How does the polymer plain bearing influence the shaft selection?

sleeve bearing with flange, mm

Maintenance-free plain bearings bushing

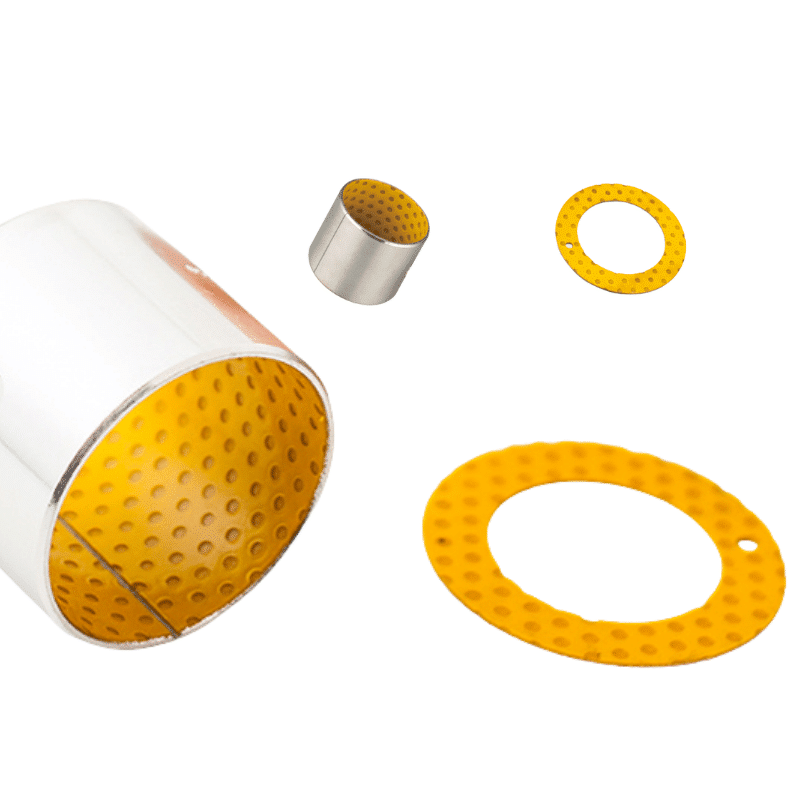

Lowering costs and increasing service life without lubrication and reducing maintenance work – everything is delivered immediately from stock – that is the core idea and goal of all polymer plain bearings

Selecting the right sliding bearing for the equipment and application is essential to the successful operation of that equipment.

- Cost factors

Cost reduction is very important to most companies.Whether low-cost shaft materials can be used depends on the choice of bearings.

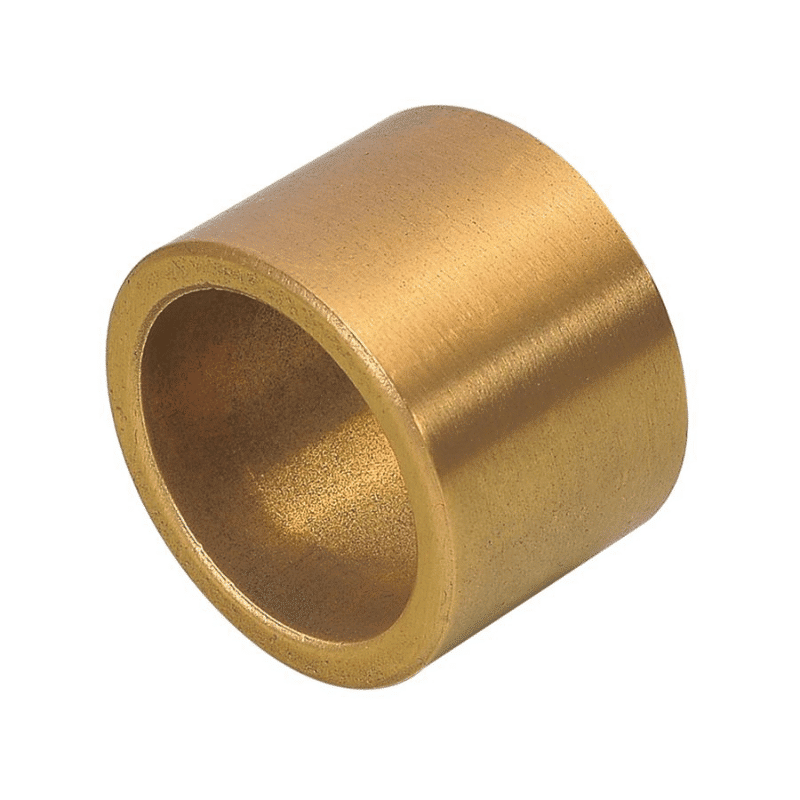

For example, ball bearings require very hard (60HRC or higher) and smooth shafts.Bronze bearings are similar: the shaft must be harder than the bronze material used.Because of these requirements, the choice of axes is very limited.Cheaper shaft materials may not be suitable for these applications.

Plastic bushings offer more options as they can be matched with many different shafts.

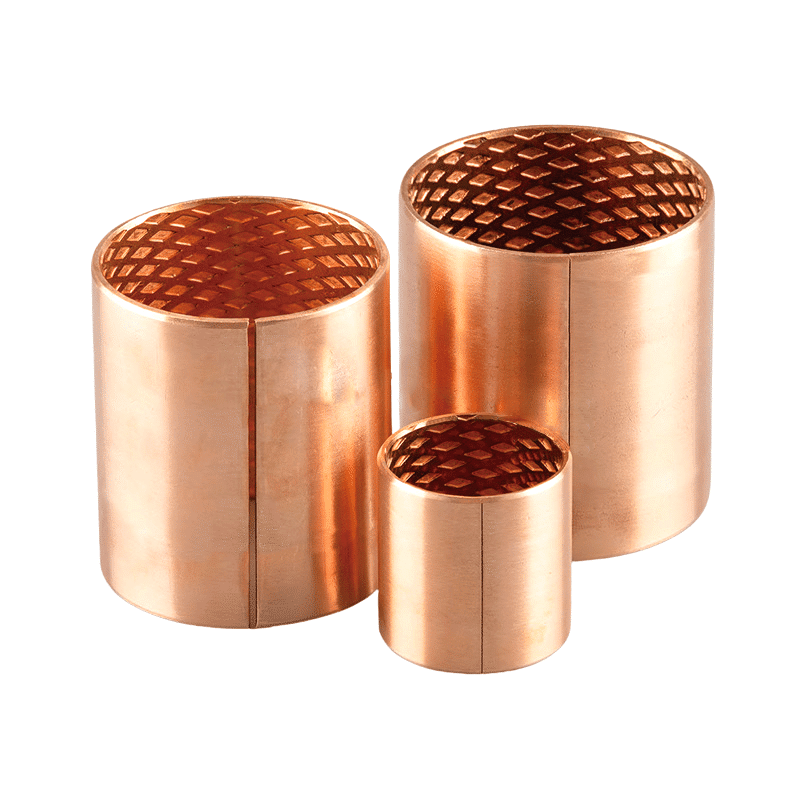

Plain bearings can be made of many materials:

So you can use the unbeatable cost shaft to match the bearing material most suitable for the application and/or the required service life.The service life of bearings and shafts only needs to be as long as the service life of the entire machine/equipment.

Driving the Future of Plain Bearings

Our growing portfolio of plain bearings & bushings is designed to meet our global customers’ evolving needs.

Bushings Quality and environmental respect are essential to our core values

- Abrasive resistance

In addition to cost factors, there are many other factors to consider when designing shafts for bearing systems.If not considered, many factors will affect the performance of bearings.If the shaft is too rough, wear will be a problem.A shaft that is too rough will act like a file to scrape small particles off the bearing surface during movement.If the shaft is too smooth, the bearing and shaft may stick together, resulting in increased friction.Stick-slip (characterized by a large shrill noise) can become a problem if static and dynamic friction are very different and there is adhesion on the mating surface

Another important factor to consider is how hard and soft particles can damage bearings and shafts.If particles enter the bearing and its mating surface, both will be damaged due to increased wear.Dirt, dust and paper fibers can cause problems.Bearings that lubricate themselves by embedding a solid lubricant last longer in dirt because there is no grease or lubricating oil in the bearing.This means that dirt particles do not enter or stick to the shafts and bearings (for example, you can look at a bicycle chain with a lot of lubrication).You can also use cheaper shafts, even in dirty applications.There are many shaft materials on the market, each of which will have a different impact on the wear of bearings.Shaft materials include aluminum, surface hardened steel, stainless steel and chrome-plated steel.Finally, service conditions and service life requirements will determine the shaft to be used.When selecting the appropriate sliding bearing, basically any standard type of shaft can be used.

Bearing shaft selection

Keeping the Bearing in Motion

Polymer plain bearings are available in three forms, sleeve bearings, flanged bearings and thrust washers.

Advancing Our Position as a Global Bearing Leader

We offer bushing & bearing of quality designed to improve the reliability and efficiency of industrial equipment and machinery that keep industry in motion.

Explore more plain bearings to meet your requirements

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com