Price & Delivery Time on Request: Exploring the World of Self-Lubricating Polymer Bushings

In the realm of sliding bearing technology, self-lubricating polymer bushings have emerged as a remarkable innovation. With their ability to excel in high-temperature applications while requiring minimal maintenance, these plain bearings have garnered significant attention in various industries. This article aims to delve into the features and advantages of self-lubricating polymer bushings, while shedding light on the price range and delivery time associated with these high-performance components.

Low Maintenance

Self-lubricating polymer bushings eliminate the need for external lubrication, reducing maintenance efforts and costs. They are designed to operate efficiently over extended periods without the need for frequent re-lubrication or maintenance interventions.

High Temperature Resistance

These bushings can endure elevated temperatures without compromising their performance. They exhibit excellent thermal stability, making them suitable for applications involving extreme operating conditions.

Cost-Effective Solutions

Self-lubricating polymer bushings offer cost-effective alternatives to traditional metal-based bearings. Their extended service life, reduced maintenance requirements, and lower initial costs make them an attractive choice for budget-conscious buyers.

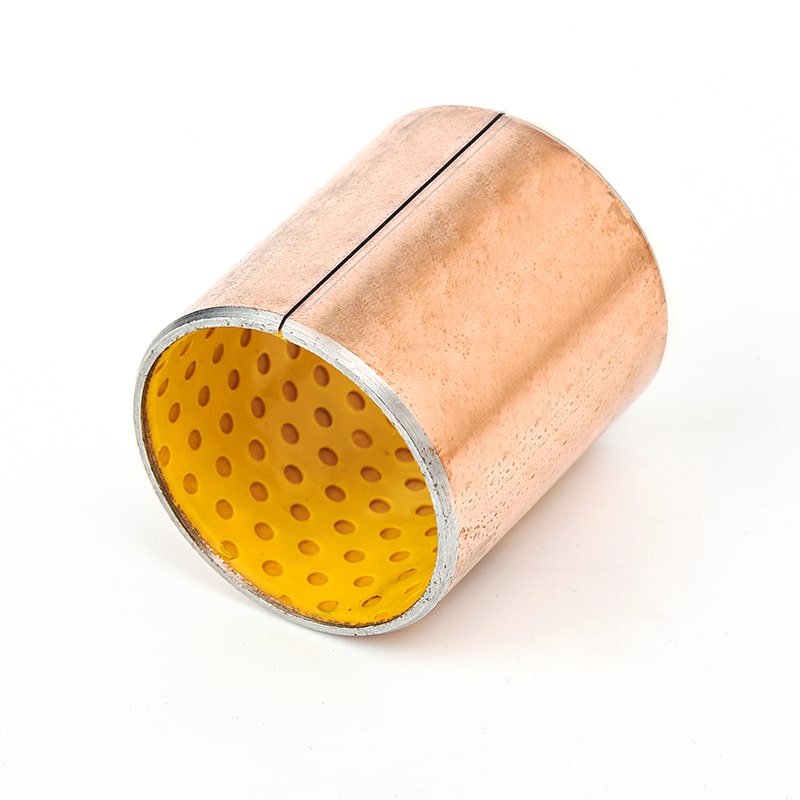

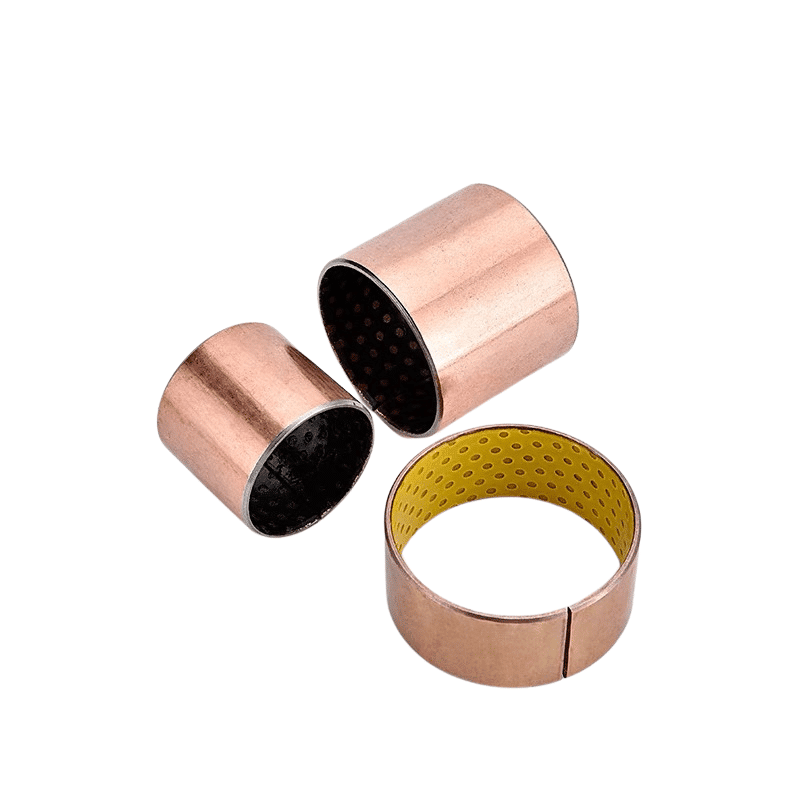

Self-Lubricating Polymer Bushings

Self-lubricating polymer bushings, also known as plain bushes or self-lubricating bearings, are cylindrical bushes made from composite materials. These materials possess exceptional tribological properties, ensuring smooth and friction-free sliding between two surfaces. The bushings are engineered to withstand high temperatures, making them ideal for demanding applications in industries such as automotive, aerospace, and manufacturing.

Self-lubricating Bushings & Polymer Coatings Solutions: Enhancing Performance and Efficiency

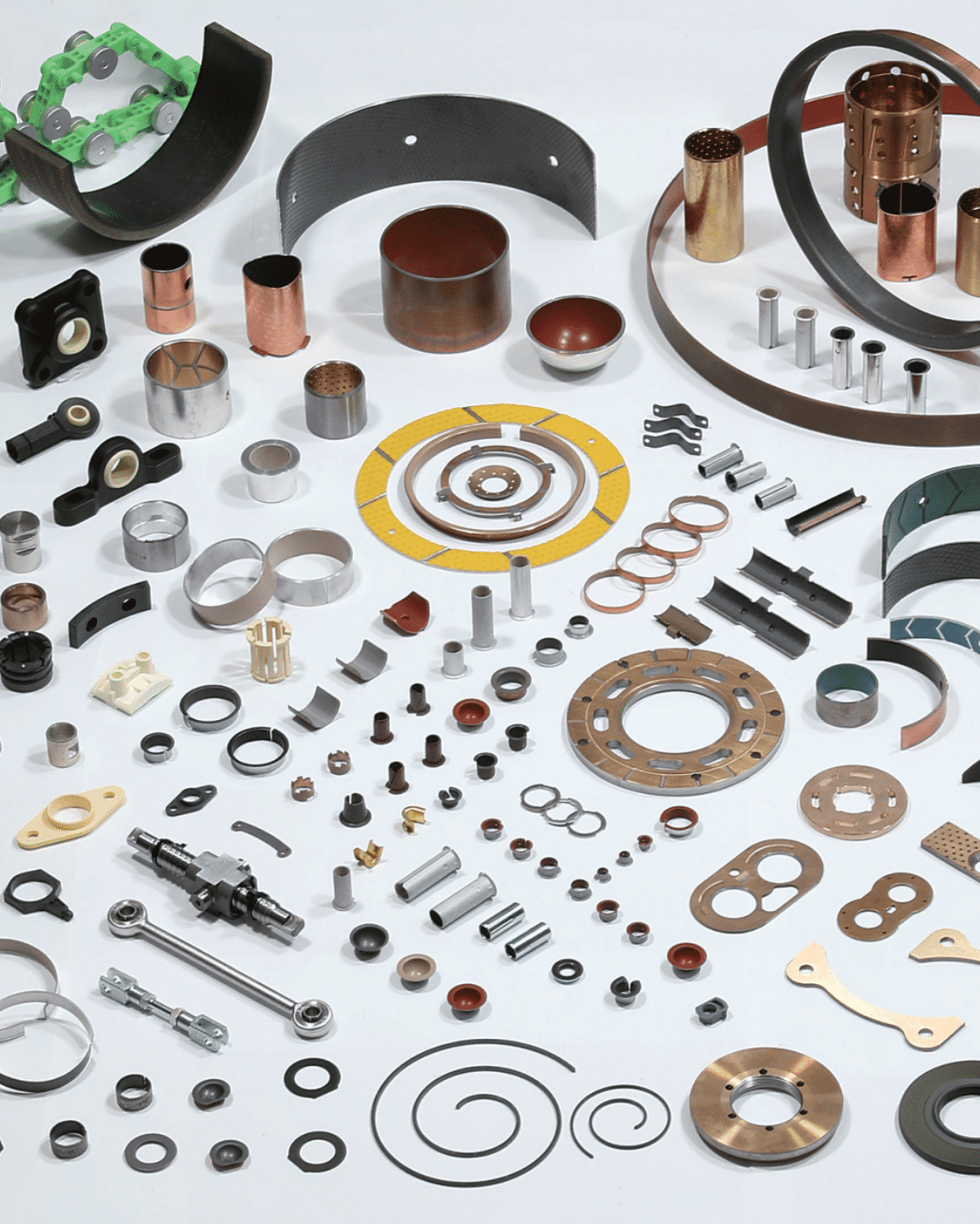

Self-lubricating bushings offer several advantages over traditional roller bearings. By integrating lubrication properties directly into the bushing material, they eliminate the need for additional lubricants. This not only simplifies maintenance but also reduces the risk of lubrication-related failures. Self-lubricating bushings excel in various industries, including agriculture, automotive, construction, energy, fluid power, general industrial, primary metals, oil and gas, and recreational sectors.

Polymer Coatings:

Polymer coatings provide an additional layer of protection and performance optimization for various components, including bushing parts. These coatings offer tribological benefits and can be applied to a wide range of industries, such as agriculture, automotive, construction, energy, fluid power, general industrial, primary metals, oil and gas, and recreational sectors.

Self-lubricating bushings and polymer coatings

Self-lubricating bushings and polymer coatings offer innovative solutions for various industries, improving performance, efficiency, and durability while reducing maintenance efforts and costs. These advanced components eliminate the need for external lubricants, simplify assembly, and provide reliable operation in diverse applications. By exploring the benefits and applications of self-lubricating bushings and polymer coatings, companies can unlock new possibilities for their manufacturing facilities and achieve enhanced safety, comfort, and overall operational excellence..

Self-lubricating Composite Bearing Price Range:

The price of self-lubricating polymer bushings can vary depending on several factors such as the specific material composition, size, quantity, and supplier. As each application may have unique requirements, it is advisable to request a price quote tailored to your specific needs. Manufacturers and distributors typically provide pricing details upon request, allowing you to obtain accurate and up-to-date information.

self-lubricating polymer bushings

Delivery Time

Delivery times for self-lubricating polymer bushings can also vary, depending on factors such as order volume, manufacturing processes, and supplier capabilities. To obtain precise delivery time estimates, it is recommended to contact the manufacturer or supplier directly. They can provide you with information based on your order specifications, ensuring a clear understanding of when you can expect your products to be delivered.

Sliding Bearing Solution: Unleashing the Power of Polymer Coatings and Self-Lubricating Bushings

Self-lubricating polymer bushings

Self-lubricating polymer bushings have revolutionized sliding bearing technology with their ability to withstand high temperatures, minimize maintenance requirements, and provide cost-effective solutions. When considering the purchase of these high-performance components, it is essential to inquire about the price range and delivery time. By reaching out to manufacturers or suppliers and providing specific details about your requirements, you can obtain accurate pricing and delivery information, enabling you to make informed decisions for your bushing needs. Remember, the right self-lubricating polymer bushings can enhance the performance and longevity of your applications while minimizing maintenance costs in the long run.

reliable tribology and friction bearing bushing

Support & Delivery

When it comes to reliable tribology and friction reduction, bronzelube.com stands as a leading design partner offering expertise in polymer coatings, plain bushes, and self-lubricating bushings. With a global presence, they provide superior-quality solutions that empower engineers to push the boundaries of performance. This article explores the benefits and capabilities of polymer coatings and self-lubricating bushings, highlighting how they enable high-performance bearing solutions for various industries.

Polymer Coatings for Greater Design Freedom:

Bronzelube.com specializes in polymer coatings that provide engineers with enhanced design freedom. These coatings are formulated with specific properties to meet the demands of different applications, enabling engineers to surpass performance boundaries. Regardless of the shape or composite bearing material, polymer coatings offer exceptional versatility and performance optimization.

Bronzelube.com, with its expertise in polymer coatings, plain bushes, and self-lubricating bushings, offers high-performance sliding bearing solutions for diverse industries. Their polymer coatings provide engineers with greater design freedom, enabling them to optimize performance beyond traditional boundaries. Additionally, the self-lubricating bushings offer low maintenance, reduced friction, and extended service life, ensuring superior performance in demanding applications. Whether you require friction reduction, corrosion resistance, or customized solutions, bronzelube.com stands ready to partner with you, providing reliable tribology solutions that enhance the efficiency and longevity of your bearing systems.

Advantages of Polymer Coatings

Self-Lubricating Bushings for Superior Performance: Bronzelube.com also offers self-lubricating bushings, which are designed to operate without the need for additional external lubrication. These bushings are engineered with specialized materials that provide built-in lubrication properties, ensuring low friction and minimal maintenance.

Friction Reduction: Polymer coatings excel in reducing friction between two sliding surfaces, ensuring smooth and efficient operation. By minimizing wear and tear, they enhance the lifespan and reliability of bearing systems.

Customization: Polymer coatings can be tailored to meet specific application requirements, allowing engineers to optimize performance for their unique needs. This customization extends to factors such as load capacity, temperature resistance, and compatibility with different mating surfaces.

Corrosion Resistance: Polymer coatings provide excellent protection against corrosion, extending the longevity of bearing systems. This feature is particularly valuable in industries exposed to harsh environments or corrosive substances.