bushings to meet your exact specifications and ensure quick turnaround times.

Learn more about our offerings and how our advanced bearing technology can benefit your business today!

Oil-free bearings encompass various categories, including:

- Gas-Lubricated Bearings: These sliding bearings utilize gas as a lubricant, with air being the most commonly used gas lubricant. Other gases like nitrogen, argon, hydrogen, helium, or carbon dioxide can also be employed based on specific needs. The gas-lubricated bearings function similarly to liquid-lubricated bearings, leveraging gas properties such as diffusivity, viscosity, thermal conductivity, adsorption, and compressibility to form a complete gas film. This film effectively supports the load and reduces friction.

- Water-Lubricated Bearings: In response to the oil resource crisis and growing environmental concerns, water-lubricated bearings have gained traction. Water serves as the lubrication and working medium, offering significant advantages over traditional oil-based lubrication. Apart from conserving oil resources, water is non-polluting, readily available, safe, and non-combustible. These bearings alleviate issues related to friction, wear, vibration, noise, and reactive energy consumption, making them an ideal choice for improving mechanical efficiency and protecting the environment.

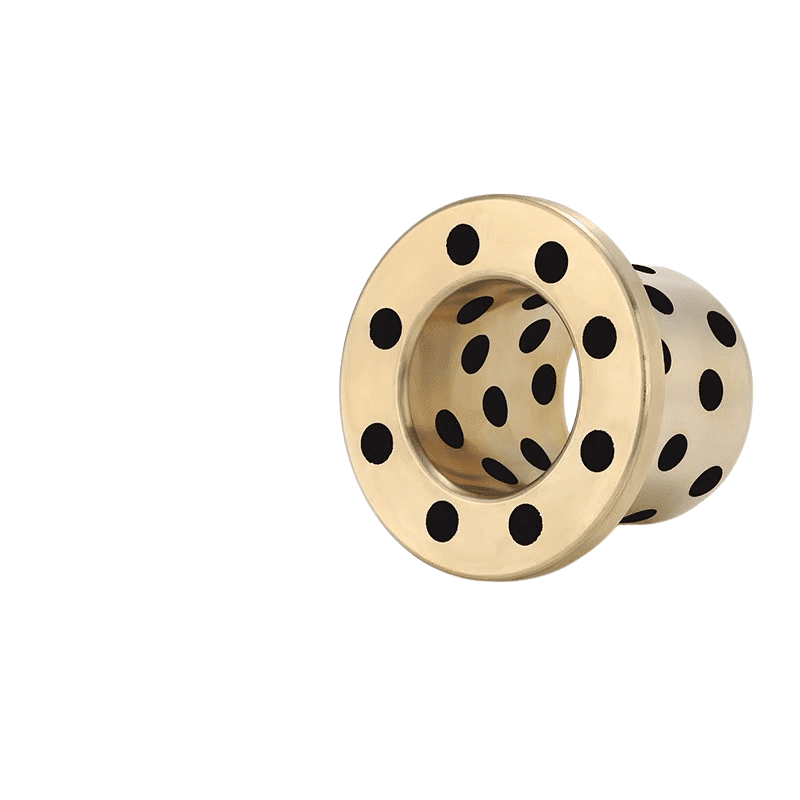

- Metal-Based Solid Inlay Oil-Free Bearings: These bearings feature a metal matrix with inlaid graphite and MoS2 composite solid lubricants. This arrangement breaks through the limitations of conventional oil-film lubrication found in typical bearings. During use, the solid lubricant rubs against the shaft through frictional heat, resulting in excellent oil and powder coexistence lubrication conditions. This not only ensures protection against wear but also confers enduring solid lubrication characteristics.

- Composite Material Lubrication Bearings: Developed to cater to specialized production processes, these bearings excel in harsh working conditions with heavy equipment, high ambient temperatures, and exposure to dust or acidic corrosive gases. The composite material consists of a metal substrate with embedded solid lubricant paste in holes or slots. In the friction process, the metal substrate bears most of the load, while the solid lubricant transfers to the friction surface, forming a well-lubricated, firmly attached, and uniformly covered solid transfer film. This significantly reduces frictional wear and ensures long-term efficient lubrication during extended operation.

- Multi-Layer Composite Oil-Free Bearings: This type of rolled sliding bearing comprises a steel plate substrate, sintered spherical bronze powder in the middle, and a surface layer of polytetrafluoroethylene (PTFE) and lead. It boasts a low friction coefficient, excellent wear resistance, corrosion resistance, and requires no additional lubrication.

Advantages of Oil-Free Lubrication Bearings

- Suitable for Places without Oil Lubrication: Oil-free or low-oil lubrication bearings find application in scenarios where oiling is challenging or not possible. They require minimal or no maintenance.

- Excellent Wear Resistance: These bearings offer low friction coefficients, resulting in prolonged service life.

- Enhanced Load-Bearing Capacity: Under appropriate elasto-plastic conditions, the stress can be distributed over a wider contact surface, thus improving the load-bearing capacity of shaft parts.

- Consistent Friction Coefficients: The static and dynamic friction coefficients are similar, eliminating low-speed creep and ensuring mechanical performance and working accuracy.

- Noise Reduction and Pollution Prevention: Oil-free bearings reduce vibration, lower noise levels, prevent pollution, and improve working conditions.

- Protection against Shaft Wear: During operation, these bearings form a transfer film that shields the grinding shaft, preventing damage.

- Versatile Applications: Oil-free bearings are widely employed in various machinery components, including printing machines, textile machines, automobiles, and agricultural and forestry machinery.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.