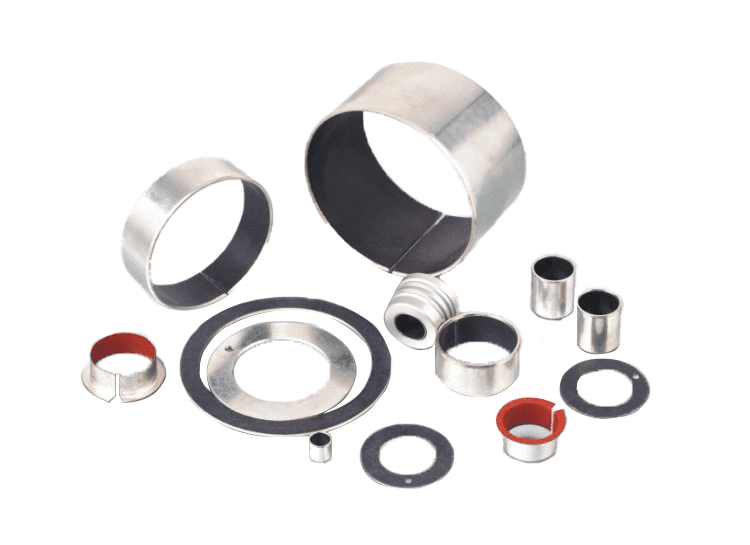

Innovative Hydraulic Bushing Solutions

GEAR PUMPS AND GEAR MOTORS BUSHINGS, Survive Upsets & Dry Running.

Self-lubricated bushings improve the reliability & efficiency of pumps.Non-galling.Run dry & keeps running。 Highlights: Over 10 Years Of Quality & Service Experience, Chat Support Available. gear pump bushing manufacturers & suppliers! Benefits

- Self-lubricating bearings for great overload capacity, vibration and shock

- Quiet, damped operation

- High power density

- Excellent efficiency

- Maintenance free

Quality Gear Pump Bushing Part Less Money.

Metal-Polymer Plain Bearings Grease Lubricated Gear Pump Bushing

Gear Pump Bushing, bushing life calculation. It is a special formula product designed and launched based on the structure of PTFE material and according to the high PV value of the gear oil pump. The product has special anti-fatigue shock advantages. Applicable oil pump pressure: 16-25Mpa, linear velocity 3.5-5m/s. In the realm of fluid lubrication, the PV value can reach 120 N/mm2.m/s. It is the best choice for various gear oil pumps, plunger pumps, and vane pumps.

Bushing Blocks and Thrust Plates Material

1:PTFE&Fiber mix

2:Cu90Sn10

3:Copper back

4:Anodized coating-Cu/Sn/Zinc

We manufacturing pump bushing tailored to your individual needs.

Self-lubricating bearing for gear pump

Self-lubricating bearing life is the key for gear pump customers to choose us, and we are proud to meet more and more partners on the road to breakthrough innovation. Auto parts manufacturer to explore new business opportunities, tractor gear pump market, self-lubricating bearings in the field of steering and suspension systems have many years of experience, in recent years, plans to expand the company’s business scope and influence in the tractor market with new gear pump self-lubricating bearing products. As the core self-lubricating bearing bushing components, the reliability of the gear pump’s bearings directly affect the tractor’s operating performance and life. In the early stages of product design, the customer had tested bearing solutions from other suppliers, but the results were always unsatisfactory and the critical bearing wear problem could not be properly solved.

To ensure product quality, the customer needed a partner who could provide professional and extensive engineering knowledge and who was willing to be deeply involved in design and production. Finally, they chose bronzelube.com

Sliding Bearing Pump Bushing Solutions

After intensive research and testing, we finally recommended that the customer use a metal composite bearing that is well proven in the gear pump industry and has the following characteristics.

- Excellent low friction and wear resistance

- Excellent resistance to cavitation and cavitation

- Very good fatigue strength

- Lead-free materials meet ELV WEEE and RoHS specifications

The self-lubricating composite bushings passed the final product evaluation with better resistance to cavitation, cavitation, contamination and fatigue strength in a demanding testing environment. Multiple material tests have shown longer bearing life and lower wear rates compared to similar products.

Why Choose Us

Customers choose us from a wide range of service providers because of our industry expertise and experience, and the close working relationships we have developed over the course of our work. We were recognized by our customers for the expertise demonstrated by our professional account representatives, which allowed us to successfully work with them to help make their gear pump products a great success. The good relationship has led to a decision by the customer to keep us involved in the development and manufacture of new products.

Metal-Polymer Hydrodynamic Composite Bearings, OEM/ODM Provider, One-Stop Service

Design Assistance

Professional Engineering Team,

Reduce The Reasonable Cost. Global website www.bronzelube.com, Contact Us!

Storage & Logistic

External Gear Pumps and Motors. Help Customers Look After Goods Matching The Delivery Time.

Cost-effective alternative to gear pump bearings

Bushing Design. Low-Friction Pump Bearings – Gear Pumps & Motors,Control Valves Bushing Tech. Data

| Performance | Data | |

| Max. load P | Static | 250N/mm² |

| Dynamic | 140N/mm² | |

| Max. speed V | Dry running | 2.5m/s |

| Oil | 10m/s | |

| Max. PV | Dry running | 4.2N/mm²・m/s |

| Oil | 60N/mm²・m/s | |

| Friction coefficient μ | 0.03~0.18 | |

| Temp. | -195℃~+280℃ | |

| Thermal conductivity | 42W/m・K |

Hydraulic Cylinders Bushing

Gear Pump Bushing- Compact & Very Light – bronzelube.com

※We have been providing gear pump bushing products at competitive prices for more than 10 years. China Manufacturer. Factory Supply. Gear Pump Bushing Material Available. Quick Reply in 24h. Fast Delivery. Various Bushing Sizes.Long Service Life.

* Lubricated Gear Pump Bushes forms available in standard dimensions.

Self-lubricating Bearing Bushing

The oilless bushing for our extensive catalogue. If this standard is not suitable for operating your product, our in-house production at means that we can custom everything on the bearing bushing. If you are interest-ed, talk to us today! Metal-Polymer Plain Bearings Grease Lubricated Bushings Bearings-Sleeves, Flanges, and Washers and More. Standard & Made-To-Order Bronze Bushings And Related Bearing Products. POM Sleeve Bearings. Cast Bronze. Highlights: Customer Service Available. Always tested. Always proven. Always Bronzelube.com

So what can we do for you?

Breathtaking design for home living.

Bushing design. Do you have any questions or suggestions, or do you need expert advice about our products? We are more than happy to help you further.

Nam aliquet ante porta, gravida elit interdum, luctus porta sapien justo, at fringilla felis suscipit vestibulum.