arm bushing

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

arm bushing

Unleashing Potential with Innovative Arm Bushing Design

A Deep Dive into the Robotic Arm Oilless Self-Lubricating Bushing System at Bronzelube.com, The industrial realm has witnessed dramatic shifts in the way machinery operates, primarily due to innovative advancements in the field of robotics. Among these advancements, a key highlight is the design of industrial manipulator arm bushing systems. This intricate element often takes center stage when assessing the performance and efficiency of robotic arms. Particularly noteworthy are oilless, self-lubricating bushing designs available at Bronzelube.com, known for their durability, reliability, and contribution to environmental sustainability.

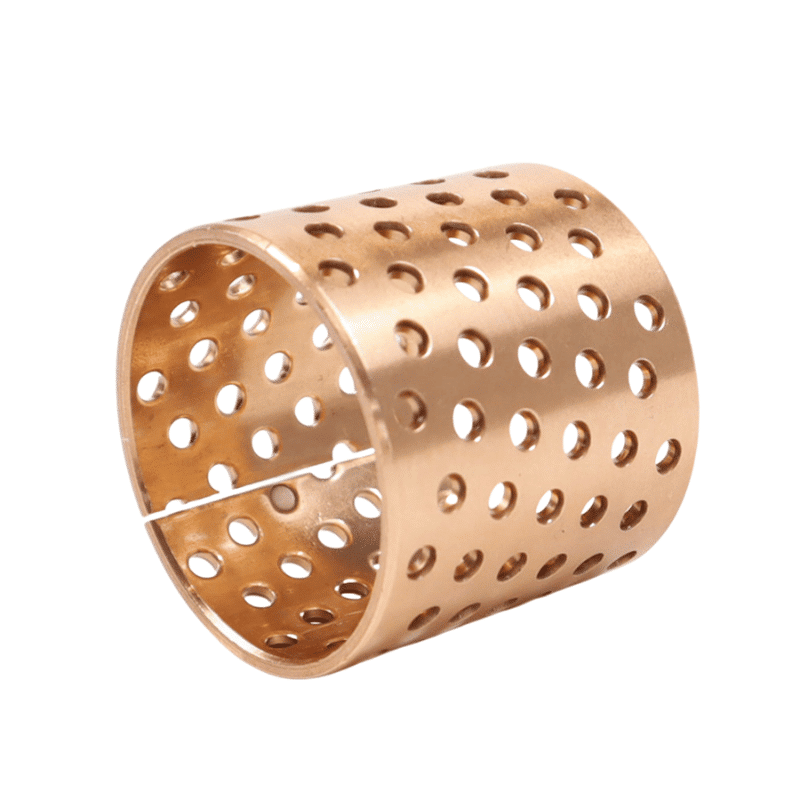

Discover the Arm Bushing, The Revolution of Self-Lubricating Arm Bushing Bearings: A Look at Metal Bronze Sleeves

specializing in Arm Bushing Design

To understand the true value of the robotic arm bushing design, one needs to familiarize themselves with its applications and the steps involved in its design. The arm bushing, often crafted from bronze, plays a significant role in the operational dynamics of industrial manipulators, more commonly known as robotic arms.

Robotic arms are highly versatile, performing a myriad of functions in various industrial applications, from assembly lines to precision tasks in the medical field. The performance of these arms relies heavily on the bushing design. In essence, a well-designed bushing promotes efficient energy transfer, reduces wear and tear, and ultimately enhances the lifespan and performance of the robotic arm. The Power of Metal Bronze Sleeves: The use of metal bronze sleeves in the design of these self-lubricating arm bushing bearings further enhances their performance. Bronze, as a material, is renowned for its excellent load-carrying capacity, resistance to impact, and outstanding wear and corrosion resistance.

These properties, combined with the self-lubricating feature, make bronze sleeve bearings an ideal choice for high-load, high-speed applications, such as those found in industrial manipulators. The self-lubricating bronze sleeves ensure a consistent, smooth operation, reducing maintenance needs and the associated costs and downtime.

specializing in Arm Bushing Design

In the realm of robotics and industrial machinery, the advent of self-lubricating arm bushing bearings has ushered in a new era of efficiency, durability, and environmental sustainability. More specifically, the metal bronze sleeves, designed with an inherent capacity to reduce friction, have significantly transformed the operational dynamics of industrial manipulators or robotic arms.

Unraveling the Magic of Self-Lubricating Arm Bushing Bearings

A fundamental challenge in robotics and machinery is the need to reduce friction between moving parts to ensure smoother operations, extend the lifespan of the equipment, and mitigate maintenance requirements. Traditionally, this has been achieved through regular lubrication using various types of oils and greases.

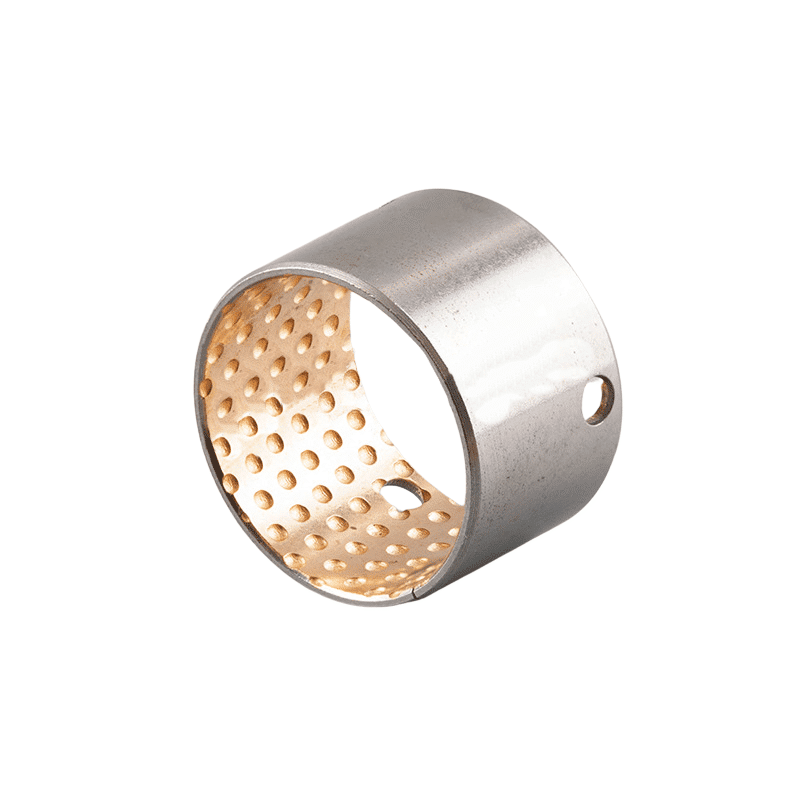

Bimetal Arm Bushing

Harnessing the Power of Bimetal Steel Bronze Alloy in Arm Bushing Bearings: A Leap Forward in Efficiency

Industrial machinery and robotic systems are continually evolving, with each new innovation bringing enhanced performance and efficiency. A prime example of this innovation is the use of bimetal steel bronze alloy in the design of arm bushing bearings. This combination of metals ushers in a new era of durability and functionality for the machines that form the backbone of our industries.

Understanding Bimetal Steel Bronze Alloy Arm Bushing Bearings

Arm bushing bearings, a critical component in robotic arms and other machinery, serve as the linchpin for smooth, efficient operation. Traditionally, these bearings have been made from a variety of materials, with the choice of material significantly affecting the bearing’s performance.

Enter the bimetal steel bronze alloy arm bushing bearings – an innovation designed to meet the rigorous demands of modern industry. This unique combination merges the strength and durability of steel with the superior frictional properties and wear resistance of bronze.

In these bimetal bushings, a layer of bronze alloy is bonded to a steel backing. The steel provides excellent support and shock resistance, while the bronze layer delivers a low friction surface that reduces wear and tear, even under high load and speed conditions.

The Advantage of Bimetal Bearings

The use of bimetal steel bronze alloy in arm bushing bearings provides several significant benefits:

-

Durability: The strength of steel and the wear resistance of bronze combine to offer a long-lasting, robust bearing that can withstand demanding industrial applications.

-

Efficiency: The bronze layer’s low friction properties result in smoother operation, contributing to overall machine efficiency.

-

Versatility: These bearings can be used in a variety of applications, from high-temperature environments to those with high-speed or high-load requirements.

-

Cost-effectiveness: Bimetal bearings typically require less maintenance, reducing downtime and associated costs.

The Bronzelube.com Advantage

Bronzelube.com offers a wide selection of bimetal steel bronze alloy arm bushing bearings, enabling you to benefit from the durability and efficiency these innovative components provide. With their commitment to fast shipping and exceptional customer service, Bronzelube.com makes it easy for you to incorporate these advanced bearings into your machinery.

Ready to experience the power and efficiency of bimetal steel bronze alloy arm bushing bearings? Visit Bronzelube.com or give us a call today to place your order and take the first step towards enhanced machine performance.

Maximizing Efficiency with Rocker Arm Bushing Bimetal Bearing Bushes: An Exploration into Performance Enhancing Components

In the world of industrial machinery and automotive engineering, the rocker arm bushing plays a vital role in achieving operational efficiency. The introduction of bimetal bearing bushes into rocker arm bushing design is a game-changer, providing enhanced durability, efficiency, and reduced maintenance needs.

Unveiling the Rocker Arm Bushing Bimetal Bearing Bushes

Rocker arm bushings, integral to the valve mechanism of internal combustion engines or sophisticated robotic arms, are subject to high loads and rigorous operational conditions. Traditionally, these bushings demanded frequent lubrication and maintenance to sustain their performance and longevity.

The innovative design of bimetal bearing bushes has significantly changed this narrative. Composed of two different metals, typically steel and bronze, these bimetal bearing bushes offer unparalleled advantages in terms of durability, friction reduction, and maintenance requirements.

The design involves a layer of bronze alloy bonded to a robust steel backing. While the steel lends its strength and shock resistance, the bronze layer brings to the table excellent frictional properties and wear resistance. This strategic combination ensures a long-lasting, smooth operation even under high-stress environments.

Benefits of Rocker Arm Bushing Bimetal Bearing Bushes

-

Durability: The amalgamation of steel’s strength and bronze’s wear resistance makes the bimetal bearing bushes highly durable, able to withstand the strenuous demands of rocker arm bushings.

-

Reduced Friction: The bronze layer in the bimetal bushings provides a low friction surface, thereby reducing wear and extending the life of the bushing and associated components.

-

Maintenance Savings: Given their self-lubricating nature, bimetal bearing bushes drastically reduce the necessity for regular maintenance and lubrication, recognized to significant time and cost savings.

-

Versatility: Owing to their robust design, bimetal bearing bushes are suitable for a wide array of applications, including those with high load, high speed, or high temperature requirements.

Empower Your Machinery with Bronzelube.com

Bronzelube.com, with its extensive collection of bimetal bearing bushes, offers you the opportunity to enhance the efficiency and longevity of your machinery. Committed to delivering exceptional service, Bronzelube.com ensures fast shipping for your convenience.

If you’re ready to experience the transformative impact of rocker arm bushing bimetal bearing bushes on your operations, visit Bronzelube.com or give us a call today. Elevate your machinery’s performance while minimizing maintenance requirements and associated costs with bimetal bearing bushes.

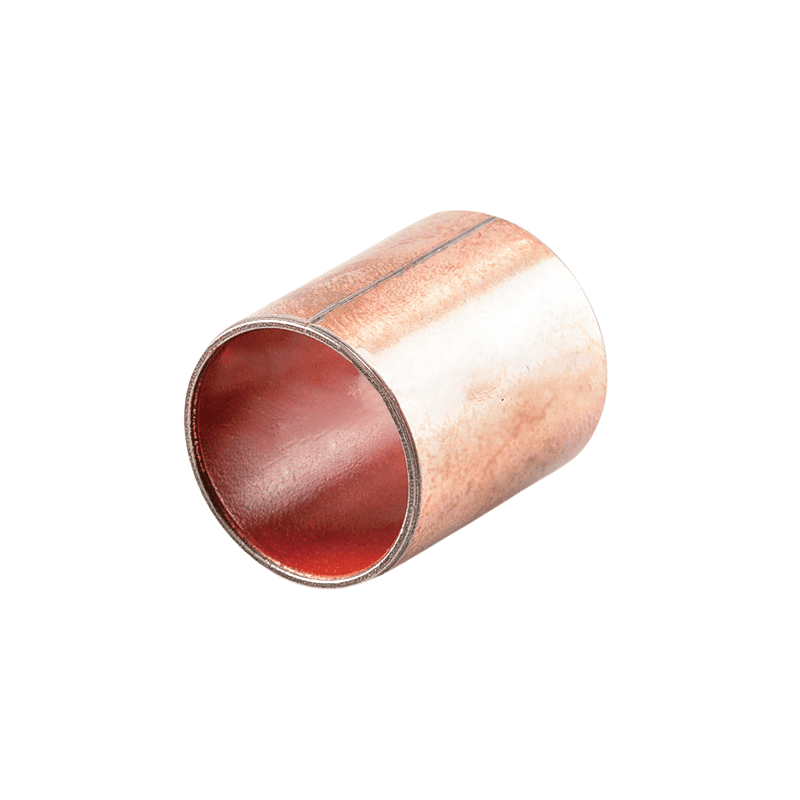

Streamlining Operations with Wrapped Bronze Arm Bushing: A Deeper Dive into Self-Lubricating Tin Bronze Bushes

The evolution of industrial machinery and robotics has seen a shift towards increasingly efficient, durable, and maintenance-friendly components. A prime example of this innovative trend is the integration of wrapped bronze arm bushing and self-lubricating tin bronze bushes in the design of industrial equipment. This technological advancement significantly enhances the performance and lifespan of machinery, while simultaneously reducing maintenance needs.

Unraveling the Wrapped Bronze Arm Bushing

The arm bushing, a critical component in industrial machinery and robotic arms, has a profound impact on the smooth operation and longevity of these systems. Traditional bushings often require regular lubrication to maintain optimal functionality and prevent wear and tear.

The introduction of wrapped bronze arm bushings marks a significant leap forward in bushing design. These bushings are created by wrapping a bronze strip around a mandrel, which is then removed to leave a seamless, cylindrical bushing. This design offers superior load-carrying capacity and wear resistance compared to traditional bushings.

Tin Bronze Bushes: A Self-Lubricating Marvel

Taking the innovation a step further, self-lubricating tin bronze bushes have been introduced. These bushes consist of a wrapped bronze bushing infused with tin, offering enhanced wear resistance and lubricity. The unique characteristic of these bushes is their inherent self-lubricating properties.

These bushes are embedded with lubrication pockets during manufacturing, which gradually release lubricant during operation, creating a thin film on the bushing surface. This self-lubrication process significantly reduces friction, wear, and maintenance requirements, contributing to a more efficient and durable operation.

Key Advantages of Self-Lubricating Tin Bronze Bushes

-

Maintenance Efficiency: Self-lubricating bushes eliminate the need for frequent lubrication, resulting in reduced downtime and maintenance costs.

-

Improved Durability: The incorporation of tin enhances the wear resistance of the bushing, extending its lifespan.

-

Environmental Sustainability: By reducing the need for oil-based lubricants, self-lubricating bushes contribute to environmental sustainability.

Choosing Bronzelube.com for Your Bushing Needs

Bronzelube.com offers a wide selection of wrapped bronze arm bushings and self-lubricating tin bronze bushes, designed to boost the performance and longevity of your machinery. Their commitment to fast shipping and excellent customer service makes Bronzelube.com your ideal partner for all your bushing requirements.

Experience the transformative power of wrapped bronze arm bushing and self-lubricating tin bronze bushes today. Visit Bronzelube.com or give us a call to place your order, and step into the future of industrial machinery performance and efficiency.

Enhancing Machinery Efficiency with Arm Slide Bearing Bushings: The Future of Industrial Motion

In the complex ecosystem of industrial machinery and robotics, every single component plays a pivotal role in ensuring smooth and efficient operations. One such integral part is the arm slide bearing bushing, a component that has been revolutionizing the mechanics of movement in industrial applications.

Understanding Arm Slide Bearing Bushings

Arm slide bearing bushings are specialized bearings designed to facilitate linear motion with reduced friction. These bushings are typically integrated into the arms of industrial machinery and robotic systems, where they play a critical role in ensuring seamless movement and operational efficiency.

Manufactured using materials with low friction coefficients, such as bronze, these bushings are engineered to withstand high loads and speeds, while reducing the wear and tear that results from friction.

The Role of Arm Slide Bearing Bushings

The main role of arm slide bearing bushings is to provide support and guide the movement of various components in machinery or robotic arms. They are especially important in systems where high precision and reliability are required, such as in manufacturing lines, automation systems, and precision instruments.

These bushings work by providing a smooth sliding surface for the moving parts of a machine or robotic arm. This greatly reduces the friction that would otherwise be generated between these moving parts, recognized to smoother operation, reduced wear, and longer lifespans for the components involved.

Benefits of Arm Slide Bearing Bushings

The use of arm slide bearing bushings in industrial machinery and robotic systems offers a number of significant benefits:

-

Increased Efficiency: By reducing friction, these bushings enable smoother and more efficient operation of machinery and robotic systems.

-

Enhanced Durability: The bushings’ wear-resistant properties help to extend the lifespan of the machinery or robotic systems in which they are used.

-

Reduced Maintenance: By minimizing friction and wear, these bushings decrease the need for regular maintenance and replacement of worn-out parts, recognized to cost savings and increased productivity.

self-lubricating arm bushing bearings

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.