Saves You Time & Money In Self-lubricating Bearings Research, Design & Production Costs.

How do you mount an plain bearing?

Reliable & Professional Plain Bearing Solution Supplier

Bushings and Plain Bearings – Mounting

Skill and care in assembly are prerequisites for a long bearing life. In addition, cleaning and understanding the causes of premature bearing failure can also help.

Check that the support surface (shaft seat) and other components, such as the housing, are clean, deburred and do not contain abrasive particles. Also check the shaft for sharp edges, burrs or surface defects, which can damage the sliding surface of the bushings. After cleaning and checking all components, the bushing is ready to be installed.

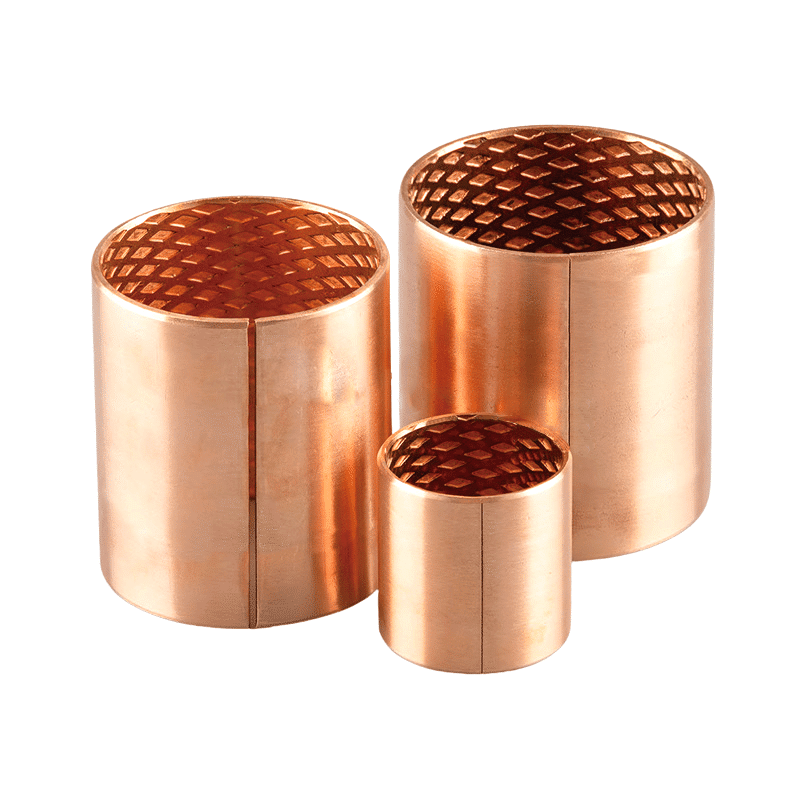

Low-maintenance and maintenance-free plain bearings

Long-Lasting, Low-Wear Sliding

One of the factor that have influence on reliable work of bearing and its life is properly conducted mounting process.

Before a bearing is ready to be mounted, should confirm:

- Housing and shaft are clean, undamaged, and dimensionally accurate

- Lubricant is clean and correctly specified

- Necessary tools and equipment are on hand

- Proper safety precautions are in place

Before starting the installation, check the bearing seats and stops, remove any damage from the surfaces of the seats and, if necessary, clean it with Antikor kerosene. As a rule, new bearings should not be washed, but in the case of used bearings, they can also be cleaned with Anticor kerosene. Before installing the bearings, the seats and stops should be lightly greased with oil or grease to facilitate assembly and protect surfaces from corrosion.

High performance self-lubricating bearings

Self-Lubricating Sliding Material, Factory Price, Contact Us!

Reliable, Cost-efficient Bushing & Bearing Solution

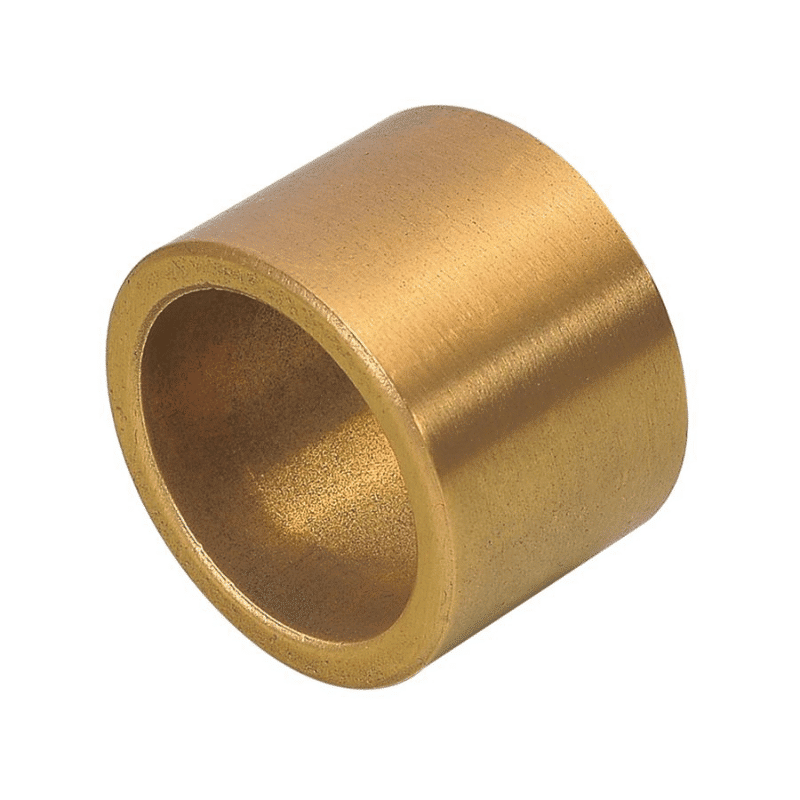

Plain Bearing Mounting Press-In Force And Joint Pressure

Press-in force and joint pressure are interdependent. The connection pressure occurs between the housing bore and the surface of the socket jacket. It can be understood as a measure of how secure the socket is in the housing. Joint pressure, along with other factors, affects the insertion force.

Design and layout of bearing assembly: housing

The bushings are pressed into the housing and fixed radially and axially. No further action is necessary.

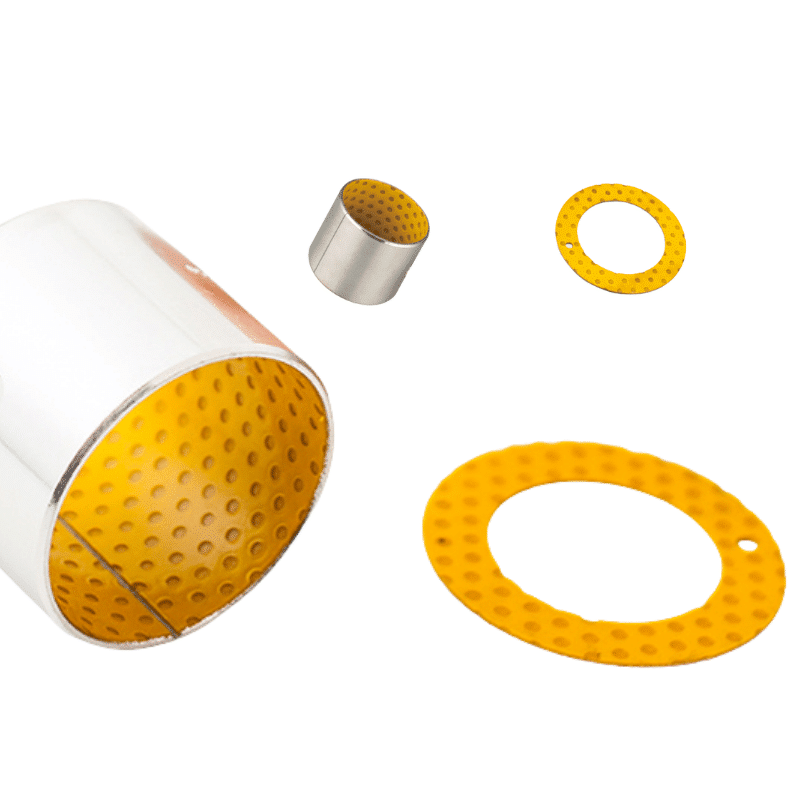

Calibrating the bearing bore after mounting

Plain bearings are ready for installation on delivery and should only be calibrated if the tighter tolerance cannot otherwise be achieved.

Bearing Mounting

First & most reliable self-lubricating bearings

To install bushings, with or without flange, Viiplus recommends using an assembly trolley with the respective shaft tolerance in particular for:

Explore more bearing mounting method

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com