The Reasons To Replace PTFE Bushings

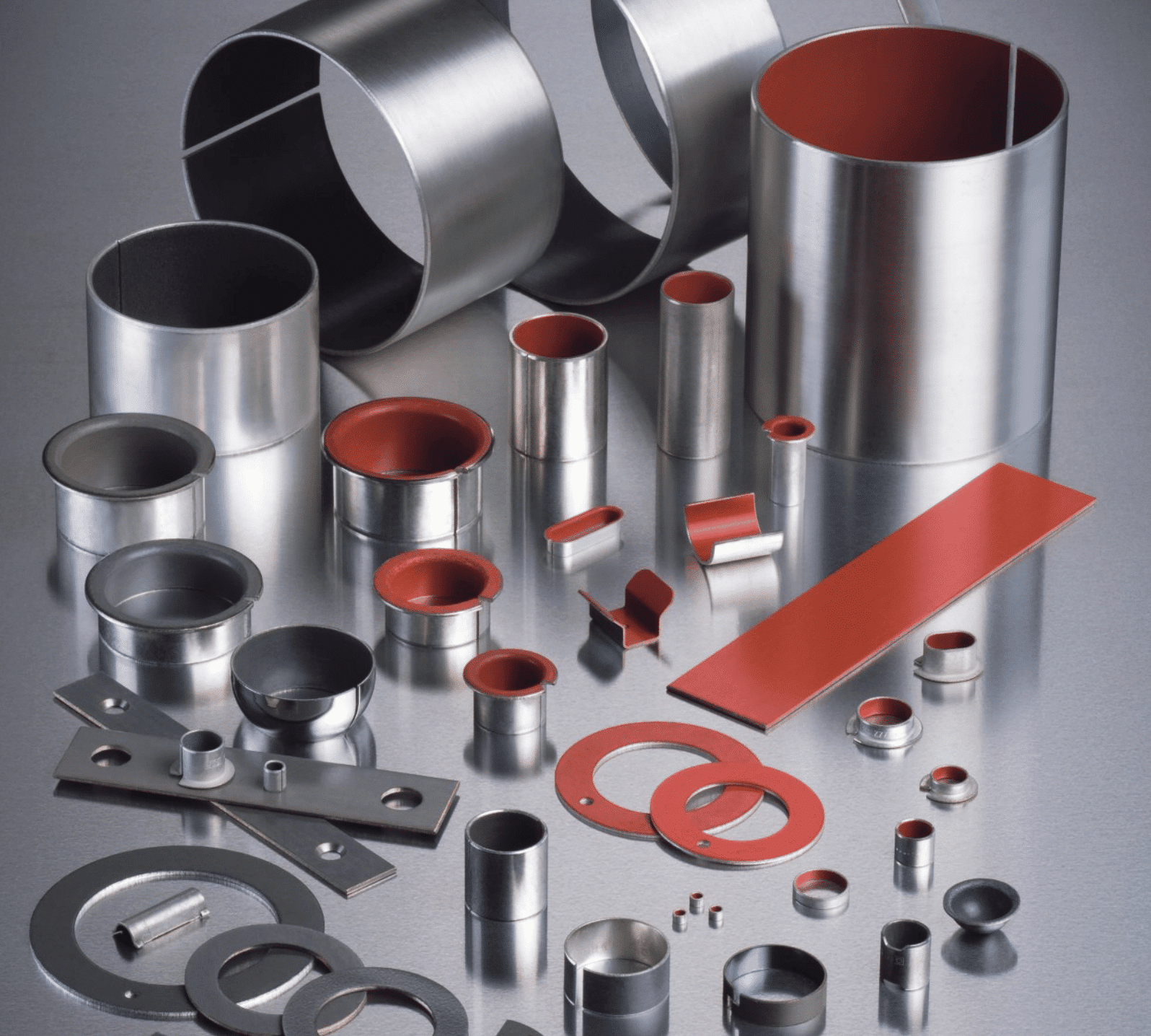

High performance plastic bushings are often confused with PTFE coated and metal backing bushings, which are much older technology.

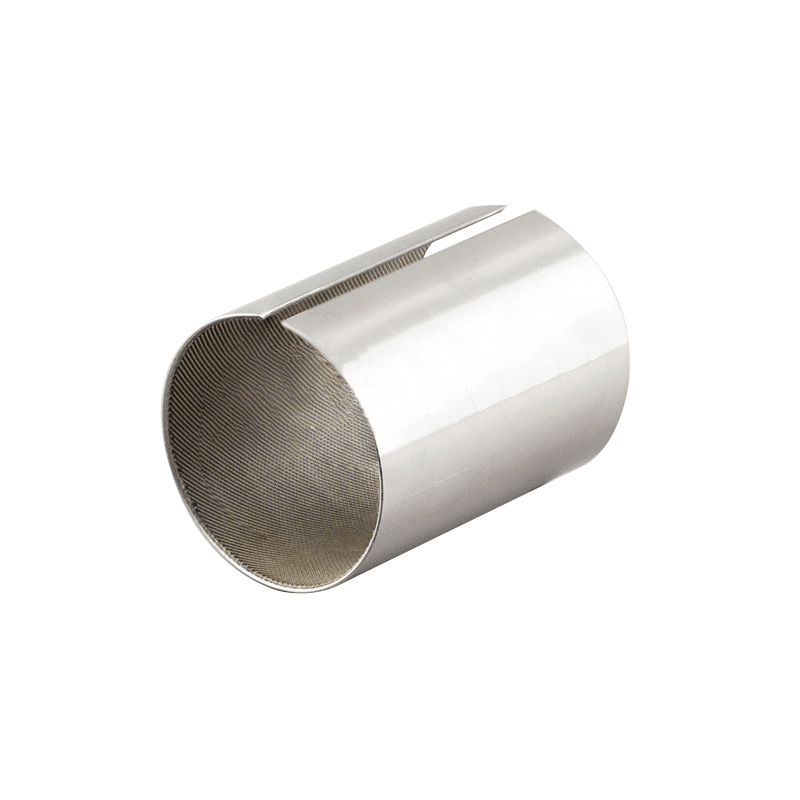

We manufacturer PTFE lined steel backed bushing tailored to your individual needs.

PTFE (polytetrafluoroethylene) bushings

Our PTFE-based metal-polymer materials offer exceptionally low friction and high wear. Superior PTFE and thermoplastic-based metal-polymer bearings.

PTFE (polytetrafluoroethylene) bushings are commonly used in many industrial and engineering applications due to their low friction, chemical resistance, and dimensional stability. If you are looking for alternatives to PTFE bushings, some of the options you can consider include:

Nylon Bushings: Nylon is a lightweight and durable material that is often used as an alternative to PTFE in low-load applications. Nylon bushings offer good wear resistance and are relatively inexpensive compared to PTFE.

Polyurethane Bushings: Polyurethane is a versatile plastic that offers a good balance of wear resistance, load-bearing capacity, and low friction. It is often used in applications where a soft, flexible bushing is required.

Bronze Bushings: Bronze is a metal that is known for its high strength and durability. Bronze bushings are commonly used in applications that require high load capacity and good wear resistance.

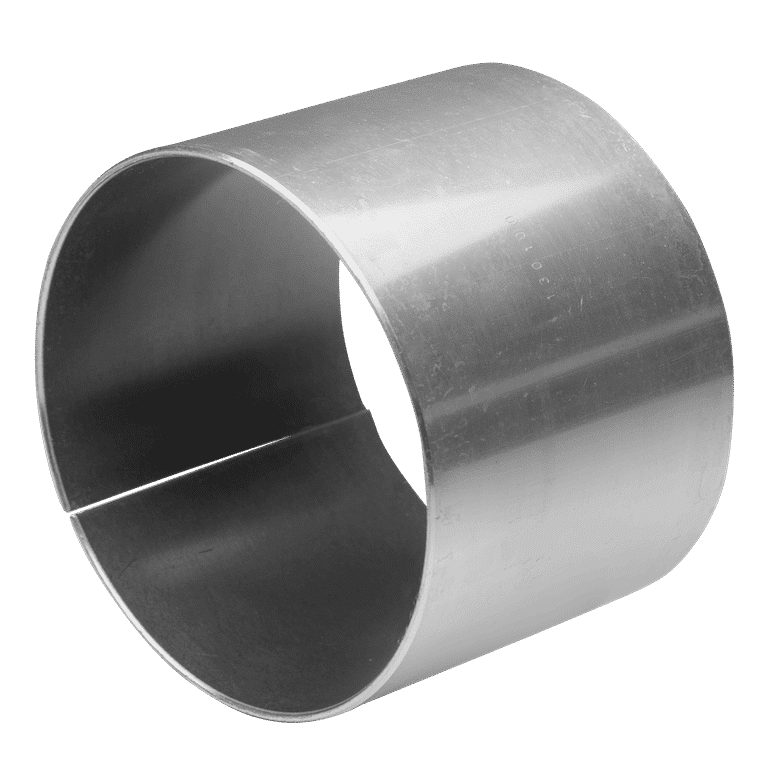

Steel Bushings: Steel is a strong and durable material that is often used in high-load applications. Steel bushings are typically more expensive than other alternatives, but they offer excellent durability and wear resistance.

Fiber-Reinforced Plastic Bushings: Fiber-reinforced plastic bushings are made from a composite material that combines plastic with fibers such as glass or carbon. These bushings offer good wear resistance, high load capacity, and low friction.

Each of these alternative materials has its own unique advantages and disadvantages, and the best choice for a particular application will depend on factors such as load capacity, operating temperature, and environmental conditions.

With excellent bearing quality to promote the progress of modern industry

Here are the four main reasons to replace PTFE lined liners with plastic liners for greater design flexibility.

1. Thinner wear surface

The PTFE lined sleeve consists of a metal sheath and a very thin polymer coating (PTFE) applied inside. These types of bushings typically have a maximum wear surface of 0.06 millimeters (0.002 inch), but when the PTFE coating is broken during operation, the metal coating is exposed. This creates a metal on metal effect between the sleeve and the shaft and can cause serious damage. This problem often occurs when there are high edge loads or oscillating movements.

By comparison, plastic bushings are made of advanced synthetic compounds that contain solid lubricants embedded in millions of tiny chambers throughout the material.

During operation, lubricant is transferred to the shaft in order to lower the coefficient of friction and wear. Unlike PTFE-lined bushings, plastic bushings eliminate the risk of metal-to-metal contact. This is a great advantage as the acceptable wear can be determined by the type of application (as opposed to the PTFE lined bushing which fails when the wear rate exceeds 0.06 millimeters).

2. Increased weight

Bushings lined with PTFE weigh more than plastic bushings. Using a heavier bushing will require more energy for the bushing to work, regardless of the material. This can be particularly problematic in automotive, aerospace, recreational vehicle, and bicycle applications.

In contrast, plastic bushings are lightweight, which helps to reduce fuel consumption and carbon dioxide emissions. The reduced weight can also help to reduce the emission of carbon dioxide, decrease masses and, consequently, decrease energy consumption.

3. No corrosion or chemical resistance

The metal shell of a PTFE coated bushing is not ideal for applications where water or caustic chemicals are present. In these types of applications, PTFE coated bushings can rust, corrode, contaminate sensitive areas, and eventually fail. Since plastic bushings are made only from high performance polymers, they offer both corrosion and chemical resistance and work unaffected in these types of environments.

4. No resistance to biofuels

The trend towards increasing use of biofuels and biodiesel creates problems with PTFE lined liners; After limited exposure to moisture, parts of the metal sleeve cover may start to peel off.

However, these types of applications open up new doors for plastic sleeves. As they are corrosion resistant, the plastic bushings remain intact, despite the fact that biodiesel tends to absorb a lot of water.

Seek bearings solutions to meet stringent performance requirements and quality expectations.

If you are looking for an alternative to PTFE-lined steel bushings, some options you can consider include:

Bronze Bushings: Bronze is a high-strength metal that is commonly used in applications that require high load capacity and good wear resistance. Bronze bushings can be a good alternative to PTFE-lined steel bushings because they offer good corrosion resistance and low friction.

Polyurethane Bushings: Polyurethane is a versatile plastic that offers a good balance of wear resistance, load-bearing capacity, and low friction. It is often used in applications where a soft, flexible bushing is required.

Nylon Bushings: Nylon is a lightweight and durable material that is often used as an alternative to PTFE in low-load applications. Nylon bushings offer good wear resistance and are relatively inexpensive compared to PTFE.

Fiber-Reinforced Plastic Bushings: Fiber-reinforced plastic bushings are made from a composite material that combines plastic with fibers such as glass or carbon. These bushings offer good wear resistance, high load capacity, and low friction.

Ceramic Bushings: Ceramic bushings are made from a hard, wear-resistant material that offers good load capacity and low friction. Ceramic bushings are typically more expensive than other alternatives, but they offer excellent durability and wear resistance in high-temperature applications.

Each of these alternative materials has its own unique advantages and disadvantages, and the best choice for a particular application will depend on factors such as load capacity, operating temperature, and environmental conditions.

Well-designed, reliable, quality-bearing bushing solutions

“Viiplus’ quality standards and expectations are very high because we operate in challenging markets that require well-designed, reliable, quality solutions.” It doesn’t matter where you go.While there may be differences in customer service, sales, and vendor interaction, the standards for quality are very consistent.

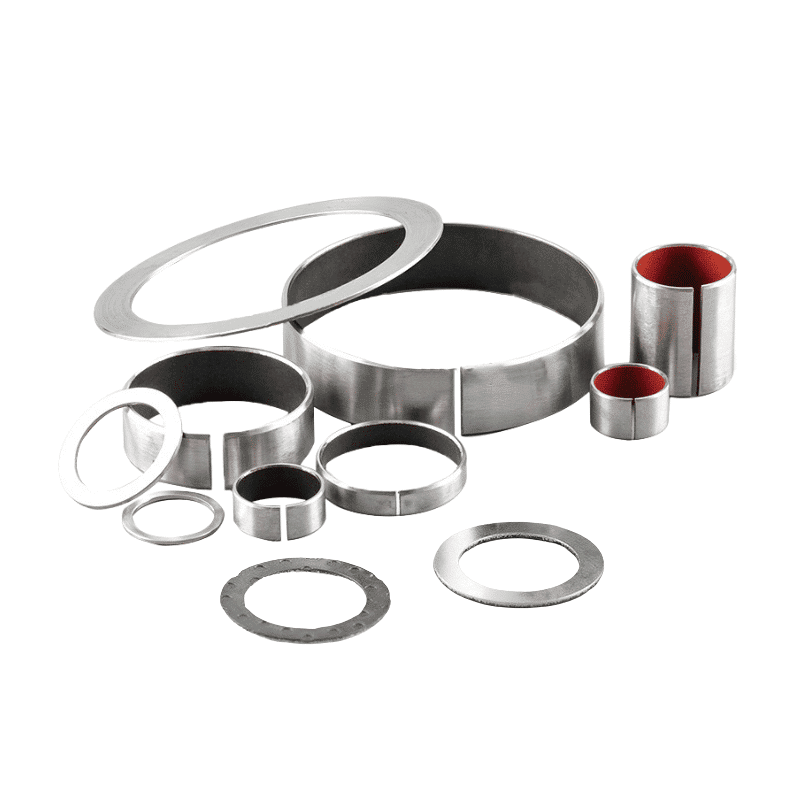

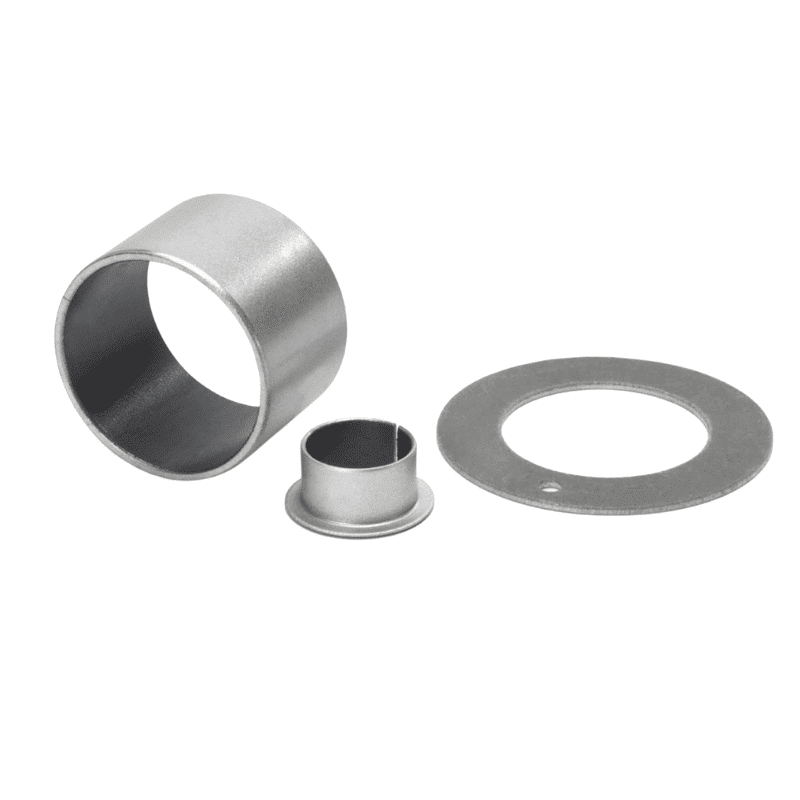

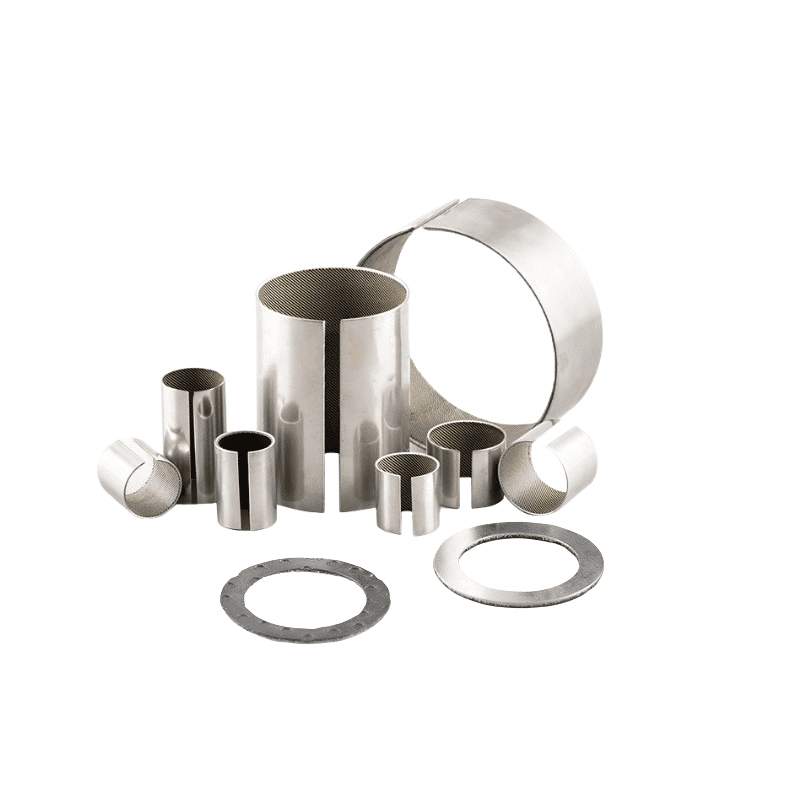

PTFE (Polytetrafluoroethylene) bushings are a type of self-lubricating bearing made of a metal shell with a PTFE lining. They are used in a variety of industrial and mechanical applications where low friction and high wear resistance are required.

The metal shell of a PTFE bushing provides support and rigidity, while the PTFE lining provides a low-friction surface that reduces wear and tear on moving parts. The PTFE material has a very low coefficient of friction, meaning that it requires very little lubrication to operate smoothly. This makes PTFE bushings ideal for use in applications where traditional lubrication methods are not practical or where a clean, lubricant-free environment is required. PTFE bushings are also resistant to a wide range of chemicals and high temperatures, making them suitable for use in harsh operating environments. They are commonly used in applications such as automotive suspension systems, robotics, and medical equipment.

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Browse Custom Bearings

Browse, get a quote and order products easily in Maintenance-free, self-lubricating eCatalog

Cost-effective,Browse Custom Bearings. Discuss your project with a bushing bearings expert. Providing high-performance bushing parts for your application. Along with our standard PTFE plain bearings and bushings, custom bushing are produced daily. We manufactures the exact sleeve bearing, or bushing, that you need at a low cost.