Deep Groove Ball Bearing Supplier

Beautifully crafted leather products.

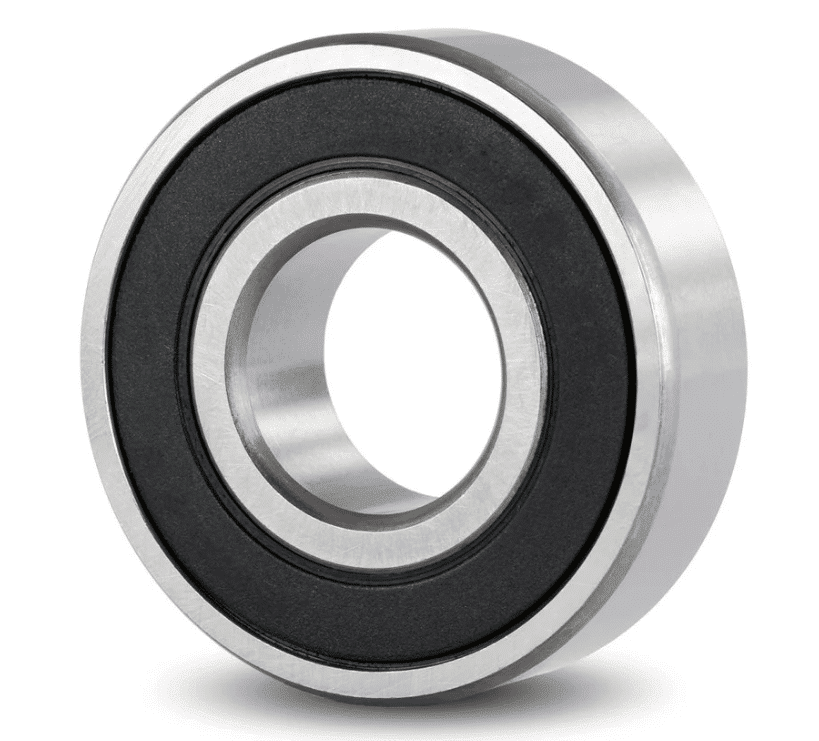

Deep groove ball bearings are the most common type of ball bearing. Production and Supply – Wide Range of Industrial, Automotive and Ball Bearings Globally. Quality and Precision. Developed Logistics. We specialize in supplying various types of bearings for buyers. Contact us Now! Bearings tested by you are better than our countless advertising by us. OEM&ODM Bearing. Bearing Manufacturer – Only focus on wholesale, is specializing in providing all types of bearings for buyers, large-scale end users. Part number 6005 Description Deep groove ball bearing, 6005 bearing is a deep groove ball bearing, inner diameter 25mm, outer diameter 47mm, thickness 12mm. The 6005 bearing is a 25 mm Ball Bearing that can be used in many rotary and factory automation applications. The 6005 Deep Groove Ball Bearings is an open style bearing. Bearing Price On request!

Deep Groove Ball Bearings Suppliers

Manufacturer of standard and custom precision deep groove ball bearings. Features include double and single row configuration. Miniature ball bearings are also offered. Available in metric and imperial sizes. Suitable for mute, special sealing, electric insulation, ultra-high speed and high/low temperature resistance applications.

Custom manufacturer of ball bearings including deep groove ball bearings

Manufacturer of radial deep groove ball bearings. Offers open and shielded large-sized ball bearings. Available with stainless steel material construction. Suitable for medical equipment, pump, and food processing, printing, and textile machine applications.

Understanding the 6005 Bearing: Dimensions and Supplier Insights

Bearings are essential components in a wide range of machinery and equipment, from simple household items to sophisticated industrial machinery. The 6005 bearing, in particular, is a popular choice for many applications. In this blog post, we’ll delve into the dimensions of the 6005 bearing and provide insights into selecting the right supplier.

1. 6005 Bearing Dimensions

The 6005 bearing is categorized as a deep groove ball bearing. It’s particularly known for its versatility and ability to handle both radial and axial loads. Here are its standard dimensions:

- Inner Diameter (ID): 25 mm

- Outer Diameter (OD): 47 mm

- Width (B): 12 mm

These dimensions can slightly vary based on the specific design or variant of the 6005 bearing. For instance, there are sealed, shielded, and open versions, each of which may have subtle differences in measurements. It’s essential to always check the exact specifications when purchasing.

2. Choosing a 6005 Bearing Supplier

Selecting the right bearing supplier is crucial. Here are a few factors to consider:

-

Quality: Ensure that the supplier adheres to international quality standards like ISO. A high-quality bearing will last longer and perform more efficiently.

-

Reputation: Research the supplier’s reputation in the market. Customer reviews, testimonials, and industry feedback can provide valuable insights.

-

Pricing: While cost shouldn’t be the only determining factor, it’s essential to find a supplier that offers competitive pricing without compromising on quality.

-

Variety: Ensure that the supplier stocks a wide variety of bearings, including different brands and types. This will allow you to choose the best bearing for your specific application.

-

Customer Service: A responsive and knowledgeable customer service team can make a world of difference, especially if you have questions or need guidance.

-

Delivery and Logistics: Check the supplier’s delivery times and shipping policies. It’s crucial to have a reliable supplier that can meet your delivery timelines.

3. Conclusion

The 6005 bearing is a versatile and widely-used component in many applications. Understanding its dimensions is the first step in ensuring you get the right bearing for your needs. Moreover, selecting the right supplier can make a significant difference in the quality and longevity of the bearing you purchase. Always prioritize quality, reputation, and customer service when making your choice.

Deep Groove 6005 Ball Bearings: An Essential Guide

When it comes to precision machinery and equipment, choosing the right component is essential for optimal performance. One such crucial component is the deep groove ball bearing, specifically the 6005 variant. In this article, we’ll dive deep into the specifications, features, and manufacturers of the 6005 deep groove ball bearings.

1. Introduction to the 6005 Deep Groove Ball Bearing

The 6005 bearing is a type of deep groove ball bearing, which is among the most common types of bearings used in various applications. Its design allows it to handle both radial and axial loads efficiently.

Specifications:

- Type: Deep Groove Ball Bearing

- Dimensions: 25mm x 47mm x 12mm (Inner Diameter x Outer Diameter x Width)

2. Features of the 6005 Bearing

-

Versatility: Due to its deep groove design, the 6005 bearing can manage both radial and axial loads, making it suitable for a wide range of applications.

-

Durability: Made from high-quality materials, these bearings are designed to last and offer consistent performance even in demanding conditions.

-

Low Friction: The design minimizes friction, which means less wear and tear and longer operational life.

-

Sealing Options: The 6005-2RSR variant comes with rubber seals (2RSR) on both sides, protecting the bearing from dirt, dust, and other contaminants. This enhances the longevity of the bearing, especially in harsh environments.

3. Leading Manufacturers of the 6005 Deep Groove Ball Bearing

While there are numerous manufacturers globally, always opt for those with a proven track record in quality and innovation. Some leading manufacturers include:

-

SKF: A renowned name in the bearing industry, SKF offers high-quality bearings with advanced technology.

-

FAG: Known for its precision engineering, FAG’s 6005-2RSR variant is especially popular for its durability and performance.

-

NTN: With a reputation for consistency, NTN bearings are trusted by professionals worldwide.

-

NSK: Another big player, NSK’s products are synonymous with quality and reliability.

-

Timken: A global leader, Timken offers a range of bearing solutions tailored to various needs.

4. Conclusion

The 6005 deep groove ball bearing, with its versatile design and robust construction, is indispensable in many industries. Whether you’re in manufacturing, automotive, or any other sector, understanding the bearing’s specifications and features can help you make an informed decision.

Furthermore, partnering with a reputable manufacturer ensures that you get a product that stands the test of time. Always prioritize quality, precision, and reliability when selecting your bearing supplier. After all, the performance of your machinery largely depends on the components you choose.

The “6005 2RS” designation refers to a specific type of deep groove ball bearing. Let’s break down the nomenclature and discuss its features:

1. 6005 Bearing

- Inner Diameter (ID): 25 mm

- Outer Diameter (OD): 47 mm

- Width (B): 12 mm

2. 2RS Designation

The “2RS” in “6005 2RS” stands for “Two Rubber Seals.” This means that the bearing has rubber seals on both sides to prevent the ingress of dirt, dust, and other contaminants. These seals also help retain the lubricant inside the bearing, ensuring smoother operation and longer lifespan.

Features of 6005 2RS Bearing:

-

Protection: The dual rubber seals offer added protection against contaminants, which can increase the bearing’s operational life, especially in environments where dirt and debris are prevalent.

-

Lubrication: The seals help in retaining lubrication, reducing the need for frequent re-lubrication and ensuring consistent performance.

-

Low Friction: The rubber seals, combined with proper lubrication, reduce friction, allowing the bearing to operate efficiently.

-

Versatility: Like other deep groove ball bearings, the 6005 2RS is versatile and can handle both radial and axial loads.

-

Noise Reduction: Sealed bearings tend to operate with less noise compared to open or shielded variants.

Applications:

The 6005 2RS bearing, with its sealing feature, is ideal for applications where the bearing is exposed to contaminants or where a longer maintenance interval is desired. This includes:

- Motorcycles and automobiles

- Electric motors

- Agriculture machinery

- Industrial equipment

- Home appliances

Conclusion:

If you’re looking for a bearing that offers protection against contaminants and reduced maintenance needs, the 6005 2RS deep groove ball bearing is an excellent choice. Always ensure you purchase from a reputable manufacturer or supplier to guarantee the quality and longevity of the bearing.

The Factors Affecting the Service Life of Rolling Bearings

Rolling bearings are pivotal components in a multitude of machines and equipment. Their proper functioning ensures smooth operation, reduces wear and tear, and extends the longevity of the equipment they’re part of. Yet, their service life can be influenced by various factors, ranging from installation methods to maintenance and even the environment they operate in. Let’s delve deeper into the significant factors that can affect the service life of rolling bearings:

1. Installation Factors

Conveyor Roller Bearing Housing Gland Installation: The manner in which the bearing seat gland is installed can have a direct impact on the bearing’s performance. An improper installation can alter the radial clearance of the bearing. If this clearance is too small, the bearing can overheat, exacerbating wear and possibly leading to bearing seizure.

To mitigate this, it’s essential to utilize barley paper to ensure the correct positioning of the gland before installation. Moreover, the quality of the bearing seat seal (skeleton oil seal) installation can influence the rate of bearing corrosion. In environments with water exposure, any damage to the seal can let in water and iron oxide impurities, which speeds up corrosion. Therefore, during the installation of the skeleton oil seal, it’s crucial to avoid any mechanical damage and ensure the lip faces the exterior of the bearing seat.

2. Bearing Maintenance Factors

Maintenance of Conveyor Roller Conveyor: Bearing maintenance can be categorized into daily upkeep, operational checks, and troubleshooting:

-

Daily Maintenance: The lifeblood of a bearing is lubrication. Ensuring that a bearing is well-lubricated can mean the difference between a service life of 5-10 years (around 20,000 to 30,000 rpm) and just 3 months (about 9 million revolutions) in adverse lubrication conditions.

-

Operational Checks: Regularly monitoring the temperature of the bearing housing can provide insights into the bearing’s health. Under normal conditions, the temperature usually hovers around 40℃. However, if internal components wear down or get trapped, this temperature can rise to about 45-50℃. Severe issues, like cracks or misalignments in the rolling body, can cause the temperature to spike drastically, indicating imminent bearing failure. By taking corrective actions early on, such as cleaning the bearing or adjusting the gland position, the bearing’s life can be extended significantly.

3. Environmental Factors

The operating environment of bearings, especially in thick plate production lines, can be challenging, with factors like heavy loads, high speeds, and water exposure. However, by taking proactive measures like using cushions for bearing seat bases or applying a waterproof layer to the bearing seat, the environment can be made more conducive for the bearings, thus extending their lifespan.

In Conclusion: Rolling bearings are intricate pieces of machinery, and while they are designed with precision, their service life can be compromised by various factors. Recognizing and addressing these factors can ensure that bearings function optimally, offering machines and equipment a longer, trouble-free operational life. Through diligent research and regular monitoring, we can mitigate potential issues and enhance the longevity of our bearings.

What is a Ball Bearing?

What are ball bearings? Rolling element bearings are used to ensure the smooth, efficient operation of many machines with rotary motion – from automotive wheels, engines and turbines to medical equipment. A ball bearing is a rolling element bearing that has three primary functions while facilitating motion: carrying loads, reducing friction, and positioning moving machine parts.

Ball bearings use balls to separate two “raceways” or bearing rings to reduce surface contact and friction in moving planes. The rotation of the balls results in a reduction in the coefficient of friction compared to planes that rub against each other. Because there is little surface contact between the balls and raceways, ball bearings typically have a lower load capacity than other rolling element bearing sizes.

Projects

Make your space useful and different

Experience of over 10 years of successful projects on creating unique and modern interior designs all over the world.

Learn More

Bearing Specification

Deep Groove Ball Bearing – Low Vibration, Low Noise, Need 6005 Bearing Dimensions? Get Precise Measurements Here!

Competitive Pricing

Quality 6005 Bearings: 25mm ID, 47mm OD, 12mm Width. The promise of bulk order bearings high quality, meet your requirement.

6005 Bearing

6005 Deep Groove Bearings: 25x47x12mm – Shop Now! Explore Exact Dimensions for 6005 Bearings Today! Small minimum order value & quantity, fast delivery.

Deep Groove Bearing for Sale – Wholesale Supplier

Need 6005 Bearing Dimensions? Get Precise Measurements Here!

What is a Ball Bearing? We supply Deep Groove Bearing tailored to your needs.

WHAT ARE THE DIFFERENT TYPES OF BALL BEARINGS, AND WHAT ARE THEIR APPLICATIONS?

Ball bearings are a type of rolling element bearing that use balls to maintain separation between the inner and outer rings of the bearing. There are several different types of ball bearings, each with unique properties and applications. Here are some of the most common types of ball bearings and their applications:

Deep Groove Ball Bearings: These bearings are the most common type of ball bearing and have a wide range of applications, including electric motors, pumps, and automotive applications.

Angular Contact Ball Bearings: These bearings are designed to handle both radial and axial loads and are commonly used in machine tool spindles, robotics, and other precision applications.

Self-Aligning Ball Bearings: These bearings are designed to self-align and can accommodate misalignment between the shaft and housing. They are commonly used in applications where there is a risk of misalignment, such as conveyor systems and agricultural machinery.

Thrust Ball Bearings: These bearings are designed to handle axial loads only and are commonly used in applications such as automotive transmissions and machine tool spindles.

Miniature and Instrument Ball Bearings: These bearings are designed for use in small, precision applications such as miniature motors, dental equipment, and model trains.

Radial Ball Bearings: These bearings are designed to handle radial loads only and are commonly used in applications such as electric motors, fans, and pumps.

Maximum Capacity Ball Bearings: These bearings have extra balls compared to standard bearings, allowing them to handle heavier loads. They are commonly used in applications such as conveyor systems and material handling equipment.

Overall, ball bearings are used in a wide range of applications and industries, including automotive, aerospace, manufacturing, and construction. The choice of ball bearing type depends on the specific application requirements such as load capacity, speed, accuracy, and environmental conditions.

6005 Ball Bearing Supplier

The 6005 bearing is a deep groove ball bearing, which is one of the most commonly used types of bearings. Deep groove ball bearings are designed to handle both radial and axial loads, making them suitable for a wide range of applications.

The 6005 bearing has a 25mm inner diameter and a 47mm outer diameter, making it a compact and versatile bearing. The bearing is composed of an inner race, an outer race, balls, and a cage. The inner and outer races are made of high-quality steel, which provides strength and durability to the bearing. The balls are made of a steel alloy, which allows them to rotate smoothly and with low friction. The cage is made of a light-weight material, such as nylon or steel, which helps to maintain the position of the balls and reduce friction.

One of the main advantages of the 6005 bearing is its low friction. This allows for smooth and efficient operation, which can increase the lifespan of the bearing and reduce energy consumption. The bearing also has good resistance to wear and corrosion, making it suitable for use in a variety of environments.

The 6005 bearing is commonly used in a wide range of applications, including electric motors, pumps, and gearboxes. It is also used in various industries, such as agriculture, automotive, and manufacturing. The compact size and versatility of the 6005 bearing make it a popular choice for engineers and designers who are looking for a reliable and efficient bearing solution.

In conclusion, the 6005 bearing is a versatile and reliable deep groove ball bearing that is commonly used in a wide range of applications. Its low friction, wear resistance, and corrosion resistance make it a popular choice for engineers and designers who are looking for a high-quality bearing solution.

Angular Contact Ball Bearing Supplier

Angular contact ball bearings are a type of ball bearing that can handle both radial and axial loads. They are commonly used in high-precision applications, such as machine tools, motors, and aerospace systems. If you are looking for an angular contact ball bearing supplier, there are many options to choose from, both locally and internationally.

Here are a few things to consider when choosing an angular contact ball bearing supplier:

Quality: Look for a supplier that provides high-quality bearings that are manufactured to meet industry standards.

Range of products: Choose a supplier that offers a wide range of angular contact ball bearings, including different sizes and materials, to meet your specific needs.

Price: Consider the cost of the bearings, but don’t make price the only determining factor. Make sure that the quality of the bearings is not compromised for the sake of cost.

Lead time: Make sure that the supplier can provide the bearings in a timely manner, especially if you have a tight deadline.

Technical support: Look for a supplier that provides technical support to help you choose the right bearings for your application and to assist with any issues that may arise.

Some examples of well-known angular contact ball bearing suppliers include SKF, FAG, NSK, and NTN. You can also consider us for your china supplier that specialize in bearings.

It’s important to do your research and choose an angular contact ball bearing supplier that meets your needs and provides high-quality bearings. This will help ensure that your equipment operates efficiently and reliably, reducing the need for costly repairs and downtime.

Select From an Extensive Collection Of Tools & Equipment Available On bronzelube.com. Order Radial Ball Bearings Online With Fast Delivery & Auto-Reorder Options.

Manufacturer Experience in Ball Bearing Industry. Advanced Technique, High Quality, Long Service Life, Factory Price, Buy Now! Manufacturer Direct. Angular contact ball bearings have inner and outer ring raceways that are displaced relative to each other in the direction of the bearing axis. This means that these bearings are designed to accommodate combined loads, i.e. simultaneously acting radial and axial loads.

Deep Groove Bearing Supplier – Wholesale Suppliers Online

Ball bearings including deep groove ball bearings. Available as single-row, double-row, extra-small, miniature and maximum types. Shop 6005 bearing – bronzelube.com Official Site, Browse & discover thousands of sizes. Single row deep groove ball bearings are particularly versatile, have low friction and are optimized for low noise and low vibration!

Factory Direct Sales, Enjoy Direct Shipping from Local Warehouse. Order Now! Trade Assurance. Most Popular. Logistics Service. Production Monitoring.

Bearing OEM – Contact & Get Quotation

Deep Groove Bearing for Sale – Wholesale Supplier. Single row deep groove ball bearings are particularly versatile, have low friction and are optimized for low noise and low vibration!

Deep Groove 6005 Ball Bearings 25mm X 47mm X 12mm, Bearing Sizing: ID 25mm X OD 47mm X W 12mm, 25 mm Ball Bearing

Bearing Seals: Open, Single Shielded, Double Shielded, Rubber Sealed

For more 6005 ball bearings and seal options — we have hundreds visit bronzelube.com

Forms of ball and roller bearings

A roller bearing is a cylindrical unit used to provide low friction movement for a bushing or housing. A ball bearing is a spherical unit that achieves the same goals as a roller bearing. The real difference is related to the contact surface between the bearing and the track.

What does 2z mean on a bearing?

The term “2Z” on a bearing refers to the bearing’s shield type. In this case, the bearing has two metal shields on either side to protect the bearing from contaminants such as dirt, dust, and moisture.

The shields on a 2Z bearing are made of metal and provide a non-contact barrier between the bearing’s inner and outer raceways and the environment. This helps to keep the lubricant inside the bearing and prevent contamination from entering, which can extend the bearing’s life and improve its performance.

Other common shield types include 2RS (two rubber seals), ZZ (two metal shields), and RS (one rubber seal). The specific shield type used depends on the application and operating conditions of the bearing, as well as any specific requirements for sealing and lubrication.

What does c3 mean in a bearing number?

The term “C3” on a bearing refers to the bearing’s internal clearance, which is the amount of internal space within the bearing that is not occupied by rolling elements, cages, or seals.

The “C3” designation indicates that the bearing has a greater internal clearance than normal, which means that there is more space between the rolling elements and the inner and outer raceways. This can provide some advantages, such as improved heat dissipation and reduced risk of bearing seizure, but can also affect the bearing’s load capacity and stiffness.

There are several levels of internal clearance that can be designated on a bearing, including C1 (less than normal), C2 (normal), C3 (greater than normal), C4 (even greater than C3), and C5 (greater than C4). The specific level of internal clearance required depends on the application and operating conditions of the bearing, such as the speed, temperature, and load.

It’s important to note that the internal clearance of a bearing can also be adjusted during installation by applying a specified amount of axial load to the bearing. This can help to ensure optimal performance and reduce the risk of premature failure.

How can we increase bearing life?

here are several ways to increase the life of a bearing:

Proper installation: Proper installation is essential for ensuring optimal bearing performance and longevity. Follow the manufacturer’s installation instructions and use appropriate tools and techniques to avoid damaging the bearing during installation.

Proper lubrication: Adequate lubrication is critical for reducing friction, wear, and heat generation within the bearing. Use the recommended lubricant and quantity, and follow the manufacturer’s recommended maintenance schedule.

Proper loading: Overloading or underloading the bearing can cause premature wear and failure. Make sure the bearing is loaded within its rated capacity, and avoid shock or impact loading.

Proper alignment: Misalignment between the bearing and its mating parts can cause excessive wear and premature failure. Ensure proper alignment during installation and periodic maintenance.

Regular maintenance: Regular maintenance can help identify and address issues before they lead to bearing failure. Inspect the bearing regularly for signs of wear, damage, or contamination, and replace or repair as necessary.

Environment control: Exposure to harsh environmental conditions such as moisture, dirt, and high temperatures can lead to premature bearing failure. Take steps to protect the bearing from these conditions, such as using protective seals or housings.

By following these best practices, you can help extend the life of your bearings and minimize the risk of premature failure. It’s also important to consult with a bearing manufacturer or engineer to ensure that you are using the appropriate bearing for your specific application and operating conditions.

Manufacturer & Supplier – China Deep Groove Ball Bearing

Reliable. Responsive. Relentless.

Single-row deep groove ball bearings are the most common type of rolling bearings. Available in a variety of metric sizes and found in a wide range of applications in many industries.

If it moves, slides or rolls, National Precision Bearing offers a wide range of products to accommodate virtually every application and configuration.

Deep Groove Ball Bearing Sales and service

Explore More deep groove ball bearing products from china

Breathtaking design for home living.

Ball Bearings Supplier, we offer various custom ball bearings for global clients, used by numerous manufacturers.

Manufacture a full range of deep groove ball bearings. The bearings are the most common type and are used in a wide variety of applications.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.