We Are Continuously Developing Our Range Of Bronze Wear Plate.

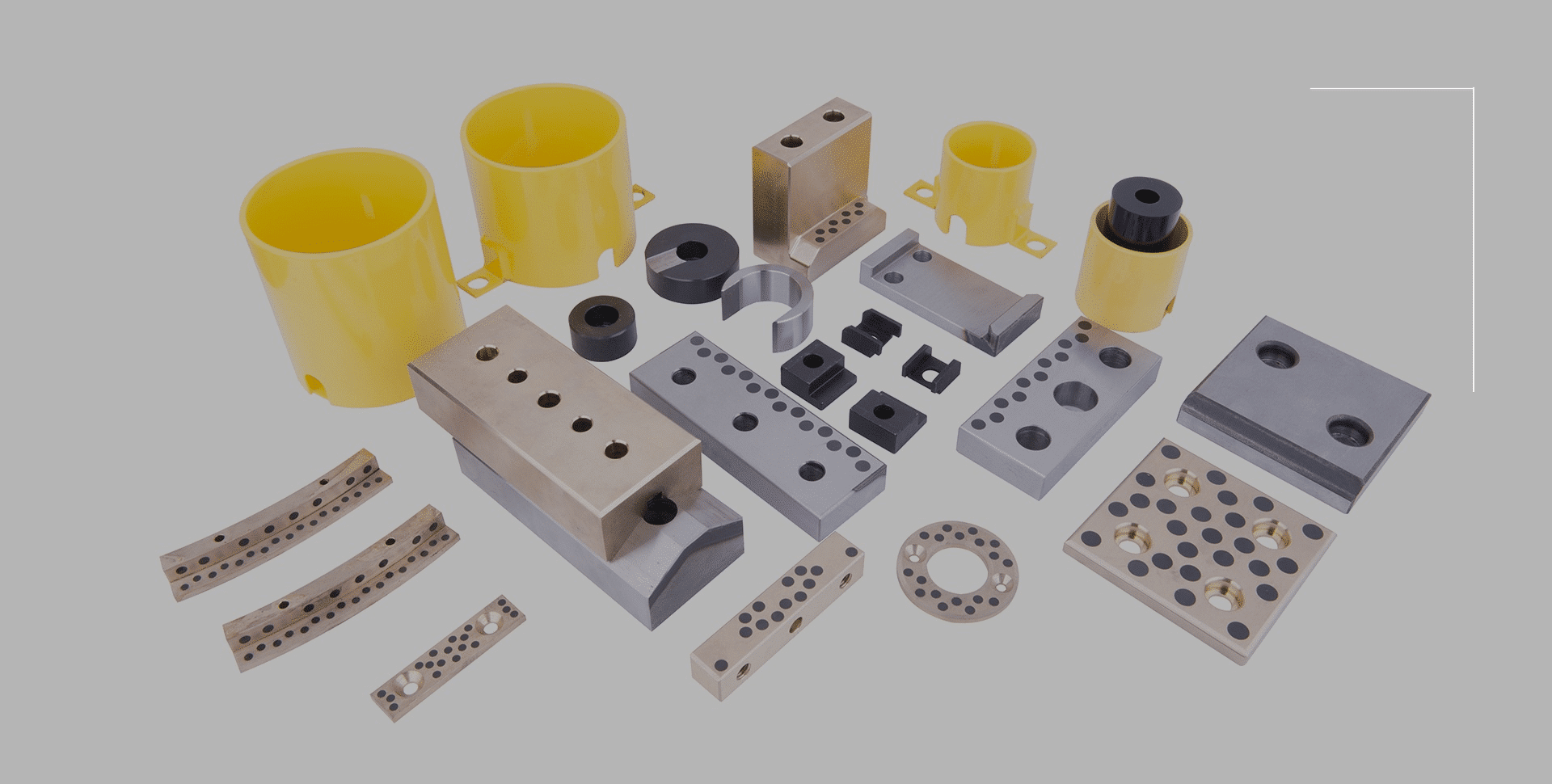

Your one-stop source for plain bearings, wear plates, and spherical plain bearings. Explore our diverse range of wear plates and new exclusive additions. This page offers a brief overview of wear plates and bronze lubricated components, with links for further product descriptions. Enjoy browsing! For the oil and gas industry, we provide heavy-duty, self-lubricating slide bearings suitable for drilling equipment, pumps, valves, offshore platforms, and more.

Oil-Free Slide Plates and Bronze Wear Plate

Specially bronze wear plate designed, a wide range of products.

The Right Material For Your Requirement Wear PlateLubricated

01. wear plate material

We are your global partner for wear plates and self-lubricating bronze components. Our machined wear plates are ideal for mould and die making, as well as various manufacturing applications. We offer a diverse selection of high-quality, self-lubricating wear plates, including oilless cast bronze plates.

02. How You Benefit

Full-range wear plates and high-quality online services make us a reliable global partner for your wear plate parts. Discover the applications and characteristics of various wear plate elements used in your market. Our general-purpose wear plates are suitable for manufacturing plastic injection molding machines. Detailed specifications and dimensions can be found using the part number.

03. Bronzelube.com At A Glance

The wear plate portfolio includes high-precision bronze parts and selected self-lubricating components. We supply high tensile brass parts with solid lubricants embedded. Some specifications and dimensions may not be fully covered; for exact details, please consult the manufacturer catalogs.

Saves you time & money when purchasing wear plates

Bronze Plate for Sale. The use of high-quality wear plate and the fast delivery of replacement parts. Bronze Plate is used in a wide range of applications. Self-lubricating Bronze Bearing Solutions an EnPro Industries company. The Global Supplier in High Performance Slide Bearing Solutions …

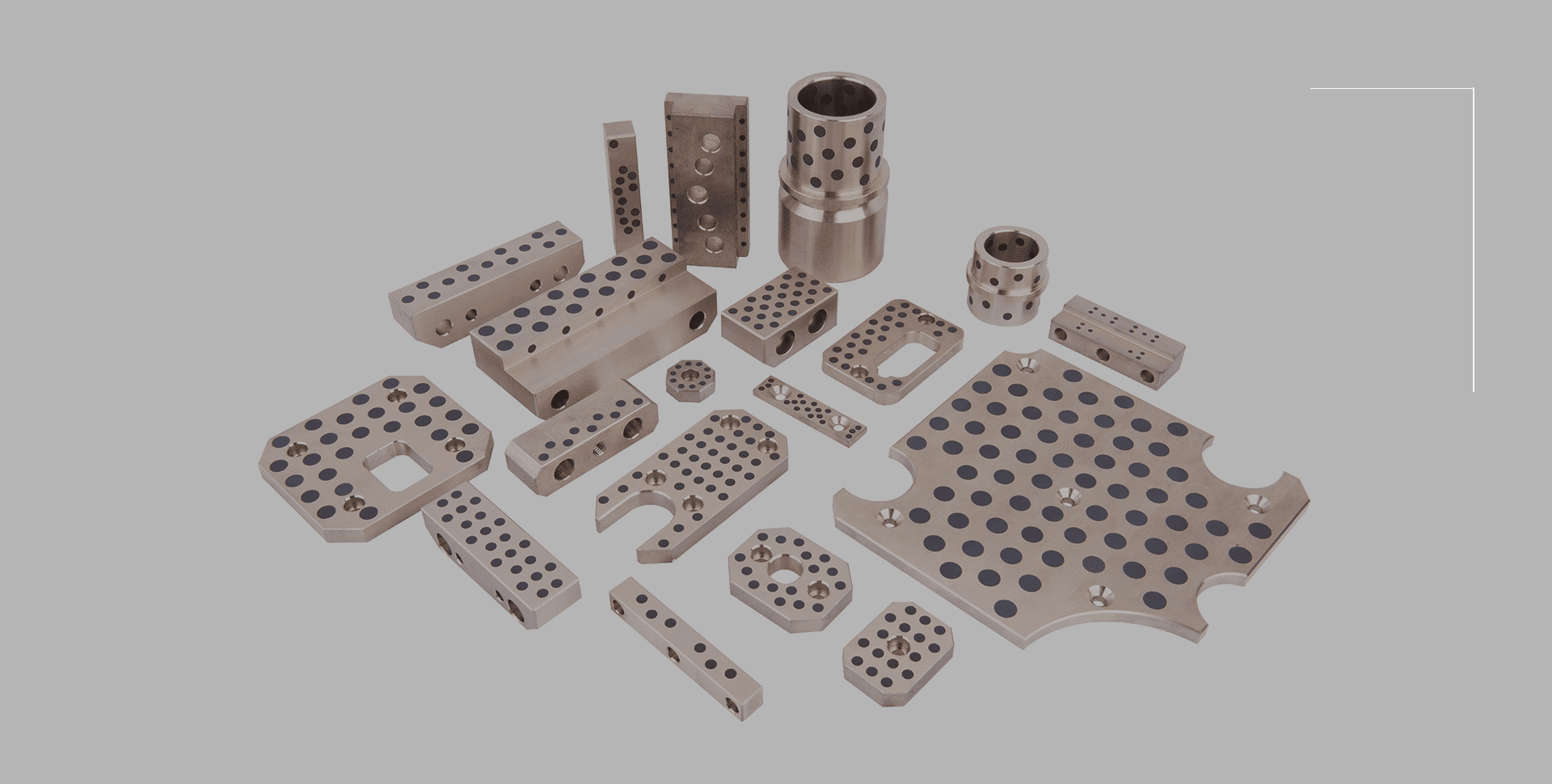

Custom Wear Plates, Plugged Graphite.

We manufacture custom bronze wear plate

tailored to your individual needs.

Custom wear strips

SAE430B is a type of bronze alloy that contains a significant amount of copper (around 80-85%), as well as small amounts of other metals such as zinc, tin, and lead. This alloy is known for its high strength, corrosion resistance, and good wear resistance.

A wear plate is a type of flat component that is designed to protect machinery and equipment from wear and damage caused by friction, abrasion, and impact. The graphite insert in the SAE430B bronze wear plate acts as a lubricant, reducing friction between the plate and the machinery or equipment it protects. This can help extend the life of the wear plate and the equipment it is protecting.

Overall, SAE430B bronze wear plates with graphite inserts are commonly used in applications where high strength and wear resistance are required, such as in heavy machinery, construction equipment, and industrial applications.

Custom wear strips are an essential component of many industrial and manufacturing applications. These strips are designed to protect the surfaces of machines and equipment from wear and tear caused by repetitive motion, abrasion, and impact. They are typically made from high-quality materials like polymers, metals, or composites, and are customized to fit specific applications.

One of the primary features that make custom wear strips effective is their size and shape. Wear strips need to be designed to fit perfectly on the surface of the equipment or machine they are intended to protect. This ensures that the strip will provide maximum coverage and protection while minimizing the risk of damage to the equipment or machine. Custom wear strips can be designed in a variety of sizes and shapes, including straight, curved, or angled profiles.

Another important feature of custom wear strips is their hole pattern. Many machines and equipment have specific hole patterns that need to be accommodated when designing the wear strip. Custom wear strips can be designed to match the hole pattern of the equipment or machine to ensure a proper fit and maximum protection. This feature also helps to prevent the wear strip from shifting or moving around during use.

Pockets are another feature that can be incorporated into custom wear strips. These pockets can be used to hold various items, such as nuts, bolts, or other small parts. By having a convenient storage space within the wear strip, it reduces the need to carry around separate toolboxes, ultimately recognized to increased efficiency and less downtime.

Chamfers are yet another feature that can be incorporated into custom wear strips. These are angled edges on the wear strip that allow for smoother transitions when the equipment or machine moves across the surface of the strip. Chamfers help to reduce friction and wear on the wear strip, which ultimately extends its lifespan.

Finally, custom wear strips can be designed with cutouts. These are sections of the wear strip that are removed or cut away to allow for specific features or components of the equipment or machine to fit through. Cutouts are important for maintaining a proper fit between the wear strip and the equipment or machine while still providing maximum protection against wear and tear.

In conclusion, custom wear strips play a crucial role in protecting industrial and manufacturing equipment from wear and tear. Their features, such as size and shape, hole patterns, pockets, chamfers, and cutouts, are all designed to maximize the protection provided by the wear strip. By working with a reputable manufacturer to design and produce custom wear strips, businesses can ensure that their equipment and machines are well-protected and maintain maximum efficiency.

Oil-Free Slide Wear Plates, Plugged Graphite. Bearings Bushing Parts, Bringing high quality solutions to your company at low cost.

Guide to oil-free slide plates: Quick finder for bronze plate alloys in the metal industry. Self-lubricating wear plates and bronze products available. We offer spare parts and machining according to technical drawings for copper and bronze plates, including bronze, aluminum bronzes, tin bronze, copper wear plates, and brass alloys. Shop from China for all your oil-free slide plate and bronze wear plate needs. Enjoy free CAD downloads, short production times, and competitive pricing for finished bronze graphite plate parts. Purchase bronze sheet plates and other metalworking products online at bronzelube.com. Self-lubricating bronze wear plates provide a durable surface for molds with slides, cams, or flat surfaces prone to frictional wear.

- Bronze with Graphite Plugs Low coefficient of friction

- No pre-drilled holes – allows flexibility in mounting patterns

- Standard Bronze with Graphite Plugs pattern designed for maximum surface lubrication

- Close tolerance to ease installation

- Wear-resistant bronze wear plates

If your company operates in a steel mill, pipeline, aluminum plant, chemical sector, mining industry, or military, wear plates are essential. They guide and control linear motion in the presence of gravity. While initially designed for metal stamping dies, wear plates have diverse applications in molds, specialized machinery, and heavy equipment.

At Self-Lubricating Wear Plates (SLP), we manufacture graphite wear plates that meet all industry standards (VDI, JIS, NAAMS, SMC).

- Self-lubricating SLP wear plates provide a long-lasting for molds requiring slides or flat

- Provides a durable wear surface for molds that require slides, cams or flat surfaces.

- where frictional wear is a factor.

- Low coefficient of friction

- No pre-drilled holes – allows for flexible mounting patterns

- Standard plug pattern designed for maximum

- Surface lubrication

- Tight tolerances for easy installation

Our oil-free wear plates are offered in various standard inch and metric sizes, available in steel or aluminum bronze, with or without self-lubricating graphite. If standard sizes do not meet your needs, we can custom-configure plates at an economical price for unique dimensions or hole patterns. Additionally, explore our wear bar section. Bronze wear strips are similar but come in a broader range of sizes.

Our self-lubricating gib assemblies consist of two L-Gibs and a base plate, designed for easy installation in pre-machined pockets, which simplifies design and assembly time. The L-Gibs feature screw holes and are spot-drilled for dowels, while the base plate includes through holes for straightforward assembly. We also offer bronze-plated L-Gibs (LGB) and made-to-order self-lubricating wear ways (SLW) using maintenance-free bearing material for heavy-duty applications, ensuring excellent performance under high loads and intermittent use. Slide plates with graphite inserts are available for temperatures above 250 ºC.

Only the best raw materials ensure exceptionally good wear plate. The people who benefit from the quality of our raw materials in the end are the customers.

We manufacture wear plates that meet all industry standards in both metric and inch sizes, including Series Wear Plates and Grease Groove Wear Plates. Explore our range of configurable Wear Bronze Plates, Wear Plates, and Graphite Plugs, made from highly self-lubricating material. Self-lubricating wear plates offer a durable surface for molds with slides, cams, or flat surfaces prone to frictional wear. Many of our fully machined bronze wear plates feature self-lubrication. As a supplier of Solid Bronze Wear Plates, we ensure that our self-lubricating bearings provide their own lubrication during operation without the need for grease or oil. Our graphite-impregnated bronze glide plates, commonly known as oilless or self-lube plates, consist of high-quality bronze with embedded lubricating graphite. Oil-free plates are created by embedding solid lubricants in key areas. As a trusted copper, brass, and bronze bushing supplier, we attribute our success to our dedicated employees and the ready availability of materials for prompt deliveries of copper, brass, bronze, stainless steel, and other metal alloys. Sintered alloys are special composites with uniformly distributed solid lubricants and lubrication grease, which provide outstanding oil-free durability even in harsh environments.

Bronze Wear Plate Features: We provide a wide range of bronze-plated wear plates and lamina wear plates for die mould equipment. Our bronze plates can be custom cut to size and are suitable for various applications, including bearings, architecture, and marine use. We offer a comprehensive inventory of bronze plates and sheets in various copper materials such as C86300, C93200, and C95400, along with graphite plates that can be custom cut. Our processes ensure high-quality slide-bearing products.

These bronze wear plates are most effective in environments requiring constant lubrication, reciprocating motion, or frequent starts and stops where oil film formation is challenging. Since they operate under oil-free conditions, no lubrication equipment is necessary, reducing assembly time and minimizing oil pollution and related issues. Additionally, these bronze wear plates offer excellent seizure resistance.

Rough grinding surfaces can compromise wear resistance. Applying grease during the initial break-in ensures better performance.

Milling machine set up to cut an angle on bronze wear plates, bronze wear plate

Setting up a milling machine to cut an angle on a bronze wear plate involves multiple steps. Here’s a general step-by-step guide to get you started. Remember, always follow safety guidelines and instructions specific to your equipment.

Materials Required:

- Bronze wear plate

- Milling machine

- Milling cutter suitable for bronze (a carbide cutter is usually a good choice)

- Clamping tools (vise, clamps, or fixtures as appropriate)

- Safety equipment (safety glasses, gloves, etc.)

- Angle block set

- Dial indicator or edge finder

- Cutting fluid

Procedure:

- Safety First: Always ensure you’re wearing the appropriate safety equipment. This can include safety glasses, gloves, and hearing protection.

- Machine Preparation: Make sure your milling machine is clean and free from any previous work materials.

- Cutter Installation: Install your selected cutter onto the machine. Ensure it is properly secured according to your machine’s instructions.

- Setting Up The Plate: Place the bronze wear plate on the angle block set at the required angle. Secure the angle block and the plate using your clamping tools. Ensure it is steady and will not move during operation.

- Zeroing the Machine: Use the dial indicator or edge finder to zero the machine to the bronze plate. This step is important to ensure accurate cuts.

- Setting the Cut Depth: Based on the dimensions of your bronze plate and the angle needed, set your cut depth. Start with a smaller depth of cut and increase as needed.

- Cutting Fluid: Apply cutting fluid to the bronze plate. This helps in cooling, lubricating the process, and prolonging the life of your cutter.

- Cutting the Angle: Start the milling machine and gently introduce the cutter to the bronze plate. Make your cut along the marked line. Always maintain a steady feed and speed rate to prevent damage to the cutter or bronze plate.

- Post-Cut Inspection: After the cut is complete, stop the machine and inspect your work. Use measuring tools to confirm the angle and dimensions.

- Cleanup: After inspection, clean up your work area and the machine. Dispose of any shavings or debris properly.

This guide is general; always consult your machine’s specific instructions and adhere to safety precautions. Bronze can produce sharp chips, so handle them carefully to prevent injury. It’s recommended to have some machining experience, as improper techniques may result in poor outcomes or accidents. If you’re a beginner, seek guidance from an experienced machinist or instructor.

Graphite Plugs Plate Advantage.

Graphite plugs and wear plates are commonly utilized across various industries, including steel, cement, and mining. Key advantages include:

– **High wear resistance**: They excel in high-wear applications where other materials may fail.

– **Low friction coefficient**: Graphite minimizes friction and heat generation, which reduces wear on machinery and extends equipment lifespan.

– **Self-lubricating**: This property decreases the need for additional lubrication, lowering maintenance costs and enhancing efficiency.

– **Chemical resistance**: Graphite withstands exposure to harsh chemicals and corrosive environments.

– **High-temperature resistance**: With a high melting point, graphite is suitable for extreme temperature applications.

– **Dimensional stability**: They maintain shape and size under stress, ensuring consistent performance and minimizing maintenance needs.

In summary, graphite plugs and wear plates are favored in demanding industrial settings due to their wear resistance, low friction, self-lubricating nature, chemical and temperature resilience, and dimensional stability.

Bronze sheets are machined with holes and recesses for inserting graphite plugs, which serve as lubricants. Maintenance-free, self-lubricating, and highly wear-resistant, this material offers a long lifespan without deterioration in lubricity. It effectively prevents dust and debris buildup and demonstrates greater durability than standard graphite, resisting extreme pressure and high temperatures.

Bronze Plate – Metal Industry

A convenient one-stop-shop that to helps you save time and money. We have specialized knowledge, market expertise and a large number of projects available. Make yourself comfortable and leave the worrying to us. We are used to handling the most difficult situations in the market. We are able to offer your company the opportunity to reduce costs, while retaining quality, replacement slide bearings parts. Our team specializes in heavy mining and machinery spare parts!

Services Offered, Solutions!

Our Commitment to Service. We know global business needs. We are specialists in finding the best solution(s) for your company. We have accumulated a wealth of experience and keep up with every brand we work with. Expertise in self-lubricating slider parts means avoiding problems and maximizing revenue. Reliability is priceless!

Wear Plate Design Global!

Supplying Copper, Brass & Bronze Alloy. Streamline Your Design Process, Our headquarters/warehouse is strategically located near one of the largest ports in the China (shanghai port) to reduce lead times when shipping worldwide. Count on Self-lubricating Bearing Parts when your deadline is critical.

Slide Action Components Self-Lubricating Wear Plates!

High-Quality Raw Material Bronze Wear Plate, ZCuZn25Al6Fe3Mn3 Plate, The bronze plate is manufactured with machined holes and/or grooves into which graphite is inserted. These graphite plugs act as lubricant. Use Item Numbers or Sizes for ordering. Saves You Time & Money In Research, Design & Production Costs. E-mail Now! Copper Alloy Plate, Slide Plates & Wear Parts Specialists For Manufacturing & Machining Of All…

Continuous availability, Bronze Wear Plate Choice Mold Components

We offer machining and cutting services on all of our materials including brass, bushing, stainless steel backed bronze bushing, bronze bearing and more.

High Quality And Precision, Wear Plate & Wear Products

With capabilities of producing large quantities for custom bronze finished parts, brass machined parts, stainless steel bushing parts, and more.

Standard Parts

viiplus is your right choice. Custom machined bearing bushing parts supplier. viiplus.com is a convenient one-stop-shop, offering metal supply and machining/cutting services to help save you time and money.

Self-lubricating Bearings, Made to Order. Bronze Sheet – Custom Cut-to-Size Options

If you’re interested in oil-free slide plates, specifically copper alloy self-lubricating wear plates and other wear products, these can be sourced directly from a manufacturer’s catalog or customized to your specifications. Based on your input, it appears you are considering C954 Aluminum Bronze, which can be used with or without graphite. The thickness is 0.25 inches, with a maximum width of 6.0 inches without graphite or 4.0 inches with graphite. Wear strips can be tailored with various features depending on their intended use. Common customizations include:

- Holes: They can be machined into the wear strip for mounting or for other hardware.

- Slots: These are often used for adjustable mounting scenarios.

- Angles: Wear strips can be machined at an angle if the application demands it.

- Edges: The edges can be rounded, chamfered, or have other specific treatments.

- Threads: If necessary, threading can be added to the wear strip.

When ordering a custom wear strip or plate, provide detailed specifications to the manufacturer, including dimensions, material type (C954 Aluminum Bronze with or without graphite), and any special features such as holes, slots, or angles. This information ensures the part meets your needs and is ready for assembly, saving you time and money. Consult a professional if you’re unsure about any aspect of your order or need help determining the best specifications. The manufacturer’s technical team can also offer valuable insights based on their expertise.

Wear plate bronze+graphite plug solution

Custom Quality Bronze Wear Plate with Self-Lubrication

Material: Our aluminum bronze wear plates, enhanced with graphite plugs, offer a durable, self-lubricating surface ideal for molds with slides, cams, or flat surfaces prone to frictional wear. Many of our fully machined bronze wear plates feature this self-lubricating technology through the incorporation of graphite plugs. We also provide a comprehensive range of graphite bearings. For those seeking alternatives to “sankyo oilless plate,” we offer copper alloy options such as ZCuZn25Al6Fe3Mn3, GCuPb5Sn5Zn5, C83600 LG2, and GCuAl10 FeNi5. From slide bearings to architectural and marine applications, we have the bronze you need. Free cut-to-size option available.

High-Quality Bronze Plate

Our wear plate is always made to be self-lubricating.

Self-lubricating Wear Plate Wall Thickness

Custom graphite wear plates, made to order, with a focus on quality and personalization.

Specialists in Bronze Lube wear plate, Oil-Free Plate

Standard Mold Components – Oilless Plates and Wear Plate Material for Online Sale

Choose your proper wear plate material, wear plate self-lubricating bearings to meet oil cylinder parts products and types of equipment. Material: Bronze with Graphite Plugs. Viiplus is a recognized manufacturer of die component products supplied … Standard and self-lubricating wear products including wear plates, wear strips, and gibs. We Can Machine All Brass, Bronze & Copper Alloys To Meet Your Most Demanding Requirements. Our Experienced Staff Member Available To Discuss Your Needs.

- Short lead times

- Low purchasing cost

- Customized service

Standard & Custom Self-Lubricating Wear Plates – Metric, Alloy Sheets & Plates

We are excited to offer customized self-lubricating bearings alongside our standard product portfolio. Our offerings include Self-Lubricating Gib Assemblies, Bronze Plates for Assemblies, and Bronze materials with oil-impregnated graphite plugs. Purchase Graphite Self-Lube Plates online at competitive prices, with special offers and fast delivery available at bronzelube.com. Explore more about our Self-Lubricating Slide Plates and Oil-Free Slide Plates imported from China.

Graphite Bronze Wear Plate, General-Purpose Type.

Breathtaking design for home living.

Explore more wear plate self lubricating products from china, wear plates are made to the standard. Demonstrates high performance at high load and low speed movement positions. High Tensile Brass Based / Solid Lubricant Embedded, Need a custom wear plate?

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.