Innovation Plastic Bushing Solution, Providing True Marketplace Advantage.

How long is the service life of plastic bearings?

Because the service life of any bearing is affected by the actual working conditions, such as working load, speed, temperature and comprehensive environmental factors;Therefore, it is impossible for any bearing manufacturer to calculate the accurate service life without actual use verification. It can only estimate the service life of bearings under similar cases through existing use cases.

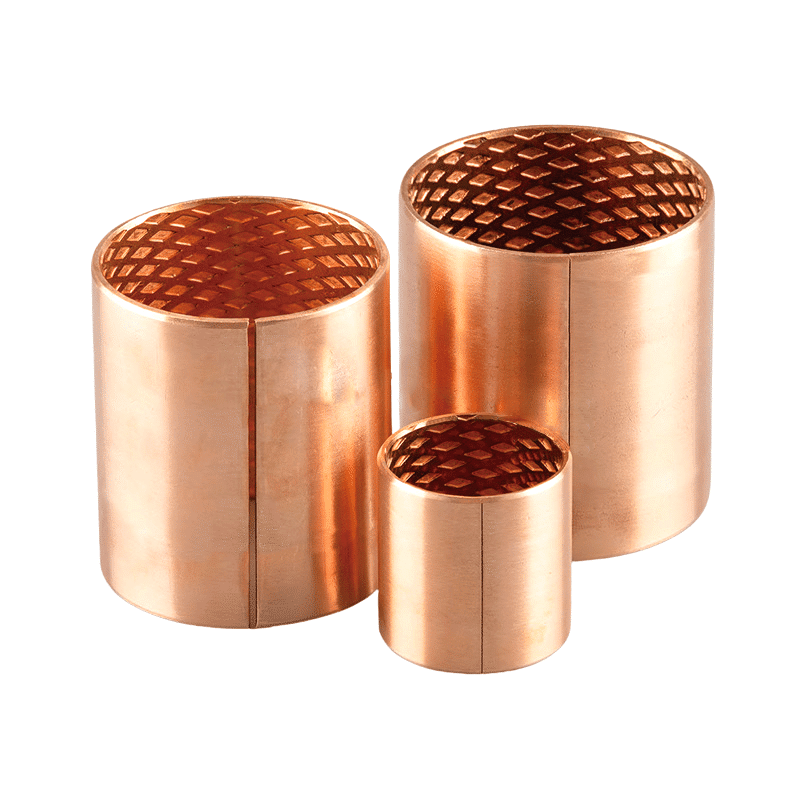

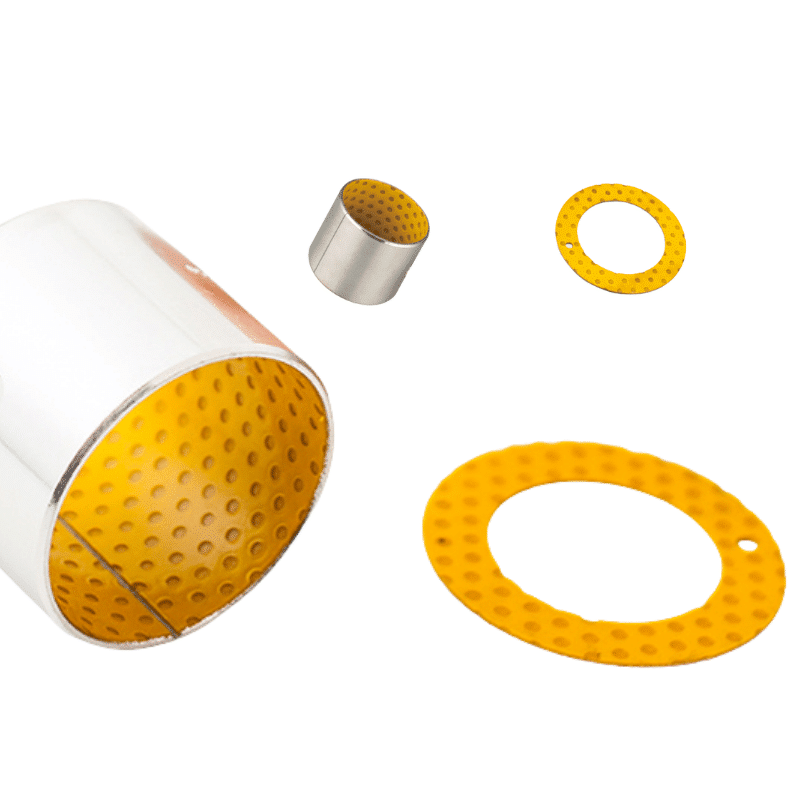

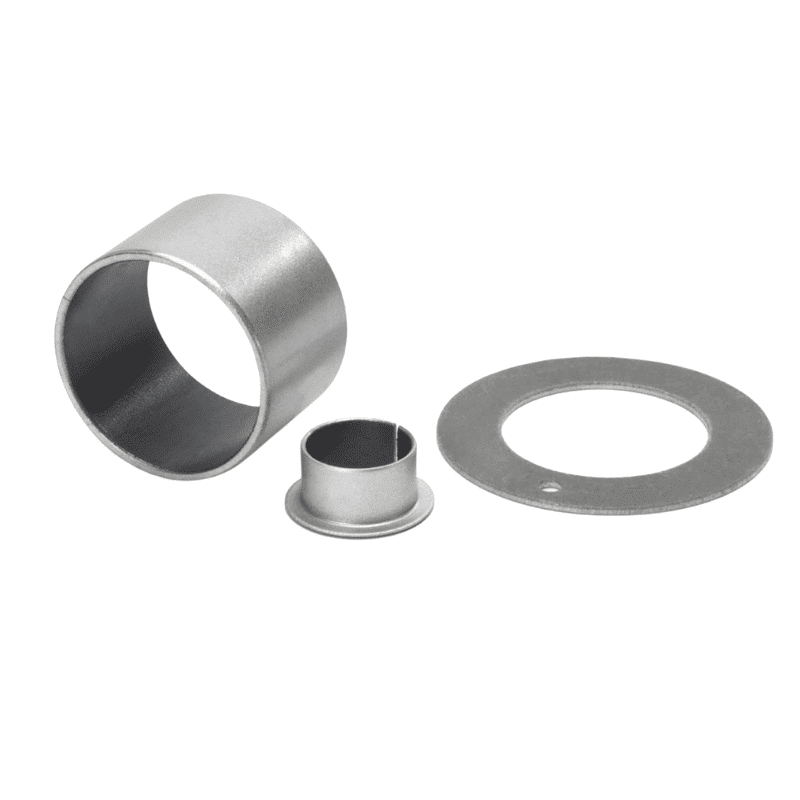

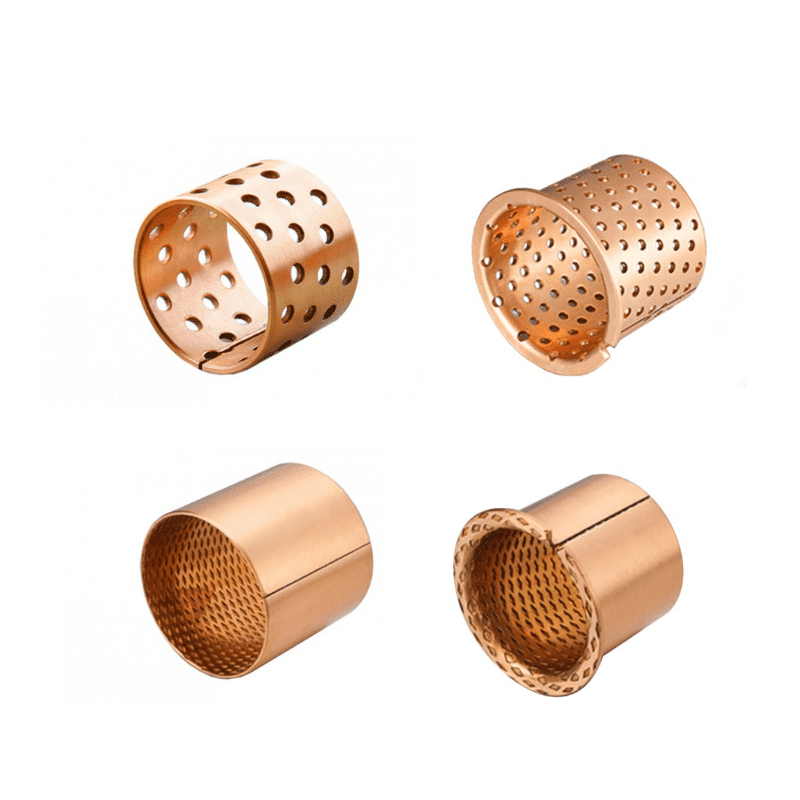

Maintenance-free plain bearings & plastic bushings

sleeve bearing with flange, mm

The bearings keep industries moving efficiently and reliably.

How about the aging resistance of plastic bearings?

Due to the use of high-performance engineering plastics as the basic raw materials, anti-aging UV agent is implanted through material modification technology to improve the comprehensive anti-aging performance of plastic bearings.Anti-aging ability of plastic bearings: Indoor: 20~30 years;Outdoor for 15 to 25 years.

Choosing the right plastic bearings material is critical because the service life of the bearing is affected by relative motion.

Plastic Bushings Bearings

Factory producing in low cost and stable quality!

What are the most economical models of plastic bearings?

Price from low to high EPF(maximum service temperature 100℃),EPTH(maximum service temperature 80℃), EPGH(maximum service temperature 100℃), EPJ3 (maximum service temperature 80℃), EPM (maximum service temperature 80℃)

Which types of plastic bearings have better corrosion resistance?

Corrosion resistance from low to high Eph, EPX, EPS, EPXA

Which commonly used models of plastic bearings belong to high temperature products?

EPH (long-term operation up to 200 ° C), EPXA(long-term operation up to 200 ° C), EPX(long-term operation up to 250 ° C), EPS (long-term operation up to 260 ° C)

Find More FAQS For Your Plain Bearings & Plastic Bushings.

Which types of plastic bearings are suitable for underwater operation?

- EPH Plastic Bearing

Which types of plastic bearings conduct electricity?

- EP09 plastic bearing surface resistivity ≤1000Ω

Which type of friction coefficient is lower in plastic bearings?

-

Friction coefficient from low to high EPS, EPJ, EPT, EPA, EPX

Which types of plastic bearings are suitable for working at heavy loads and low speeds?

- Loading capacity from high to low EPX, EPXA, EPW1, EPW, EPJ

Which types of plastic bearings are particularly suitable for rocking motion under heavy loads?

Especially suitable for rocking motion EPG1, EPA1, EPXA5

Why is the outer diameter of the plastic bearing not marked with tolerance?

Because the plastic bearing is processed by injection molding process, the product is easy to produce ellipse phenomenon in the cooling process from high temperature to room temperature, plus the plastic bearing itself has a certain elasticity;These reasons lead to the fact that the outer diameter of the plastic bearing cannot be accurately measured by its own state.However, Viiplus considers the actual needs of the product when designing the products of each size. The outer diameter of the product is determined by the mold size to ensure that the product has the necessary interference size during installation, so as to ensure that the product is not easy to loosen or fall off during use.

Why is the inside diameter dimension tolerance of plastic bearings larger than that in the product catalog?

Tolerance value after dimension;The tolerance class of the standard ring gauge is H7(ISO3547-1), and the inner hole is tested by plug gauge.The rest are measured by digital calipers since the inner diameter dimension tolerance of plastic bearings is not measured under free state, but by pressing the plastic bearings into the standard ring gauge and measuring the average value under state.

What are the requirements for the recommended mount holes and shafts for plastic bearings?

Plastic bearings are recommended to use seat holes are H7 tolerance, shaft diameter is H6 ~ H9;The most common and ideal shaft material is hard chrome plating on the surface, and the most ideal surface finish is Ra0.4~0.8

Ready to Talk With

Our Bushing Bearing Expert Today?

A BUSHINGS EXPERT CAN HELP YOU DETERMINE WHICH BUSHINGS TYPE IS SUIT FOR YOUR APPLICATION.

Join Over 500,000 Customer Enjoying Buying Self-lubricating Bronze Bushing Parts Now

Always tested. Always proven. Always Bronzelube.com