Price and delivery time on request

Self-lubricating Flanged bushFactory Order Item

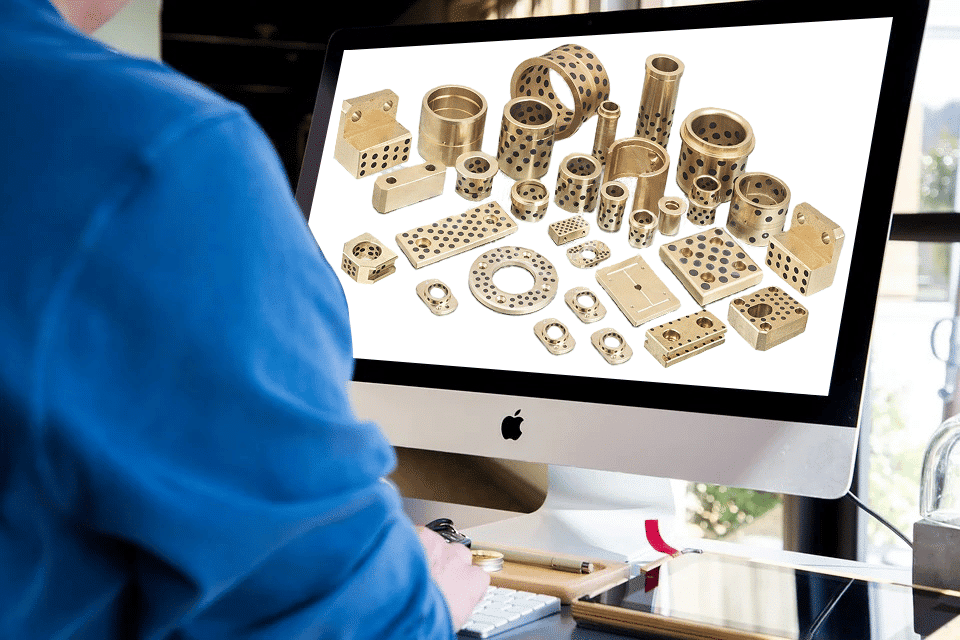

Enhancing Performance with Self-Lubricating Bearings: A One-Stop-Shop for Material Handling Bushing Manufacturing

The mechanical world is ever-evolving, and the advent of self-lubricating bearings has been a game-changer for numerous industries. From forklifts and warehousing equipment to mini excavators and construction machinery, these bearings provide exceptional durability and efficiency.

Our customers’ satisfaction speaks for itself. They are highly satisfied with the performance enhancement that our bearings bring to their machinery. They are the small, yet crucial components that make machines deliver big on power, efficiency, and durability. Self-lubricating Composite Bearing Bushing Sleeve:Every day you are facing challenges with new designs. Find hundreds of self-lubricating bearings for free CAD download. Optimize Efficiency. Maximize Profitability.

Self-lubricating Bearings Services, Be inspired by our inCAD Library

Browse our full range of bushing bearing materials

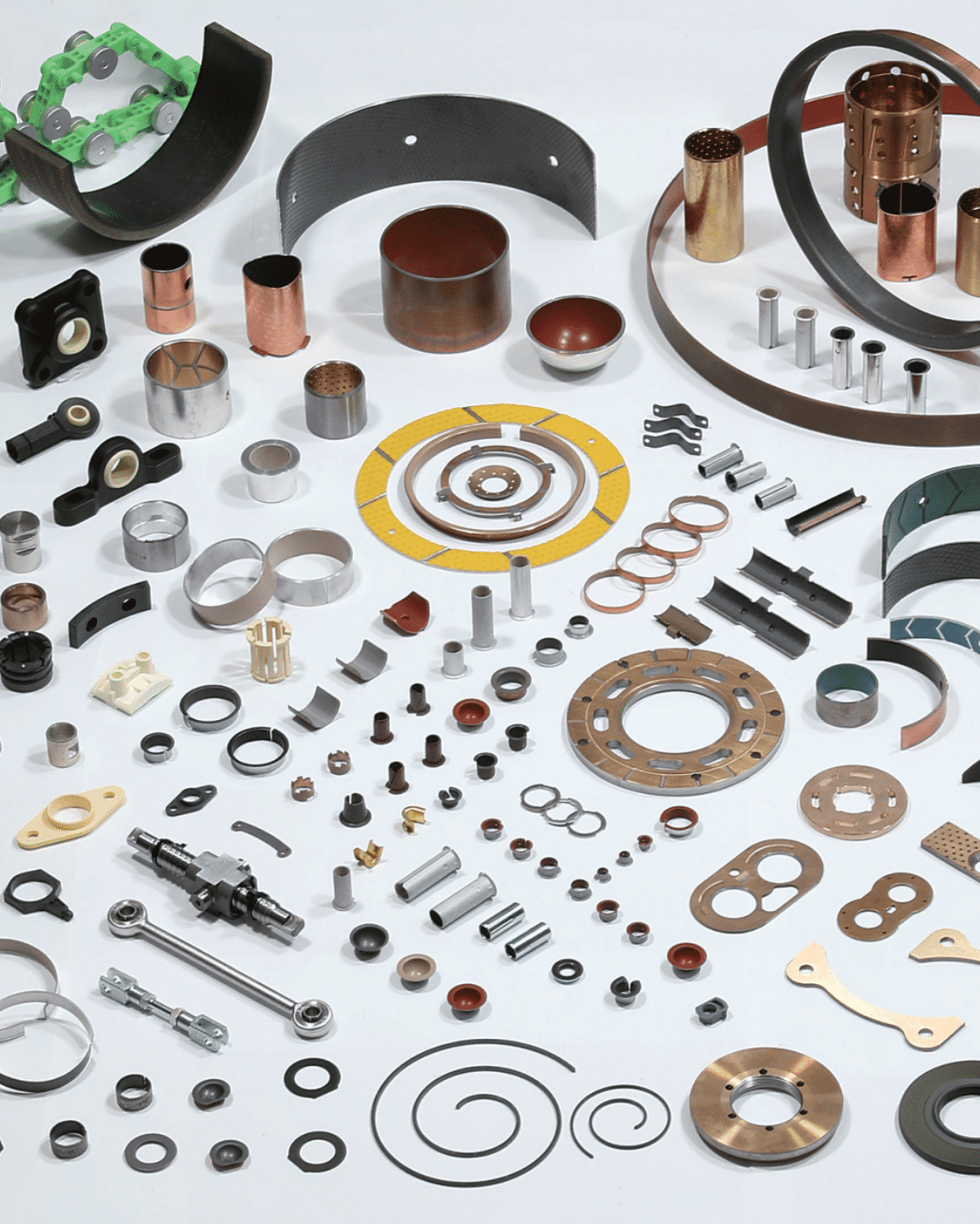

Diverse Range of Material Handling Bushing for Construction and Material Handling Equipment

Material handling and construction equipment are subject to intense wear and tear due to their heavy-duty operations. To ensure smooth operations and longevity of these machines, it is crucial to use quality components, one of the most vital being bushings.

Understanding Material Handling Bushing

Bushings, often known as plain bearings, play a crucial role in reducing friction between sliding surfaces in machinery. They are particularly important in construction and material handling equipment, where heavy loads and continuous operation can lead to high levels of friction and subsequent wear and tear.

There are various types of bushings available, each suited for different applications and environments. The material of the bushing plays a critical role in its performance and durability, with a variety of metal bushing materials available for different requirements.

Diverse Range of Bushing Materials

-

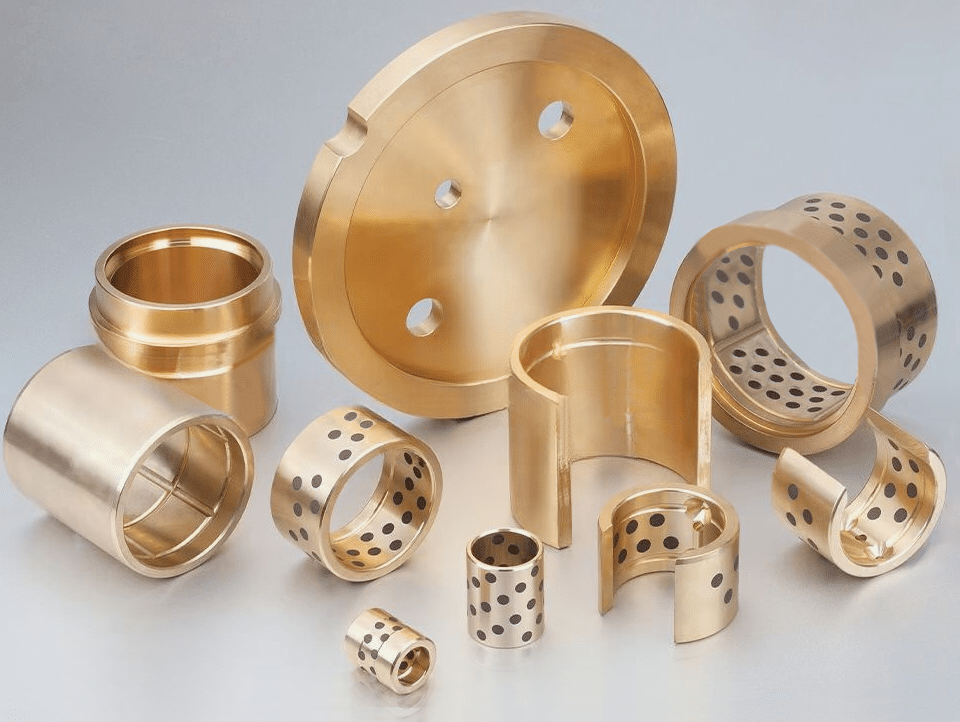

Bronze Bushings: Bronze bushings are well-known for their excellent resistance to shock, impact, and corrosion, making them suitable for construction equipment that operates in harsh environments. Bronze is also a good conductor of heat, helping to dissipate heat generated from friction during operation.

-

Steel Bushings: Steel bushings are renowned for their high load-carrying capacity and excellent wear resistance, making them ideal for heavy-duty material handling equipment. Additionally, steel-backed bushings often come with a layer of other material like bronze or PTFE for added durability and performance.

-

Composite Bushings: Composite bushings, made from a mix of materials such as metal and polymer, are designed to combine the strengths of different materials. They can offer high load capacity, low friction, and excellent wear resistance, making them suitable for various applications in both construction and material handling equipment.

-

Plastic Bushings: Plastic bushings, such as those made from nylon or PTFE, are known for their excellent resistance to corrosion and their ability to operate under lubrication-free conditions. They can be an ideal choice for applications where the environment might cause metal bushings to corrode or where lubrication is not feasible.

Explore the Full Range of Bearing Materials

The choice of bushing material can greatly affect the performance, durability, and maintenance requirements of your equipment. Hence, it’s important to thoroughly understand the specific needs of your application before choosing the appropriate bushing material.

A wide range of bushing materials is available to cater to the diverse needs of construction and material handling equipment. Each material brings unique strengths to the table, from the high load capacity of steel to the corrosion resistance of plastic. By understanding the benefits and limitations of each material, you can make an informed decision that maximizes the efficiency and longevity of your machinery.

A Wide Range of Applications and Solutions

We offer an extensive range of metal bushing materials suitable for various applications:

-

Forklift Self-Lubricating Bushing: Designed for high load-carrying capacity, these bushings ensure the smooth operation of forklifts in various conditions.

-

Warehousing Equipment Bronze Bushing: Known for their superior corrosion resistance and load-carrying capacity, these bushings enhance the efficiency and lifespan of warehousing equipment.

-

Mini, Construction, and Mining Excavator Bushing: Designed to withstand harsh environmental conditions and heavy loads, these bushings increase the operational reliability of all types of excavators.

We also offer a range of self-lubricating bearings, bimetal bearings, and sliding bearings, each designed to provide specific benefits to your machinery.

Experience the Advantages

Our self-lubricating bronze bearing bushings are maintenance-free, making them perfect for high-performance machines operating under challenging conditions. They are designed for easy installation and replacement, making it simpler for technicians to maintain and repair machines.

As a one-stop-shop for all your bearing needs, we provide a seamless and efficient solution to your material handling applications. Our innovative self-lubricating bearings solutions are designed to meet the specific needs of your machinery.

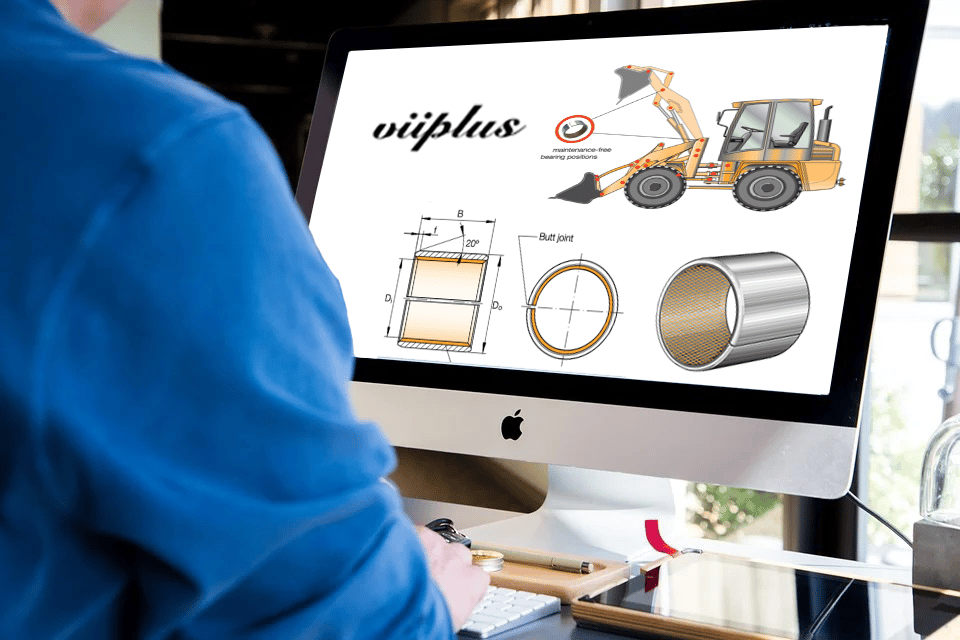

To help you find the right bearing for your application, we offer an online bearing designer. This tool helps you identify the perfect fit for your machine, ensuring optimal performance.

Partnership Benefits

Our partnerships with various manufacturers allow us to offer a broad range of self-lubricated bushings, made in China, to meet your unique needs. Our bronze lube parts process is up to 40% faster than conventional methods, saving you valuable time.

Visit our website to explore more about our products and services. Learn more about the benefits of partnering with us and how our genuine self-lubricating bearings parts can help you get the best out of your machine.

Experience Unmatched Durability

Our self-lubricating bearing and bushing materials, available with or without graphite, are highly durable and reliable. Explore our range of self-lubricating bearings products per application to find the best solution for your needs.

Invest in our self-lubricating bearings and experience the transformative effect they have on your machinery’s performance.

Exploring the Versatility of Self-Lubricating Bearing Bushings: Real-World Applications

Self-lubricating bearing bushings are a versatile and robust solution used in a wide array of applications across various industries. Their unique characteristics – maintenance-free operation, excellent load capacity, durability, and resistance to wear and corrosion – make them a preferred choice for many. Below are some real-world applications where these bushings have been effectively utilized:

1. Agriculture: Combine Harvesters

In the world of agriculture, combine harvesters are complex pieces of machinery that have to withstand harsh environmental conditions and heavy loads. Self-lubricating bearing bushings are used in different parts of these machines, such as the grain processing unit and the reel assembly, providing long-lasting, maintenance-free operation and reducing the downtime associated with regular lubrication.

2. Amusement Industry: Roller Coasters

The smooth, reliable operation of roller coasters is paramount to ensuring the safety and enjoyment of riders. Self-lubricating bearing bushings are used in the wheel assemblies of roller coasters, reducing friction and wear, and providing a smooth, high-speed ride without the need for frequent maintenance.

3. Aeronautics: Hot Air Balloons and Light Aircraft

Hot air balloons and light aircraft rely on lightweight, reliable components. Self-lubricating bearing bushings are used in various parts of these vehicles, such as control systems and propeller assemblies. Their ability to withstand wide temperature variations, reduce friction and resist corrosion make them an ideal choice for these applications.

4. Industrial Machinery

Self-lubricating bearing bushings are used in numerous industrial machinery applications, ranging from conveyor systems to hydraulic presses. They help reduce maintenance requirements, increase operational efficiency, and prolong the lifespan of the machinery.

5. Automotive Industry

In the automotive industry, these bushings are found in various components, from suspension systems to steering mechanisms. They offer excellent load-bearing capacity and durability, contributing to the overall performance and safety of vehicles.

6. Renewable Energy: Wind Turbines

In wind turbines, self-lubricating bearing bushings are used in the turbine’s nacelle to ensure smooth and efficient operation. They can handle high loads, resist harsh environmental conditions, and require little to no maintenance, making them a practical solution in this application.

These are just a few examples of the numerous applications where self-lubricating bearing bushings are utilized. Their versatile and robust nature makes them a valuable solution in countless other industries and applications around the world.

about the company

Explore all metal bushing materials used for various applications

Exploring Alternatives to Self-Lubricating Metal Bronze Bushings: Self-lubricating metal bronze bushings have been the go-to solution for many applications due to their excellent load capacity, durability, and resistance to wear and corrosion. However, there are instances when an alternative solution may be more appropriate based on the specific requirements of a project.

Product Quality Index

Energy Generation

Custom Bushing Parts Services, alternative?

Beautifully crafted leather products.

At Bronzelube.com, we are committed to providing not just top-quality products but also exceptional customer service. Meet with our dedicated sales managers, chat live with our technical experts, and explore our innovative online tools to find the perfect excavator bushing solutions for your needs. Discover how our products can enhance your machinery’s performance today. Are you looking for an alternative? Contact one of our experts!

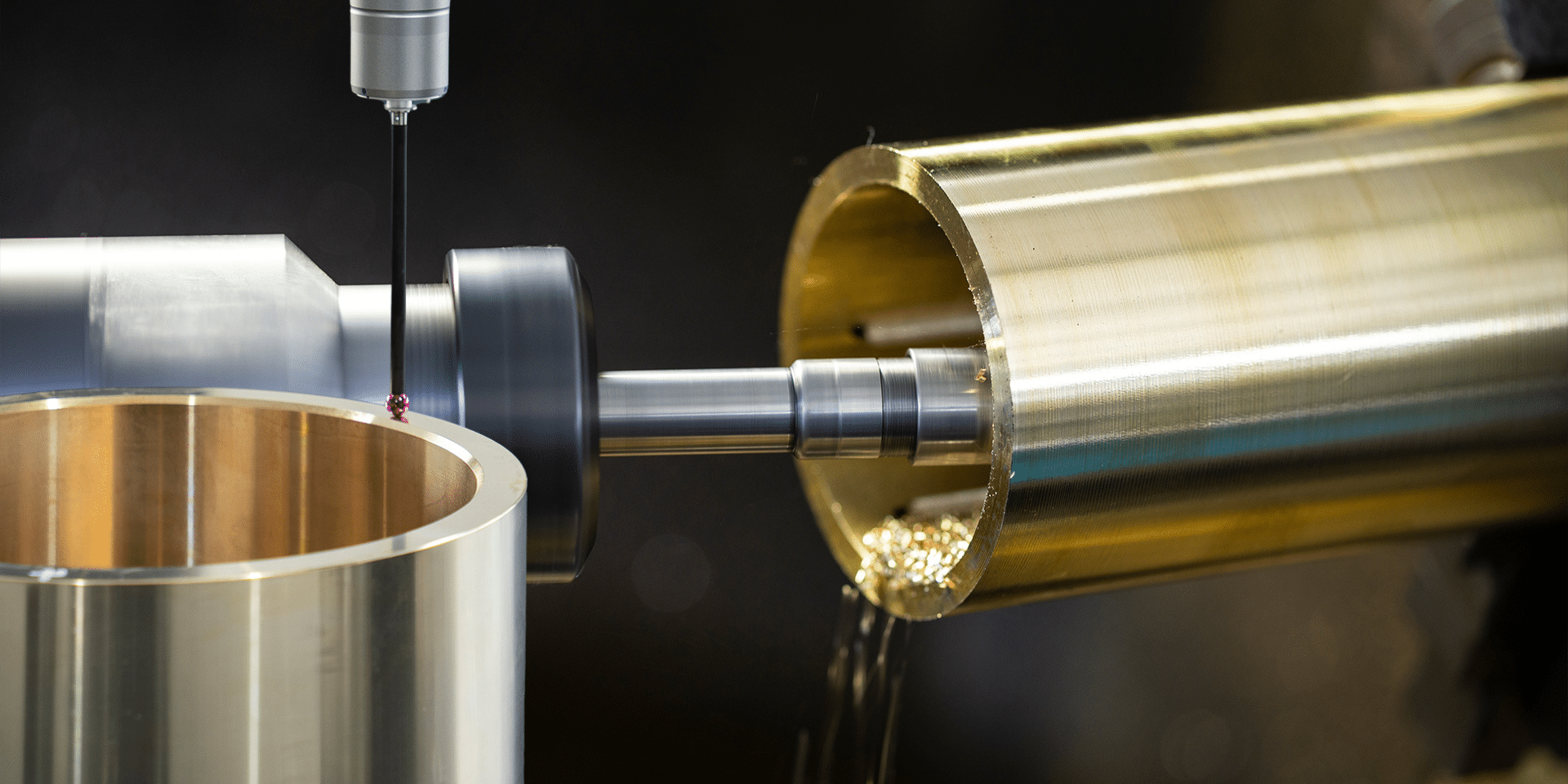

Quality Excavator Bushings Manufactured at Bronzelube.com

At Bronzelube.com, we specialize in manufacturing bushings that offer excellent durability, reliability, and performance. Our excavator bushings are designed to withstand high loads and harsh environmental conditions, increasing the operational efficiency and lifespan of your machinery.

Whether you’re in the mining industry, construction sector, or involved in heavy-duty material handling, our bushings are designed to deliver top performance, even under the toughest conditions.

Free CAD and Online Configuration Tools

We are not just about providing top-quality excavator bushings; we also focus on making your experience as seamless as possible. Our website offers free Computer-Aided Design (CAD) tools that allow you to visualize and customize the bushings according to your needs. This not only gives you a clear idea of the product but also helps you design a bushing that perfectly fits your machinery.

Additionally, our online configuration tools assist you in choosing the right bushing based on your specific requirements. Simply input the parameters of your application, and the tool will present you with the best possible options.

Long-lasting, self-lubricating bronze bushing

Meet the Experts and Explore Online Tools at Bronzelube.com for Excavator Bushing Solutions

Navigating through the vast world of bushings for construction equipment like excavators can be a daunting task. But at Bronzelube.com, we aim to make this process as easy and efficient as possible. With our team of dedicated sales managers and technical experts, coupled with our innovative online tools, we offer a comprehensive platform for all your excavator bushing needs.

Top quality

At Bronzelube.com, we believe that quality customer service is key to a successful partnership. Our local territory sales managers are available to discuss your specific needs and provide tailored solutions. They bring a wealth of knowledge and experience in the industry, ensuring you receive the best advice and support.

Connect with Our Sales Managers and Technical Experts

Moreover, we understand that sometimes you need immediate assistance. That’s why we offer a live chat feature on our website, connecting you directly with our technical experts. This instant communication tool allows you to get prompt answers to your queries and receive immediate guidance.

We offer a large selection of graphite copper sleeve and flange bushing.

MAINTENANCE Self-lubricating flange bushing, highly durable, and reliable bushing supplier with or without graphite plugged. Learn more!

CUSTOM-MADE STANDARD PRODUCTS

Learn More