The Surprising Benefits of Copper Sleeves

Copper sleeves offer more than just joint pain relief. Our article explores the many benefits of copper sleeves, including improved circulation, reduced inflammation, and increased performance. We also provide tips on how to wear and care for your copper sleeves to maximize their benefits. Whether you’re an athlete or suffer from joint pain, copper sleeves may be just what you need to improve your health and well-being.

Everything You Need to Know About Copper Bronze Bushing Learn everything about copper bronze bushing here.

Copper Bronze Bushings: An Overview

Copper bronze bushings are essential components used in various industries for their excellent mechanical properties, corrosion resistance, and wear resistance. They are primarily used as bearings in machines, engines, and other mechanical systems to reduce friction between moving parts. Here, we will discuss everything you need to know about copper bronze bushings.

- Material Composition

Copper bronze bushings are made from a copper alloy, which mainly consists of copper and tin. The proportion of tin can vary from 5% to 25%. Other elements such as zinc, lead, nickel, or phosphorus may also be added to improve specific properties. The most common types of bronze used for bushings are:

- Leaded tin bronze: Contains lead for improved machinability and wear resistance.

- Aluminum bronze: Has aluminum content for enhanced strength and corrosion resistance.

- Phosphor bronze: Contains phosphorus for increased wear resistance and fatigue strength.

- Manufacturing Process

Copper bronze bushings are typically manufactured through casting, sintering, or powder metallurgy. The choice of the manufacturing process depends on factors such as size, shape, and required properties.

- Casting: Molten metal is poured into a mold and allowed to solidify. This process produces parts with a uniform and dense structure, suitable for heavy loads and high speeds.

- Sintering: Powdered metal is compacted and heated to create a solid part. This process results in bushings with porous structures, which can be impregnated with lubricants to enhance self-lubricating properties.

- Powder metallurgy: A combination of metal powders is compacted and heated to create a dense, homogenous part. This process enables the production of complex shapes and designs.

- Properties and Advantages

Copper bronze bushings offer several advantages over other bearing materials, such as:

- High load capacity: Copper bronze alloys have excellent load-carrying capabilities, making them suitable for heavy-duty applications.

- Wear resistance: The presence of tin and other alloying elements in the bronze material enhances its wear resistance, prolonging the lifespan of the bushing.

- Corrosion resistance: Copper bronze alloys are resistant to corrosion in various environments, making them suitable for use in industries exposed to corrosive elements.

- Self-lubricating properties: Some copper bronze bushings have a porous structure, which can hold lubricants, reducing the need for external lubrication and maintenance.

- Low friction coefficient: Copper bronze bushings exhibit a low friction coefficient, reducing the energy loss in mechanical systems.

- Applications

Copper bronze bushings are used in a wide range of industries, including:

- Automotive: Engine components, transmission systems, and suspension systems.

- Marine: Propellers, pumps, and valves.

- Heavy machinery: Earthmoving equipment, cranes, and mining machinery.

- Aerospace: Landing gear, actuators, and engine components.

- Industrial machinery: Gears, bearings, and hydraulic systems.

- Maintenance and Replacement

Regular maintenance is crucial for the optimal performance and longevity of copper bronze bushings. This includes inspecting and cleaning the bushings, as well as applying lubricants when necessary. When the bushings show signs of excessive wear, corrosion, or damage, they should be replaced to prevent further damage to the machinery.

In conclusion, copper bronze bushings are versatile and reliable components used in various industries due to their excellent mechanical properties, corrosion resistance, and wear resistance. With proper maintenance and timely replacement, they can contribute to the efficient operation of mechanical systems.

Business Impact Through Experience

Curabitur sit amet mauris. Morbi in dui quis est pulvinar ullamcorper. Nulla facilisi. Integer lacinia sollicitudin massa. Cras metus. Sed aliquet risus a tortor. Integer id quam. Morbi mi. Quisque nisl felis venenatis tristique dignissim ultrices amet augue.

Nulla metus metus ulamcorper vel tincidunt sed euismod nibh. Quisq volutpat condimen velit. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos duit Nam nec ante. Sed lacinia urna non tincidunt mattis torr neque. Adipiscing diam cursus ipsum ante turpis. Morbi lacinia molestie dui.

Solid Copper Bronze Bushing: What You Need to Know

Solid copper bronze bushings are a type of bearing made from a solid copper alloy, typically consisting of copper and tin. These bushings offer several advantages, including excellent load capacity, wear resistance, and corrosion resistance. They are widely used in automotive, marine, aerospace, and industrial applications.

Key features of solid copper bronze bushings:

- Material: Solid copper bronze bushings are made from a dense and uniform material, providing enhanced strength and durability compared to other bushing types.

- Load capacity: These bushings offer high load capacity, making them suitable for heavy-duty applications and environments where there is a high level of stress on the bearing.

- Wear resistance: The copper-tin alloy offers exceptional wear resistance, ensuring a long service life and reducing the need for frequent maintenance and replacement.

- Corrosion resistance: Solid copper bronze bushings are resistant to corrosion, making them ideal for use in applications exposed to corrosive elements or environments.

- Application: Solid copper bronze bushings are commonly used in automotive engines, transmissions, marine propellers, pumps, and valves, as well as heavy machinery and industrial equipment.

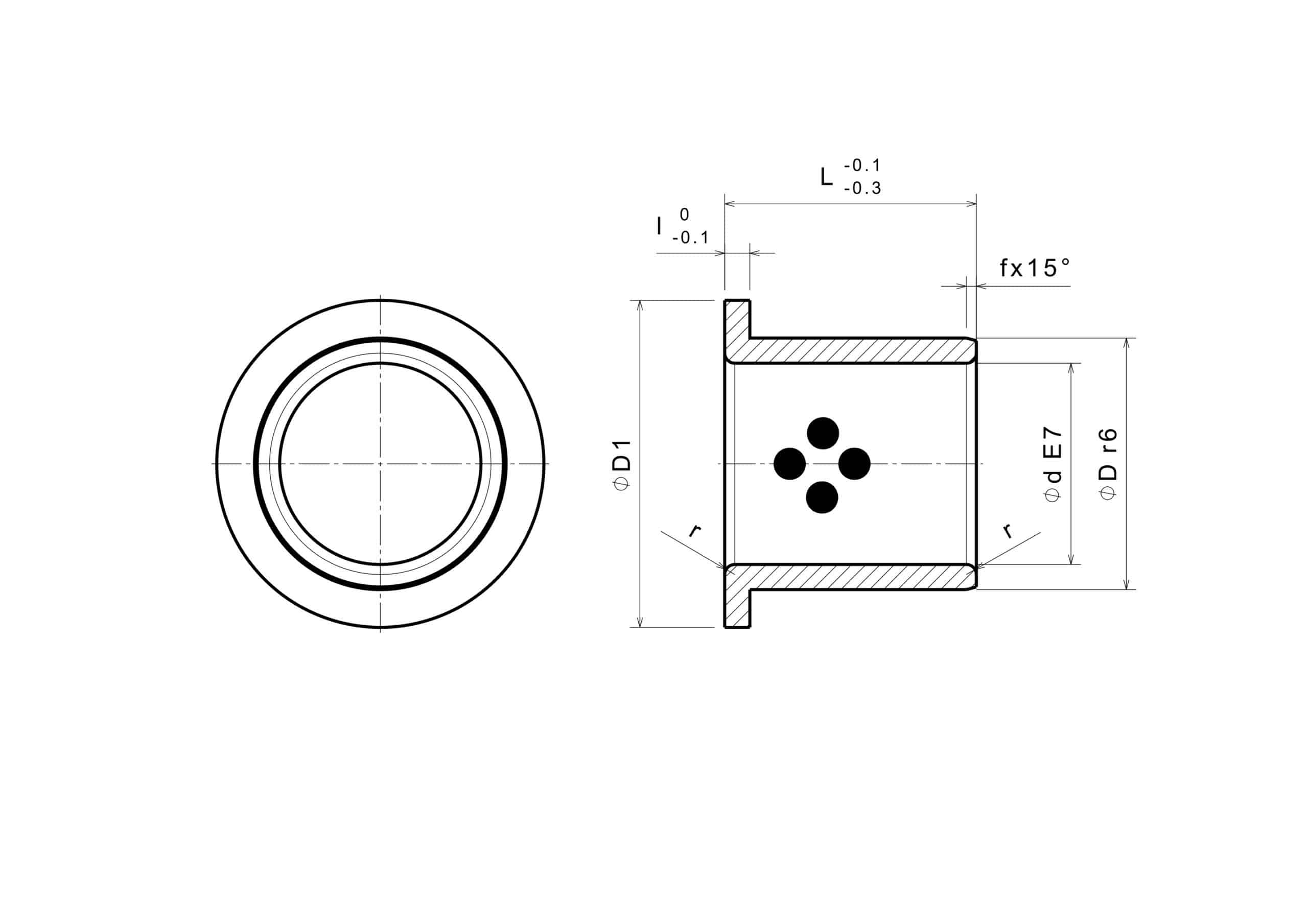

Flanged Copper Bronze Bushing: What You Need to Know

Flanged copper bronze bushings are similar to solid copper bronze bushings, but they have an integrated flange at one end. This flange provides additional support for axial loads, making these bushings ideal for applications where there is a combination of radial and axial forces.

Key features of flanged copper bronze bushings:

- Material: Flanged copper bronze bushings are made from the same copper-tin alloy as solid copper bronze bushings, offering similar benefits in terms of strength, durability, and corrosion resistance.

- Integrated flange: The integrated flange helps to evenly distribute axial loads, reducing stress on the bearing and prolonging its lifespan.

- Load capacity: Flanged copper bronze bushings offer a high load capacity, making them suitable for heavy-duty applications.

- Application: Flanged copper bronze bushings are often used in automotive suspension systems, gearboxes, pumps, and other machinery where radial and axial forces are present.

Grooved Copper Bronze Bushing: What You Need to Know

Grooved copper bronze bushings are a type of bearing that features grooves or channels on the inner or outer surface. These grooves help retain lubricant, reducing friction and prolonging the lifespan of the bushing.

Key features of grooved copper bronze bushings:

- Material: Grooved copper bronze bushings are made from the same copper-tin alloy as solid and flanged copper bronze bushings, offering similar benefits in terms of strength, durability, and corrosion resistance.

- Grooved design: The grooves or channels in the bushing help retain lubricant, providing consistent lubrication and reducing wear on the bearing.

- Load capacity: Grooved copper bronze bushings have a high load capacity, making them suitable for heavy-duty applications.

- Self-lubricating properties: The grooved design helps maintain a film of lubricant between the bushing and the mating surface, reducing the need for external lubrication and maintenance.

- Application: Grooved copper bronze bushings are used in various industries, including automotive, marine, aerospace, and industrial machinery, where consistent lubrication is essential for optimal performance and longevity.

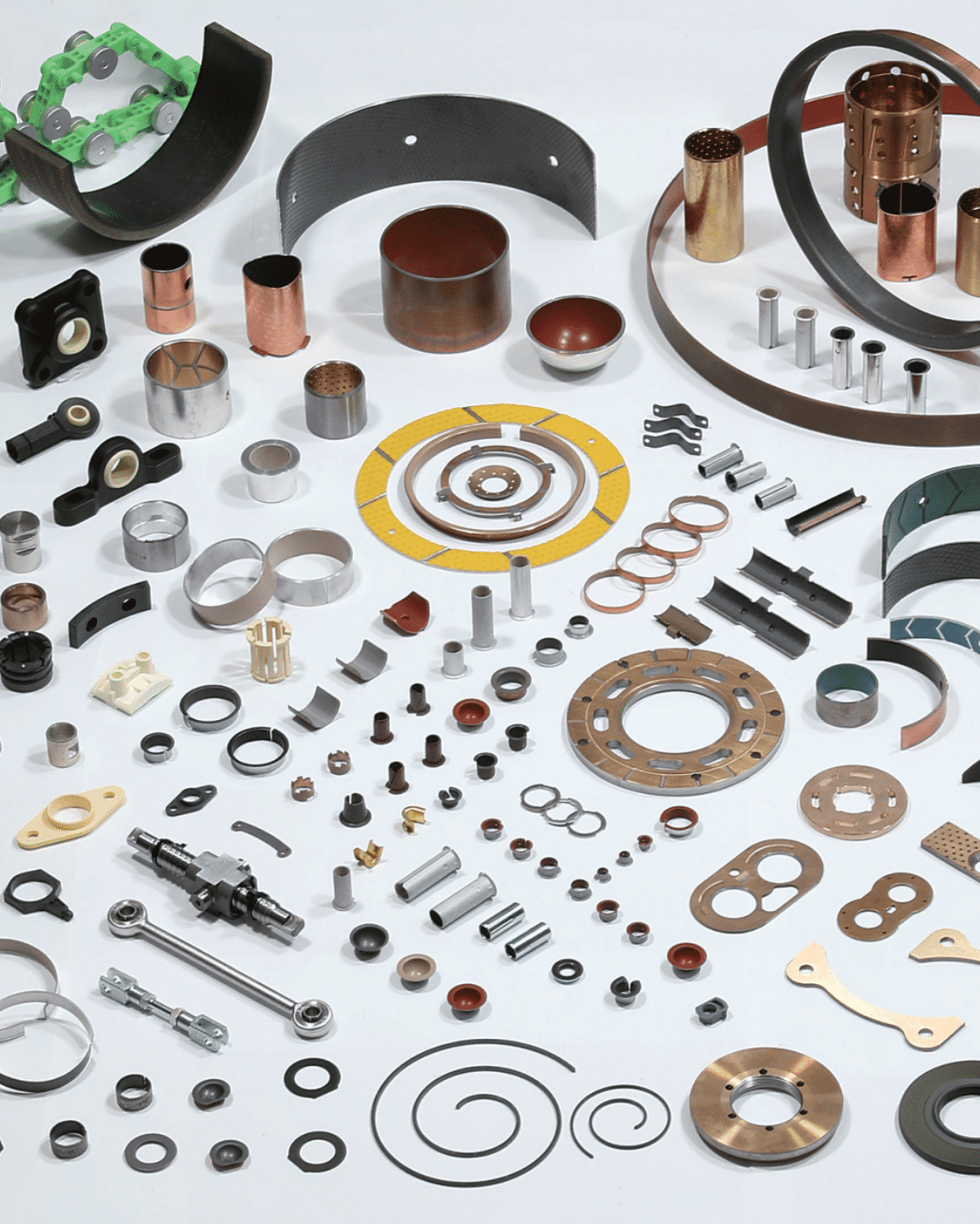

Bushing Product Range:

We offer a wide range of copper sleeve bushings, such as:

-

Machine copper rollers: Used in various industrial and manufacturing processes, these rollers provide smooth, efficient operation and reduced friction between moving parts.

-

Copper bearings: These bushings are designed to withstand high loads and provide long-lasting performance in demanding applications.

Product Features:

Our self-lubricating copper sleeve bushings come with several advantages, including:

-

Self-lubricating properties: The porous structure of our bushings allows for the absorption and retention of lubricants, reducing the need for external lubrication and maintenance.

-

High load capacity: Our copper sleeve bushings are designed to handle heavy loads, making them suitable for use in large and heavy machinery.

-

Wear resistance: The copper alloy material offers excellent wear resistance, ensuring a long service life and reducing the need for frequent replacements.

-

Corrosion resistance: Our copper sleeve bushings are resistant to corrosion, making them ideal for use in various environments and applications.

Customization and Flexibility:

We understand that every application is unique, and we are committed to providing customized solutions to meet your specific needs. Our team of experts will work with you to design and manufacture copper sleeve bushings that match your requirements in terms of size, shape, material, and performance. We can accommodate both small lot, short-run custom orders, and large production quantities, ensuring that you receive the perfect solution for your needs.

Contact Us Today:

At viiplus.com, we are dedicated to providing the highest quality self-lubricating copper sleeve bushings at competitive prices. Contact us today to learn more about our products and services and discover how we can help you achieve optimal performance in your mechanical systems.

Self-Lubricating Bearings Products by Application:

-

Food and Beverage Industry: Our self-lubricating bushings are designed to comply with strict hygiene standards and ensure smooth operation in food processing and packaging machinery.

-

Chemical Industry: Our bushings are made from corrosion-resistant materials, making them suitable for use in chemical processing and handling equipment.

-

Cosmetics Industry: Our self-lubricating bushings are designed for precision and reliability, ensuring optimal performance in cosmetics production and packaging machinery.

-

Pharmaceutical Industry: Our bushings meet stringent quality standards and are suitable for use in pharmaceutical processing and packaging equipment, ensuring safety and compliance.

-

Heavy Machinery: Our high-quality bushings provide durability and wear resistance for heavy machinery used in construction, mining, and other demanding applications.

-

Automotive Industry: Our self-lubricating bushings are designed to withstand high loads and temperatures, making them suitable for various automotive applications, such as engines, transmissions, and suspension systems.

-

Aerospace Industry: Our bushings are designed to meet the specific requirements of the aerospace industry, providing reliable performance in aircraft components and systems.

Why Choose Us for Your Packaging Bushing Manufacturing Needs?

-

Comprehensive Solutions: We offer a wide range of self-lubricating bushings and bearings, providing a one-stop solution for your specific application requirements.

-

Expertise: Our team of experienced engineers and technicians are committed to delivering the highest quality products and ensuring customer satisfaction.

-

Customization: We can tailor our self-lubricating bushings and bearings to your unique specifications, ensuring optimal performance and compatibility with your machinery.

-

Competitive Pricing: Our cost-effective manufacturing processes allow us to provide high-quality products at competitive prices.

-

Continuous Innovation: We constantly research and develop new materials and processes to improve the performance and durability of our bushings, helping customers overcome technical challenges in various industries.

Get in touch with us today to learn more about our self-lubricating bronze bearings and copper sleeve bushing solutions. Let us become your trusted partner in delivering exceptional bushing products tailored to your specific needs.

Application of Graphite Copper Sleeve in Construction Machinery

The copper sleeve is a crucial mechanical lubrication component, and due to variations in materials and technologies, it is available in numerous types. Each copper sleeve has distinct characteristics, which leads to slightly different choices across various industries. For construction machinery, the most commonly used type is the graphite copper sleeve.

Graphite copper sleeves are manufactured using graphite, which has a relatively relaxed structure that simplifies hole drilling and preparation for subsequent operations. The perforated copper sleeve surface is embedded with a solid lubricant, forming a self-lubricating bearing that reduces lubricating oil consumption and enhances construction machinery’s operational efficiency.

As construction machinery continues to grow and improve, the demand for components such as copper sleeves and bearings is rapidly increasing. Among these components, the copper sleeve is the most critical, as it is the core element that enables the machinery to function. Choosing the right copper sleeve is essential for optimal performance.

The combination of graphite copper sleeves and self-lubricating bearings allows construction machinery to operate efficiently while minimizing raw material usage and enhancing work efficiency. Therefore, for complex and precise equipment such as large machinery, heavy machinery, and construction machinery, it is recommended to use graphite copper sleeves and self-lubricating bearings to ensure product excellence and high quality.

Bronzelube.com offers professional graphite copper sleeves and self-lubricating bushings. With many years of production experience, our products are widely used in various industries, including automotive, construction machinery, hydraulic machinery, wind power, high-speed trains, plastic machinery, and automatic production lines. The graphite copper sleeve base is typically made of brass, tin bronze, or aluminum bronze, but the specific material should be determined according to the bearing’s working conditions. Commonly used materials include high-strength brass, tin bronze, and castings.

By combining different metal matrices with embedded solid lubricants, we can tailor our products to meet the unique requirements of various working conditions, such as temperature, load, motion, and medium, ensuring stable and reliable performance. Our factory specializes in producing various specifications and materials of graphite copper sleeves, graphite copper tiles, self-lubricating slide plates, and other graphite products. Additionally, we produce copper sleeves, copper tiles, copper slide plates, copper worm wheels, copper nuts, cast aluminum, and zinc-based alloy pieces, among other non-ferrous metal products.

Learn more about our graphite bushings made in China and find the perfect solution for your construction machinery needs. For more information or custom processing based on your drawings, please contact us!

Price and delivery time on request

Self-Lubricated Copper Sleeve Factory Order Item

Self-Lubricated Copper Sleeve Factory: Your One-Stop Solution for High-Quality Bearings and Bushings

We specialize in manufacturing and supplying self-lubricated copper sleeve bushings and bearings for various industries, including food, beverages, chemical, cosmetics, and pharma. Our fully automatic packaging copper sleeve bushings are designed to save material costs while ensuring optimal performance, making us a leading bronze sleeve bushings supplier.

Packaging Machine Bronze Bearing Manufacturer – Packaging Machines Flange Bushing: As a leading bronze sleeve bushings supplier, we offer a wide range of bushings and bearings for packaging machines, including flange bushings. Our products are designed to enhance the performance of your packaging machinery, ensuring smooth operation and reduced downtime. Contact Us Today for Your Self-Lubricated Copper Sleeve Bushings: We are committed to providing high-quality self-lubricated copper sleeve bushings at factory prices. Our dedication to customer satisfaction, along with our professional advice and perfect after-sales service, makes us a leading choice for your bushing and bearing needs. Contact us today to discuss your requirements and discover how we can help you improve the performance of your machinery with our self-lubricated copper sleeve bushings.

Be inspired by our CAD Library.

Customized Self-Lubricating Bearings Copper Sleeve Products for Packaging Manufacturing

Projects

Your One-Stop-Shop for Packaging Bushing Manufacturing

Explore self-lubricating bearings products tailored for various applications. As a professional exporter and supplier of self-lubricating bronze bearings and copper sleeve bushings in China, we are dedicated to providing customers with high-quality, cost-effective flange bronze bushing products. Our continuous material innovation helps customers overcome technical challenges across numerous industries.

Choose Your Industry: Oilless Bearing Online Global Sales

Experience reliability and innovation with our oilless bearings global sales, specializing in the export of self-lubricating bearings. High-quality products and precision bearings are our pursuit, with customer satisfaction at the forefront of our priorities. We strive to create value through high-performance self-lubricating bearing solutions and contribute to caring for the Earth. Our standard products maintain excellent performance in various applications, such as: High-speed rotational motion, High-speed linear motion. Additionally, our bearings perform economically well in medium and low-speed linear motion, ensuring cost-effective solutions for your specific needs. Explore More: Visit our website to learn more about our wide range of self-lubricating bearing solutions tailored to your industry. Browse through our extensive catalog of products and find the perfect fit for your application requirements. Type of Self-Lubricated Bushing, Made in China:

- Graphite Copper Sleeves

- Oilless Bronze Bearings

- Flange Bronze Bushings

- Solid Lubricant Embedded Bushings

- Bi-Metal Bushings

“We Are Here for You: Maintenance-Free Copper Sleeve & Bronze Bearing”

We are dedicated to supplying and exporting semi-automatic bushings, automatic high-speed bottling lines bronze bearings, and packaging machines bushings. Our commitment to customer satisfaction drives us to provide the highest quality bronze bushings and oilless bearings products at cost-effective prices. As a quality-conscious supplier, we assure you that our premium quality standards are never compromised. To make your experience seamless and convenient, we offer various payment options. Learn More: Discover more about our wide range of self-lubricated bushings made in China, designed to cater to various industries and applications. Visit our website to explore our extensive catalog of products and find the perfect solution for your specific needs. Our team of experts is always available to answer any questions and help you choose the right bearing solution for your unique requirements.

We are committed to delivering top-quality self-lubricating bearing solutions for diverse industries. Our dedication to customer satisfaction, innovation, and global sales ensures that you receive the best products and services available in the market. Contact us today to learn how our maintenance-free copper sleeves and bronze bearings can enhance the performance and efficiency of your machinery.

Your Strategic Global Partner in Sliding Bearing Technology

Bronze Bushing Maintenance: Looking for expert assistance in packaging applications? We are here to provide you with innovative self-lubricating bearings solutions. Visit our website, bronzelube.com, to explore our range of size bushings for customized services and applications.

Utilizing graphite copper sleeves produced through casting and precision machining, we offer a one-stop manufacturing production line for casting and machining. Our commitment to quality ensures that we provide customers with precision casting parts that meet stringent application conditions. Our self-lubricating shaft sleeves are ideal for various applications, including excavators, packaging machinery, and more.

We pride ourselves on being a strategic global partner in sliding bearing technology. Our extensive knowledge and expertise enable us to deliver top-quality, customized solutions for your specific needs. Contact us today to learn how we can help enhance the performance and efficiency of your machinery with our innovative sliding bearing solutions.

We offer a large selection of graphite copper sleeve and flange bushing.

MAINTENANCE Self-lubricating flange bushing, highly durable, and reliable bushing supplier with or without graphite plugged. Learn more!

CUSTOM-MADE STANDARD PRODUCTS

Learn More