What are the engineering plastic bearings? Bearing Selection & Use Attention

Plastic plain bearing, plastic linear bearing, plastic joint bearing, plastic deep groove ball bearing

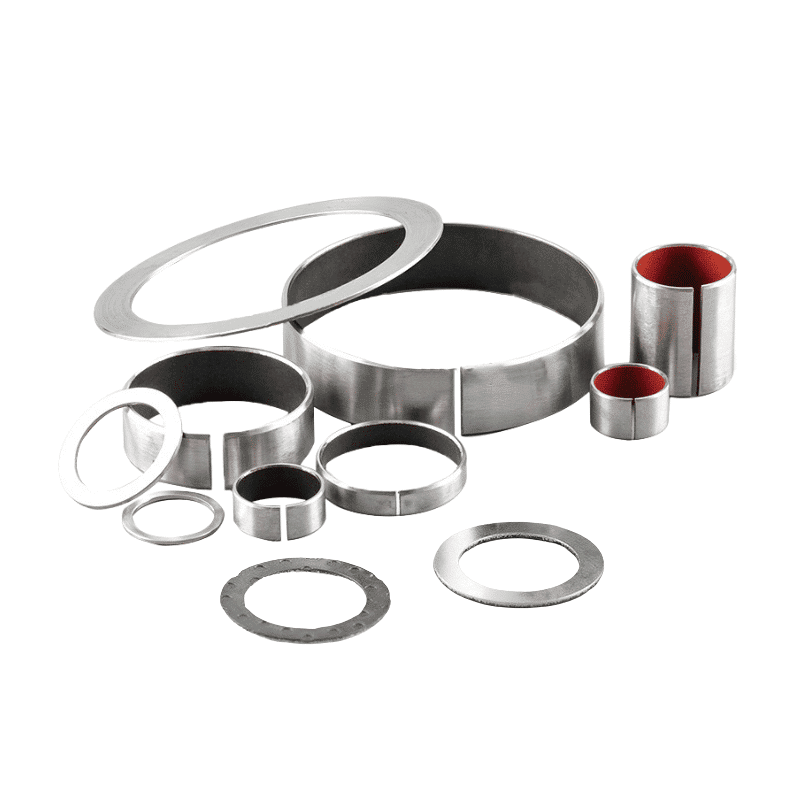

Maintenance-free plain bearings bushing

Viiplus offers a growing portfolio of plastic bearings products and services to keep industries moving efficiently and reliably. We bring to life know-how and innovation, providing true marketplace advantage.

Team up with us to transform your bearings

We are specialized in bearing industry for many years and have rich experience.

Discover new bearing business models, explore opportunities for efficient maintenance and find information about remanufacturing and customization of your plastic bearings.

Precision plastic bearings

- Precision plastic bearings are better than traditional plastic bearings in terms of precision, roughness and tolerance.

- The steel materials used in precision plastic bearings, injection molding equipment, process flow and tasting standards are fully European standards, and every process is well controlled.

- On the basis of maintaining some of the traditional advantages of plastic bearings, it can be applied to some extreme conditions such as precision, high-speed operation, cold resistance and high temperature.

Corrosion resistant plastic bearings

Corrosion-resistant plastic bearings have a variety of material solutions for those different application conditions, even in the most severe acid/alkali/salt/solvent/oil/gas/seawater erosion can still run freely to ensure ideal durability Sex and life expectancy.

Acid and alkali resistant plastic bearings

Acid and alkali resistant plastic bearings, HDPE, PE, UHMWPE and other materials have proven to be used in relatively weak acid-base cross-environment (30% CuCl2 solution and 30% NaOH solution test OK), and can be used in strong acid and strong alkali environments PVDF and PTFE materials. Of these materials, PTFE can be used in all concentrated acid and alkali situations, even in strong acid environments such as HF and fuming sulfuric acid and nitric acid (above 98%).

Plastic bearing seat and plastic outer spherical bearing

Plastic seated bearings have properties that other plastic bearings do not have, such as light weight, easy installation, corrosion resistance, maintenance-free, etc., and they also have the unique performance of vibration reduction and impact resistance that commonly used cast iron seats or stamping seats do not have.

Plastic bearing selection

With the continuous development of various new plastic materials, this type of bearing is increasingly being used in various projects.

Engineering plastic bearings have the following advantages over metal bearings:

- Lubricating material, long service life

- Sliding bearings will not rust and are resistant to corrosion during use, while metal bearings are easy to rust and cannot be used in chemical liquids;

- Sliding bearings are lighter than metal, which is more suitable for modern lightweight design trends;

- The manufacturing cost of plastic sliding bearings is lower than that of metal;

- Plastic bearings are processed by injection molding and are more suitable for mass production;

- Plastic sliding bearings have no noise during operation and have a certain vibration absorption function;

- Plastic sliding bearings are suitable for high and low temperature work -200~+250 degrees;

Select your plastic bearings to meet your requirements

The plastic bearings currently used can generally be divided into plastic rolling bearings and plastic sliding bearings;

The working principle of plastic rolling bearing and plastic sliding bearing can be distinguished by the name. The friction that occurs when plastic rolling bearing is working is rolling friction, and what occurs when plastic sliding bearing is working is sliding friction;

The size of the rolling friction mainly depends on the manufacturing accuracy;

The friction of plastic sliding bearings mainly depends on the material of the sliding surface of the bearing.

Help you find the right bearings solution for your specific application.

Ready to Talk With

Our Bushing Bearing Expert Today?

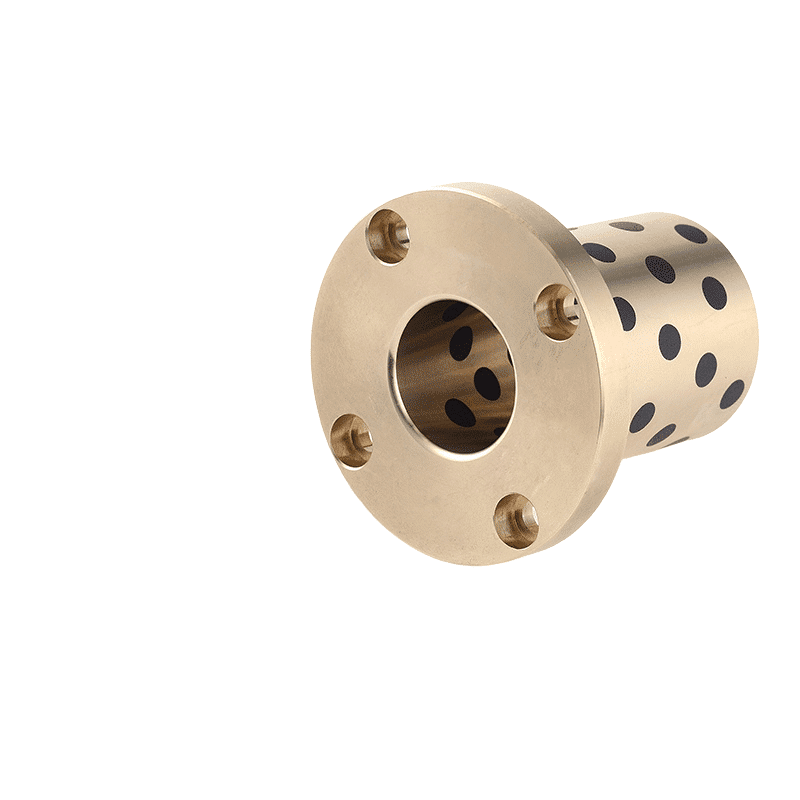

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com