How can plain bearings manage without lubrication?

Self-lubricating, maintenance-free plain bearings

Bearing design, Selection support

Application performance can be improved by eliminating lubricants as many greased and oiled bearings fail prematurely due to inadequate lubrication and lack of regular or improper maintenance. Work with Viiplus and get the performance you need for your application without expensive lubrication systems and lubricants.

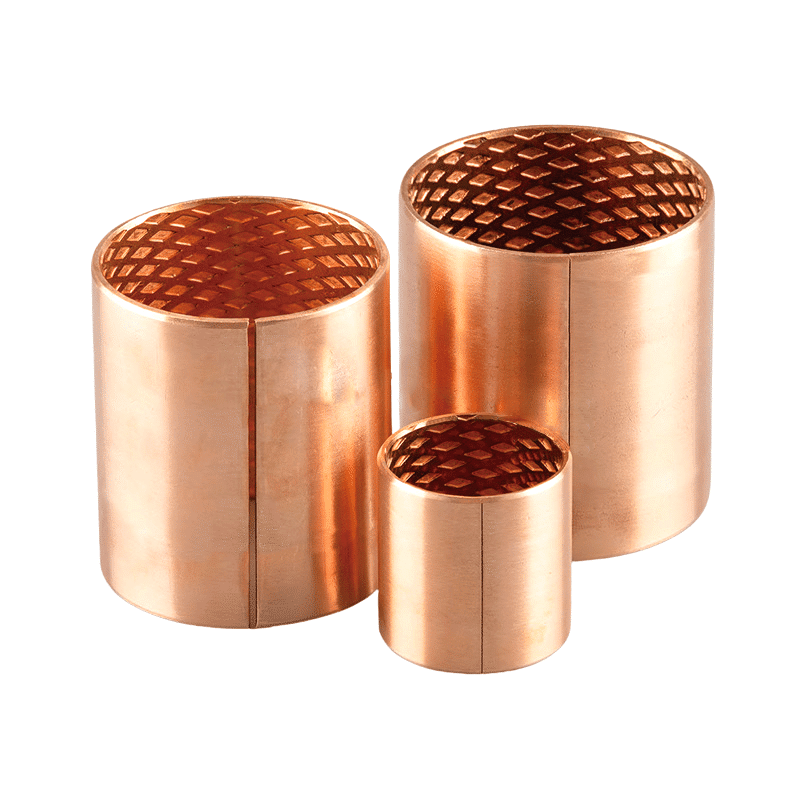

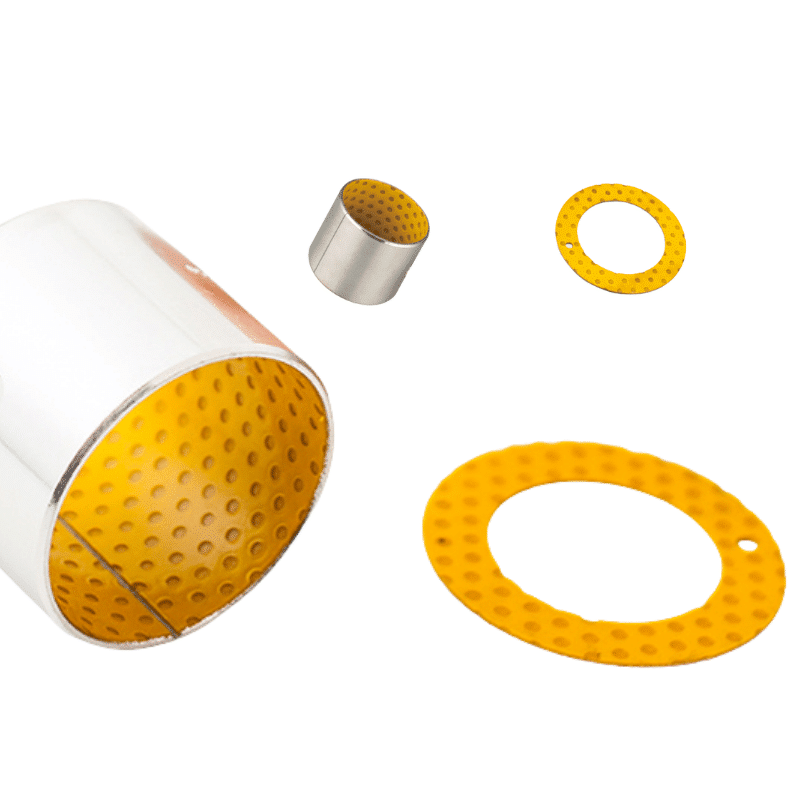

Due to the special structure of the materials, which usually consist of a thermoplastic matrix, fiber reinforcements and the so-called solid lubricants … the already good wear and friction properties of the matrix or the base material are further optimized by the solid lubricants. Sufficient solid lubricant particles are always present on the bearing surface during operation. Additional external lubrication with grease or oil is usually neither necessary nor practical.

Specializes in a variety of bearing manufacturing delivering bearings critical solutions to our customers.

Superior quality, excellent reliability and high performance

These PTFE plain bearing materials enable extremely low coefficients of friction for plain bearings and rod ends as well as bushings, washers and strips while ensuring low wear and very long life cycles.

Maintenance-free plain bearings significantly reduce lubrication and maintenance costs as they require no oil or grease and are also very environmentally friendly.

Custom self-lubricating bearings products are also available

Viiplus are the recognized bearing specialists and distributors for many industry recognized manufacturers. We offer genuine, high quality bearings, backed by a full manufacturer’s warranty.

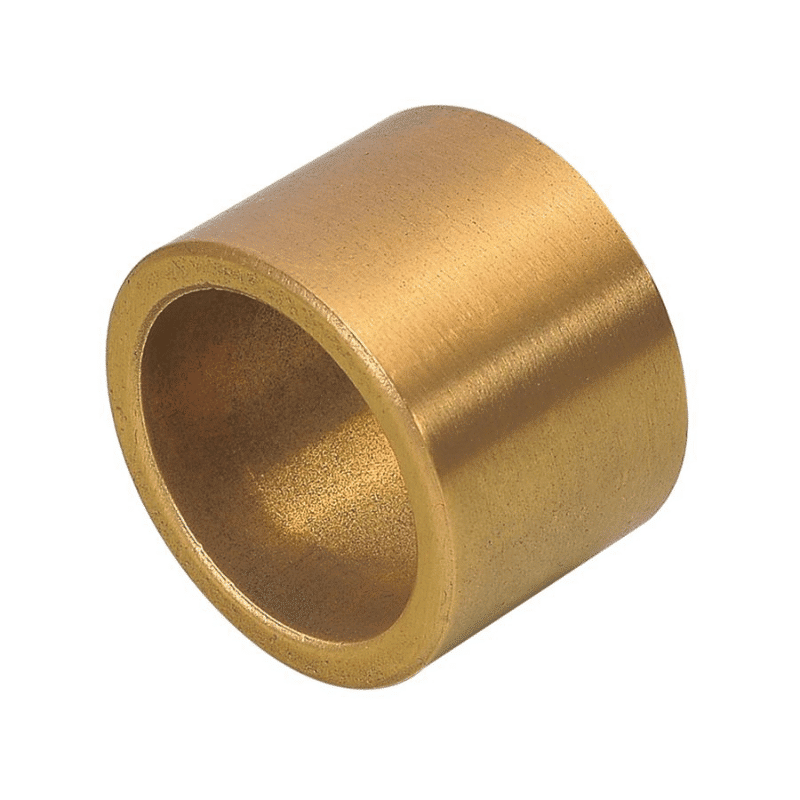

Self-lubricating bearings, as the name suggests, provide their own lubrication during operation without requiring the application of grease or lubricating oil.

Here are some of the reasons and benefits when lubricants are eliminated

- Periods of regular maintenance for relubrication can reduce operating efficiency which increases TCO (Total Cost of Ownership) due to stoppage and downtime of the machine

- Potential harm to the bearings recognized to premature equipment failure can be caused by using an incorrect lubricant or topping up with an incompatible lubricant

- Additional costs are incurred due to machining of grease paths or oil ways in the shaft or housing, as well as the expensive sealing systems needed to retain the lubricants

- Additional savings result from the elimination of lubricants and lubrication systems, as the costs for lubricants can rise quickly and the overall costs for maintenance and project construction increase

- Improve machine efficiency by eliminating the loss of power due to surface contact of lubricating seals with the shaft

- Better for the environment due to the risk of soil contamination from relubrication or oil changes in the field – the environmental aspect should be emphasized

Bearing Lubrication Free

Plain Bearing Design and Service Life

Self-lubricating bearings are also referred to as maintenance-free or grease-free bearings because they do not require relubrication or lubrication. An example of a self-lubricating bearing is our grease-free bearing.

Welcome to bronzelube.com

Compared with normal plain bearings, our bearing are superior in wear resistance, seizure resistance and friction properties, and realize performance enhancement and maintenance-free devices.

Providing Customized Self-lubricating Bearings Solutions For Many Years

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com