Oil Free Bushings from china, always ready to adapt as your business needs

China Company of Self-lubricating Bearings, Sesimic Isolation and Vibration for Various Industries. Oilless Bushing. Bronze Castings. Straight Type. Material Base Solid lubricant Bushing. Machined parts manufacturer with fabrication and tool room capabilities. We specialize in everything from high-volume production runs to sample run offs and prototyping. Supply of C863 Manganese Bronze Bearing and Slide Plate. C863 Manganese Bronze Plate meets SAE 430B specification.

Start Your Best Oilless Bushings Solution, Plain & Self-Lubricating Bushings

Custom manufacturer of precision machined parts including oil-free bearing bushing and thrust washers made from bronze. Manufacturing stocks an inventory of plain bronze sleeve bushings in industry standard sizes. Guided Ejector Bushings, Made of solid aluminum bronze either with or without self-lubricating graphite Guided Ejector Bushings come in a variety of industry standard sizes. If a standard size won’t work for your application, We can easily make a custom size. Please contact us.

www.bronzelube.com has excelled in manufacturing durable, trusted oilless bushing bearings for products around the globe. Our oilless bushing bearings are the top choice for manufacturers in the automotive, marine, and industrial markets. A lot of customer reviews and the high quality oilless bushings buy from us have proven this.

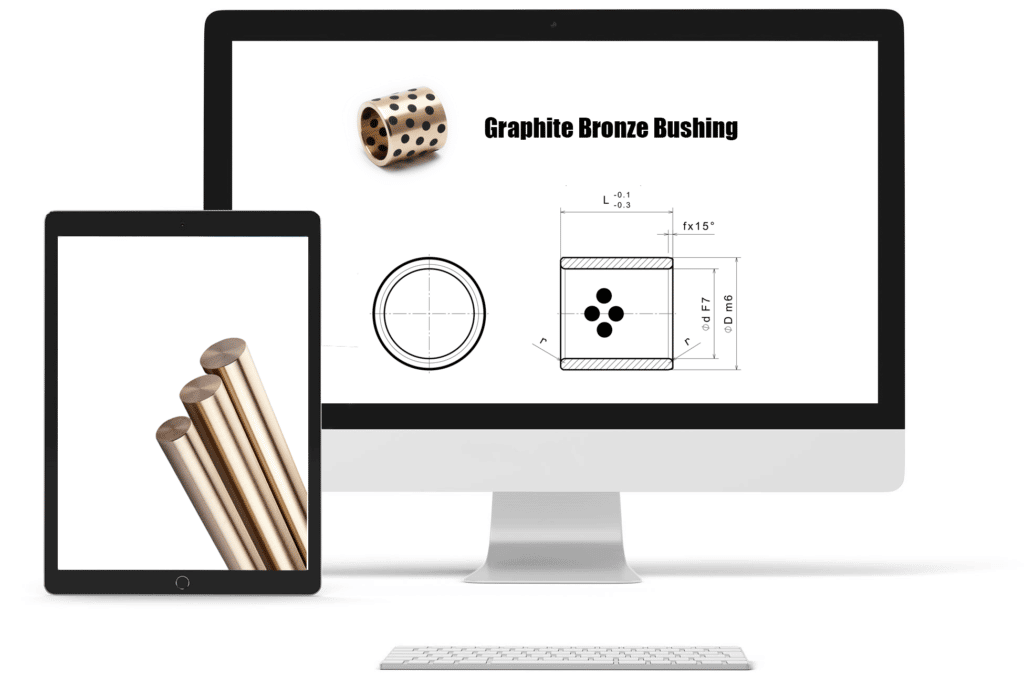

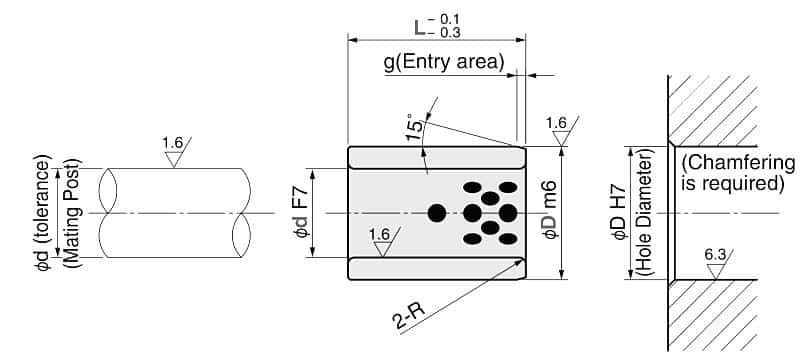

Standard graphite patterns. For special graphite requirements, please contact our bearing company for assistance.

taxation planning

Eiusmod tempor incididunt ipsum ut labore dolore magna aliqua. Ut enim minim veniam duisy ipsum sed quis.

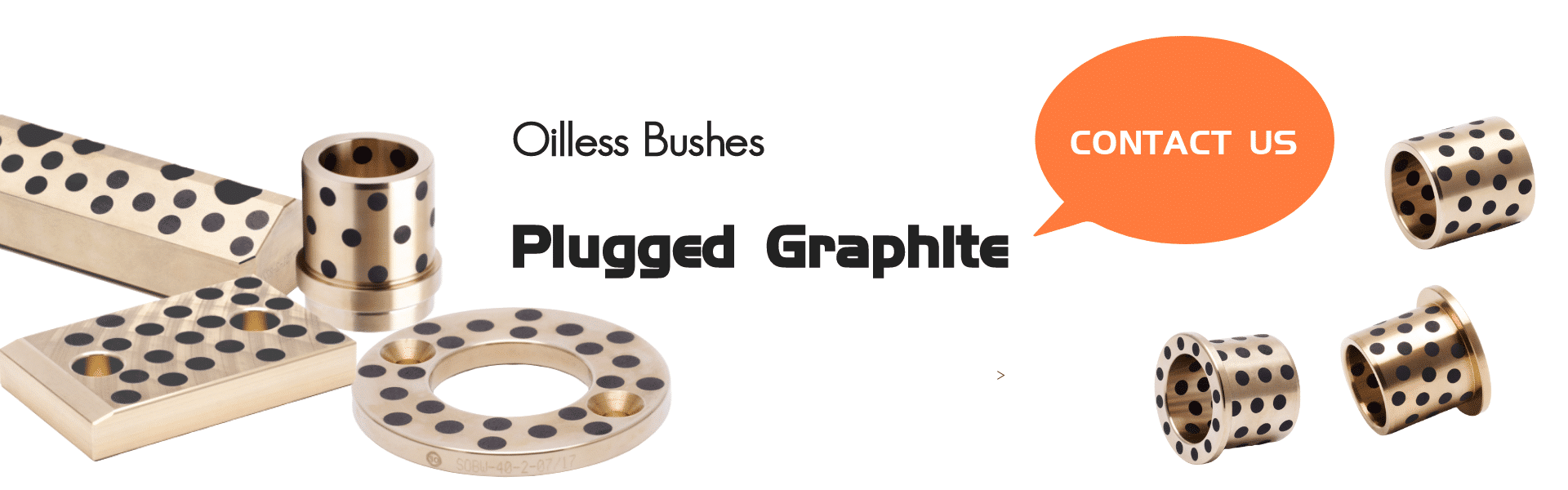

Non ferrous Bushes, 2.0966 bronze material equivalent Oilless Bushing, Graphite Solid Lubrication Materials

Graphing Bearing, Graphite filling is provided on all grooved and drilled parts. Graphite filling is used in grooves and drilled holes because of its self-lubricating properties. Graphite filling is perfect for bushings used intermittently or in low speed environments where the RPM required to form an oil film does not exist. Graphite also works well in high speed environments because it provides lubrication during start-up and shutdown as well as sudden shock load situations.

Custom manufacturer of bronze bearings, cast bronze alloy, aluminum bronze bushing, bronze oil free washers using various machining and CNC machining services. Agriculture, construction, automotive, electronic, electrical, medical, military and other industries served. Made of solid bronze in a wide range of industry sizes, and Shoulder Bushings – Metric, Oil Free Bushings – Flanged, Standard, “Flanged, less likely to pull-out.” Oilless Bushing Feature :Maintenance-free. Excellent wear resistance in applications where oil film formation is difficult such as reciprocating, intermittent or oscillating motions under high loads and low speeds. Aluminium bronze Bushings: Aluminium bronze is a copper-based copper-aluminum alloy that is resistant to seawater, acid and abrasion.

Oil Free Bushing – Brass Alloy, Straight and Flanged Sleeve Bushing – Select, configure, order.

Manufacturer of standard and custom flange graphite washers made from bronze.

As a reliable oilless bushings supplier, we aim to supply the best oilless bushings that cater to the varying needs of our customers. We can be produced according to the customer’s mold oilless bushing design drawings, and our company can refer to technical requirements and standards for production such as “MISUMI”, “Disc”, “HASCO”, “DME” “FIBRO” “DANLY”. Greaseless bushings and bearings, Work in High Temp & Submerged Applications!

Change your oil free bush now & reduce costs by up to 40%

Self-lubricating and maintenance-free, Bearing with Graphite insert. Bushings From China – Quality Components & Solutions. Cast Bronze Bushings with Solid Lubricant Inserts. Oilless bushing – Oilless Self-lubricating Tech, We Strives to Offer Cost-saving, Stable Performance Bearings and Bushings. Contact Us. 100% Quality Guaranteed. Worldwide On-time Shipping. View Our Products. Contact Us…Industrial Bronze Bushings – Made to Order Copper Alloys. Saves You Time & Money In Research, Design & Production Costs. E-mail Now! Copper Alloy Bars , Plates & Parts Specialists For Manufacturing & Machining Of All…

Die Bushings Available either with or without self-lubricating graphite, Die Bushings and Plate are made of solid bronze. They are available in all industry standard (inch) sizes.

Metal Bushings: The Self-Lubricating Effect – Oilless Bushes.

Choose from our selection of self-lubricating bushings, including plugged graphite sleeve bearings, dry-running sleeve bearings, Metallic & Self-Lubricating Bushings and more. Bronze Bushing Sleeve Bearings!Made of solid aluminum bronze either with or without self-lubricating graphite cast bronze bushings – Metric come in a variety of industry standard sizes. If a standard won’t work for your application, We can easily make a custom size. Please contact us.

Custom Parts Services and Prototyping!

Leaded, Phosphor And Aluminium Bronze Bearing, Search Our Material Alloy

Oil-free bearing Supplier, Supplies for Oilless Bushing.

Outstanding Customer Service. Register Online.

We manufacturing self-lubricating maintenance-free bearings tailored to your needs.

Oilless Bushings: A Guide to Finding the Right Supplier

Oilless bushings, also known as dry bushings, are self-lubricating bearings that are designed to function without the need for oil or grease. They are commonly used in a wide range of applications, including automotive, electrical, and mechanical systems, due to their durability and low friction characteristics.

When it comes to selecting an oilless bushing supplier, there are several factors to consider to ensure that you get the best product for your needs. Here are some key factors to keep in mind when choosing an oilless bushing supplier:

Quality: The quality of oilless bushings can vary widely between suppliers, so it is important to choose a supplier that is known for producing high-quality products. Look for suppliers that use high-quality materials and have strict quality control processes in place.

Experience: Experience is an important factor to consider when choosing an oilless bushing supplier. Look for a supplier that has been in business for several years and has a proven track record of producing high-quality products.

Customization: Depending on your specific needs, you may require customized oilless bushings. Choose a supplier that offers customization services and has the ability to produce bushings to your exact specifications.

Cost: Oilless bushings can range in price depending on the supplier, so it is important to consider the cost when making your decision. However, it is important to remember that the cheapest option may not always be the best choice. Be sure to balance cost with quality, experience, and customization to get the best value for your money.

Lead Time: Lead time is another important factor to consider when choosing an oilless bushing supplier. Choose a supplier that has a quick lead time and is able to deliver your bushings in a timely manner.

Technical Support: Technical support is an important aspect to consider when choosing an oilless bushing supplier. Choose a supplier that offers technical support and has knowledgeable staff who can answer any questions you may have about their products.

By considering these factors, you can find an oilless bushing supplier that is able to provide you with high-quality products that meet your specific needs. Whether you are looking for standard oilless bushings or customized solutions, choosing the right supplier is key to ensuring the success of your project.

In conclusion, finding the right oilless bushing supplier is essential to ensuring that you get the best products for your needs. Consider factors such as quality, experience, customization, cost, lead time, and technical support to find a supplier that is able to meet your specific requirements. With the right supplier, you can be confident that you are getting the best oilless bushings for your application.

What is an oil-free bearing bushing? How to lubricate oil-free bearings?

Suitable for vertical use. Reduces the time of manufacturing and assembling the housing. Since Oil Free Bushings do not project from the bushing mounting position. According to the different frictional properties, bearings can be divided into sliding bearings and rolling bearings. There are various classification methods for sliding bearings according to the direction of load, the type of lubricant, the nature of the lubricating film, the structure of the bearing sleeve, the material of the bearing sleeve, etc. Among them, according to the different types of lubricants used in sliding bearings, can be divided into oil-lubricated bearings, grease-lubricated bearings, water-lubricated bearings, gas-lubricated bearings, solid-lubricated bearings, magnetic fluid bearings, and electromagnetic bearings.

The so-called oil-free bearings generally refer to sliding bearings, which belong to the category of sliding bearings. If oil-free bearings are defined by whether the lubricant is oil, water-lubricated, or air-lubricated, then electromagnetic can also be included in oil-free bearings. Today we only introduce this kind of bearing that uses self-lubricating material or oil-containing material, which is made by a special process and works without adding lubricant. It mainly refers to inlaid solid lubrication bearings and self-lubrication bearings.

Oil-free Bearing, plugged graphite, solid lubrication bearing

Oilless bushings are made from PTFE, copper alloy, carbon steel, polyacetal resin & bronze. Oilless bushings are available in various models, dimensions & sizes … China manufacturer of graphite plugged bearings made from C95400 aluminum bronze bushing and C8600 manganese bronze materials. Available in up to 5 in. inner or 6 in. outer dia. and 9 in. length. Self-lubricating bearings for heavy loads and high-temperature applications are offered. Bearings are resistant to corrosion and hostile environments. Suitable for viscous lubricants, oils, and grease applications. Serves the manufacturing, architectural, oil, gas, power generation plant, marine, and naval industries.

Take JDB Oil-free Bearing, plugged graphite series inlaid solid lubrication bearing as an example, it takes metal material as the substrate, on the substrate (brass, tin bronze, aluminum bronze, cast iron, GCr15 and other alloy materials) orderly arranged with suitable size holes, then embedded in oil graphite, PTFE, molybdenum disulfide particles as solid lubrication material. When the bearing works under oil-free lubrication condition, the solid lubricating material will be gradually transferred to the working surface of the friction sub due to the friction heat, thus reducing the friction coefficient.

Inlaid solid lubrication bearings are widely used in light industry, heavy industry, construction, metallurgy, transportation and other mechanical equipment, such as: continuous casting machine, rolling mill, injection molding machine, paper making machine, mold guide pillar, ship, machine tool, etc. Flanged Bushings – Metric Made of solid aluminum bronze with or without self-lubricating graphite. Straight Bushings are available in a wide range of industry sizes.

Self-lubricating bearings -oilless bush, oil free bearing

Self-lubricating bearings are made of self-lubricating materials or oil-containing materials by a special process. Self-lubricating bearings are widely used in the sliding parts of various machinery, such as printing machinery, textile machinery, tobacco machinery, micro motors, automobiles, motorcycles and agriculture and agricultural machinery.

Straight Bushings – Metric, Made of solid aluminum bronze with or without self-lubricating graphite. Straight Bushings are available in a wide range of industry sizes. Made of solid lubricating bronze plugged graphite. Flanged Bushings are available in a wide range of industry sizes. China Oilless Bush manufacturers – Select high quality Oilless Bush products in best price from certified Chinese Bush, China Bushes

Aluminum Bronze Bushing

Custom Cast Bronze Bearings Solutions

Proven Integrity.Delivering Value.

Technical Bronze Standard Parts Experts – Fast and Convenient. Shop for all your Plain & Self-Lubricating Bearings and Plain Bearings & Thrust Washers needs. We offers free CAD download, short lead times, … For example in bushings – aluminum bronze has a tendency to slightly reorganize or redistribute along the axis of motion, thus correcting (or partially correcting) misalignments. Friction, galling and seizure are greatly reduced. In contrast, steel bushings do not have this property, and any misalignment is permanent. Steel bushings are also more likely to damage the pin when worn bushings need to be replaced. All in all, aluminum bronze is a better choice than steel.

Oilless Bushings Supplier, Brass Oil Free Bush

High Quality Oilless Bushings Design & Online Sales

In response to the growing demand for the graphite plugged oilless bushings products, we are pleased to announce that the full line of standard size graphite plugged oilless bushings are available for purchase online at bronzelube.com. Hundreds of industry-standard size oilless bushings are listed in inch and metric standard sizes. These products are inventoried for rapid shipment. Graphite oilless bushings are a complete line of self-lubricating bushings that excel whenever standard lubrication is impractical, including heavy load and high temperature applications. Oil Free Bushings Material: Bronze with solid lubricant, oilless lubricating. Graphite bronze oilless bushings, Oilless Bushing Production, Have Experienced Professional Production & Design Team From China. Made of solid aluminum bronze either with or without self-lubricating graphite, Shoulder Bushings come in a variety of industry standard sizes. Oil Free Bushing Housing Units – Standard Flanged. If a standard size won’t work for your application, We can easily make a custom size. Please contact us.

High Quality Bushes

Designs One Oilless Bearing Bushing Sleeve At A Time. High Quality Oilless Bushings To Meet Your Requirements.

Oilless Bushing Production

Maintenance free brass sleeve bearing and oilless bushings, bronze with solid lubricant.

Specialists in oilless bushing, Quality & Experience In Every Details For Customized Plugged Graphite Oilless Bushings From Production To Delivery

Low friction. Range of operating temperatures. Freedom of oilless bushings design on flange shape and the size. Excellent corrosion and chemical resistance. This bearing can be used in river or sea water; in liquids where chemical resistance of the metal base and solid lubricant is needed; and in gas where oil supply is difficult. Excellent impact resistance.

Oilless Bushings & Brass Sleeve Bushing Manufacturer

We manufacture bushings for die sets, brass bushing sleeve, metal stamping dies, molds, special machines and all types of heavy equipment. Self-Lubricating Graphite Oilless Bushings are made of solid aluminum bronze and can be ordered with or without self-lubricating graphite. They are available in a wide range of inch and metric sizes, including all NAAMS bushing sizes. And, if a standard bushing does not meet the need, we can economically manufacture a custom oil-free bushing in virtually any size.

Oil-free Slide Bearing Online Sourcing

Bronze Sleeve Bearings, Oilless Metallic Bearings Supplier

Oil-Free Bushings – Oil-Less/Graphite Embedded Bush, Machined Part

Oilless Bushing Size Online Catalog Download, Contact Us Today For A Quote! Exporter and designer of oil-free bushings, graphite bronze bearing, graphite plugged bronze sleeve bushings, oilless bushings. Oilless bushings is a copper-based self-lubricating bearing for heavy load applications into which solid lubricant plugs are embedded. Cylindrical bushes, grooves, oil holes, slots, etc.

Oilless Bushings Manufacturer, Oilless Metal Sliding Materials

We manufacture bushings for die sets, metal stamping dies, molds, special machines and all types of heavy equipment. Self-Lubricating Graphite Oilless Bushings are made of solid aluminum bronze and can be ordered with or without self-lubricating graphite. They are available in a wide range of inch and metric sizes, including all NAAMS bushing sizes. And, if a standard bushing does not meet the need, we can economically manufacture a custom oil-free bushing in virtually any size.

Always self-lubricating, Always oil-less free, Always long-lasting!

Bronzelube Offer Variety Of Bronze Standard Bearings & Flange Bronze Standard Bushings Worldwide, Professional Technology. Low Price. Order Now! Inquiry Us Now. What We Can Offer Our Experience On Bushings & Bearings. Tech Up, Cost Down, Oil-Free Bearing? Find Your Bearings Parts. Oilless Bearings Material: Bronze corrosion in seawater! Shop oilless bushes! From guide bushes crafted from bronze with solid lubricant to oilless metal bushings designed for high-load, low-speed applications, Chinese manufacturers offer a wide array of solutions. These products find extensive use in general industrial machinery and heavy industrial facilities, where they contribute to operational efficiency and longevity of the machinery.

- C95400 aluminum bronze bushings

- C93200 tin bronze bearing rg7

- C86300 high tensile brass bushings, C863 Manganese Bronze

Sed porttitor lectus nibh. Vivamus magna justo, lacinia eget consectetur sed, convallis.

Aluminium Bronze Oilless Bushes– a corrosion resistant metal in sea water

Finished Machined Aluminium Bronze Parts:Bronze corrosion in seawater, The maritime industry places high demands on its self-lubricating copper bushing materials. The high salt content of seawater and ocean currents are just two of the many factors that promote corrosion. However, there is an alloy that can withstand the harsh conditions of the ocean. Aluminum Bronze Bushing!Oil-free bushings, also known as self-lubricating bearings, are specially designed to reduce friction between moving parts without the need for oil-based lubrication. This is achieved through the incorporation of solid lubricants within the bearing material, which are gradually released as the bearing operates. The result is a component that requires less maintenance, lasts longer, and operates more efficiently than traditional bearings.

Driving Efficiency with Oil-Free Bushings: A Closer Look at China’s Self-Lubricating Bearing Manufacturers

Self-lubricating, oil-free bushings are revolutionizing industries by improving efficiency and reducing costs. They eliminate the need for regular lubrication, minimize maintenance, and extend machinery lifespan. China leads in this innovation with its strong manufacturing capabilities. Explore our oilless bushing bearing catalogs or browse them in PDF format!

Plain & Self-Lubricating Oil-free Bearings Supplier

Oilless Metal Sliding Materials, High Quality oil free Bushing with Competitive Price, Suitable for vertical use. Reduces the time of manufacturing and assembling the housing. Self-Lubricated & Maintenance-Free. Inch, metric sizes. Self-lubricating bushes oil free bushing bearing – Wear Plates with graphite. Oilless Bush. Copper Alloy. Straight type. Material Base Copper alloy. Solid lubricantWe Help Grow Your Business Rapidly!Buy Oilless Bush China Direct From Oilless Bush Factories at bronzelube.com. Help Global Buyers Source China Easily. Oilless bushing is called self lubricating bearings, or plain sleeve bearings, its the most popular industrial components for economic price.

Oil Less Bushing Bronze Parts Supplier

Beautifully crafted leather products.

Oilless Bushing, Bronze Parts Manufacturer – Self-lubricating bushes bearing. Oilless Bush. Copper Alloy. Straight type. Material Base Copper alloy ,Solid lubricant. Large Inventory of Bronze Material, Bronze Bushing, and Bronze Flange Bearings. An unrivaled range of plain bearings for all applications in all industries. Whether you are working on a large complex project requiring many different sizes of bearings, or a smaller project using standard size bearings, we have the right solution for you. Technical advice for all your plain bearing requirements. oilless bushing bearings or solid bronze bearings are the cheapest types of slide bearings.

Consisting of oil-free bearing surfaces without rolling elements, they are lightweight, compact, and have a high load-carrying capacity for a wide range of applications. Our extensive range of plain bushing includes dry, lubricated, parallel and flanged. They have very good wear and friction properties under a wide range of load, speed and temperature conditions.

Special Dimension Oil less Bush Email Our Team

Beautifully crafted leather products.

Oilless Bushing, Bronze Parts Manufacturer – Self-lubricating bushes bearing. Oilless Bush. Copper Alloy. Straight type. Material Base Copper alloy ,Solid lubricant. Large Inventory of Bronze Material, Bronze Bushing, and Bronze Flange Bearings. An unrivaled range of plain bearings for all applications in all industries. Whether you are working on a large complex project requiring many different sizes of bearings, or a smaller project using standard size bearings, we have the right solution for you. Technical advice for all your plain bearing requirements. oilless bushing bearings or solid bronze bearings are the cheapest types of slide bearings.

Consisting of oil-free bearing surfaces without rolling elements, they are lightweight, compact, and have a high load-carrying capacity for a wide range of applications. Our extensive range of plain bushing includes dry, lubricated, parallel and flanged. They have very good wear and friction properties under a wide range of load, speed and temperature conditions.

Oil-Free Bearing Supplier – Premium Oilless Bushings for Every Application

Exceptional Customer Service | Register Online Today

We specialize in manufacturing self-lubricating, maintenance-free bearings designed to meet your specific needs.

Oilless Bushings: Your Guide to Choosing the Right Supplier

Oilless bushings, often referred to as dry bushings, are self-lubricating bearings that operate without the need for oil or grease. They are commonly used in various industries, including automotive, electrical, and mechanical systems, due to their durability, low friction, and high performance.

When selecting an oilless bushing supplier, it’s crucial to consider several factors to ensure you get the best product for your requirements. Here’s a guide to help you choose:

1. Quality Assurance

The quality of oilless bushings can differ greatly among suppliers. Choose a supplier known for producing high-quality, reliable products. Look for companies that use premium materials and have stringent quality control procedures to ensure consistency and durability.

2. Proven Experience

Experience is key when selecting an oilless bushing supplier. Look for a supplier with a track record of success, having been in business for several years and producing consistently high-quality products.

3. Customization Options

Depending on your specific application, you may need customized oilless bushings. Select a supplier that offers customization services and can manufacture bushings according to your exact specifications.

4. Cost Considerations

While price is an important factor, it’s essential to balance it with other considerations like quality, experience, and customization. The cheapest option may not always provide the best value, so choose wisely.

5. Lead Time

Ensure your supplier can meet your deadlines by offering short lead times. Timely delivery is critical to avoid delays in your production process.

6. Technical Support

Choose a supplier that provides comprehensive technical support. A knowledgeable team can assist with product selection, troubleshooting, and any questions related to your specific application.

In Summary

Choosing the right oilless bushing supplier is crucial for ensuring high performance and reliability in your applications. By considering factors such as product quality, supplier experience, customization, pricing, lead time, and technical support, you can find the ideal partner for your needs.

What Are Oil-Free Bearings and How Do They Work?

Oil-free bearings are a type of sliding bearing designed to function without the need for traditional lubricants like oil or grease. They are often made from self-lubricating materials such as PTFE, bronze, and graphite, which allow the bearings to reduce friction and maintain high performance without additional lubrication.

These bearings are ideal for vertical applications and can help reduce the time and cost associated with manufacturing and assembling bearing housings. They are used in various industries, including automotive, industrial machinery, and marine systems.

There are several types of sliding bearings based on the lubrication method, including oil-lubricated, grease-lubricated, water-lubricated, gas-lubricated, and solid-lubricated bearings. Oil-free bearings fall under the category of solid-lubricated bearings, where lubrication is provided by materials like graphite or PTFE embedded in the bearing surface.

Types of Oil-Free Bearings

-

Graphite-Plugged Bearings: These bearings are typically made from materials such as copper alloy, carbon steel, and polyacetal resin. They are filled with solid lubrication materials like graphite or PTFE, which transfer to the friction surface during operation to reduce wear and friction.

-

Inlaid Solid Lubrication Bearings: A prime example is the JDB series oil-free bearing, which features a metal substrate like brass, tin bronze, or aluminum bronze. These bearings are embedded with solid lubricants such as graphite or molybdenum disulfide, which provide lubrication in the absence of oil, reducing friction and extending the life of the bearing.

-

Self-Lubricating Bearings: These bearings are made from special self-lubricating materials that eliminate the need for external lubrication. They are often used in applications involving heavy loads and high temperatures, and are suitable for a variety of industries, including manufacturing, marine, and power generation.

-

Flanged and Straight Bushings: These oil-free bushings are available in a range of sizes and are made from solid aluminum bronze, often with self-lubricating graphite embedded to reduce friction. They are ideal for heavy-duty applications and offer long-lasting performance without the need for constant maintenance.

Applications of Oil-Free Bearings

Oil-free bearings are widely used in various industrial applications, such as:

- Continuous Casting Machines

- Rolling Mills

- Injection Molding Machines

- Paper Machines

- Shipbuilding

- Machine Tools

These bearings are designed to handle high loads, resist corrosion, and operate in hostile environments, making them suitable for demanding applications.

Conclusion

Oil-free bearings, including self-lubricating and graphite-plugged varieties, offer a reliable and maintenance-free solution for many industries. By selecting a trusted supplier with experience in producing high-quality oilless bushings, you can ensure that your equipment runs smoothly, efficiently, and without the need for regular lubrication.

Whether you need standard or customized solutions, our team is here to help you find the right oilless bushings for your specific requirements. Explore our range of oil-free bearings and experience the benefits of reduced maintenance and improved performance today!

GRAPHITE BRONZE BUSHING ORDER FROM CHINA

Plug graphite bearings are primarily used in applications that need continual lubrication in hard to reach areas.

Help You Find The Right Oilles Bushes From China

Advanced production oilles bushes , plain bearings, self-lubricating bearings, copper sleeve, graphite copper sleeve, self-lubricating copper sleeve, self-lubricating copper slide plate, oil-free bearings, composite bushing,rolled bronze bearings,bronze sleeve bushing, bronze sliding bearing, bronze bearing professional suppliers.

For detailed Oilless Bushes specifications, check with the electronic catalog

Oilless bearings, also known as oil-free or self-lubricating bearings, are innovative components that combine the strength of metal bearings with the low-friction properties of solid lubricants. These bearings are widely used in various industries due to their ability to operate without external lubrication, reducing maintenance requirements and improving operational efficiency. Below is a detailed overview of oilless bearings, their types, advantages, applications, and ordering options.

What are Oilless Bearings?

Oilless bearings are a type of sleeve bearing that integrates solid lubricants (e.g., graphite, PTFE) into a metal matrix (e.g., bronze, steel). The metal matrix provides structural strength and load-bearing capacity, while the solid lubricant ensures smooth operation and reduces friction.

Types of Oilless Bearings

-

Bronze Graphite Self-Lubricating Bushings:

-

Composition: Bronze alloy with embedded graphite.

-

Properties: High porosity (20-25%) allows for oil retention, providing permanent lubrication.

-

Advantages:

-

No need for external lubrication.

-

Low noise and wear.

-

Long operational life (thousands of hours).

-

-

Applications: Electrical equipment, household appliances, printing machines, machine tools, etc.

-

-

Spherical Bronze Graphite Bushings:

-

Composition: Bronze alloy with graphite, designed for spherical applications.

-

Properties: Self-aligning, low friction, and high load capacity.

-

Advantages:

-

Reduces the risk of scuffing.

-

Suitable for misaligned or oscillating shafts.

-

-

Applications: Heavy machinery, automotive components, and industrial equipment.

-

-

Oil-Free Linear Motion Bushings:

-

Composition: Metal matrix with solid lubricants.

-

Properties: Designed for linear motion systems, providing smooth and precise movement.

-

Advantages:

-

Maintenance-free operation.

-

High precision and durability.

-

-

Applications: Factory automation, assembly automation, and mechanical systems.

-

-

Configurable Oil-Free Bushings and Washers:

-

Composition: Customizable materials and designs.

-

Properties: Tailored to specific load, speed, and environmental conditions.

-

Advantages:

-

Versatile and adaptable to various applications.

-

Short lead times for custom designs.

-

-

Applications: Specialized industrial and mechanical systems.

-

Advantages of Oilless Bearings

-

Maintenance-Free Operation:

-

No need for external lubrication, reducing downtime and maintenance costs.

-

-

Long Service Life:

-

Solid lubricants ensure consistent performance over thousands of hours.

-

-

Low Noise and Vibration:

-

Smooth operation minimizes noise and wear.

-

-

High Load Capacity:

-

Metal matrix provides strength and durability.

-

-

Corrosion Resistance:

-

Suitable for harsh environments.

-

-

Self-Lubricating:

-

Embedded lubricants ensure continuous performance without additional lubrication.

-

Applications of Oilless Bearings

-

Electrical Equipment:

-

Motors, generators, and transformers.

-

-

Household Appliances:

-

Washing machines, refrigerators, and air conditioners.

-

-

Printing Machines:

-

High-precision components requiring low friction.

-

-

Machine Tools:

-

Spindles, slides, and guides.

-

-

Automotive:

-

Suspension systems, steering components, and engine parts.

-

-

Factory Automation:

-

Linear motion systems, robotic arms, and conveyors.

-

-

Heavy Machinery:

-

Construction equipment, agricultural machinery, and industrial presses.

-

Custom Design and Engineering Support

-

Customization: Oilless bearings can be tailored to meet specific requirements, including size, material, and lubrication type.

-

Engineering Support: Expert assistance in selecting the right bearing for your application, ensuring optimal performance and cost-effectiveness.

-

Short Lead Times: Rapid production and delivery of custom-designed bearings.

Ordering Options

-

Online Sourcing:

-

Browse and purchase oilless bearings through the company’s e-Catalog.

-

-

Online Quote:

-

Request a quote for custom-designed bearings based on your specifications.

-

-

Manufacturing to Specifications:

-

Products can be manufactured according to customer requirements, including dimensions, materials, and performance criteria.

-

Conclusion

Oilless bearings are a versatile and reliable solution for a wide range of industrial and mechanical applications. Their self-lubricating properties, combined with high load capacity and low maintenance requirements, make them ideal for demanding environments. By offering custom design, engineering support, and short lead times, your company provides high-performance oilless bearings tailored to meet specific customer needs. Whether for factory automation, automotive systems, or household appliances, oilless bearings ensure smooth, efficient, and long-lasting operation.

Oil-free bearings, particularly metal-based inlaid solid self-lubricating bearings (JDB bearings), are innovative solutions designed to address the challenges of lubrication in harsh operating conditions. These bearings combine the strength of a metal matrix with the self-lubricating properties of embedded solid lubricants, making them ideal for heavy-load, low-speed, and high-temperature applications. Below is a detailed explanation of their features, advantages, applications, and technical principles.

What are Metal-Based Inlaid Solid Self-Lubricating Bearings (JDB Bearings)?

JDB bearings are a type of oil-free bearing that integrates solid lubricants (e.g., graphite, PTFE, or molybdenum disulfide) into a metal matrix (e.g., bronze, steel, or iron). The metal matrix provides structural strength and load-bearing capacity, while the embedded solid lubricants ensure smooth operation and reduce friction without the need for external lubrication.

Key Features of JDB Bearings

-

High Load Capacity:

-

The metal matrix can withstand heavy loads, making these bearings suitable for demanding applications.

-

-

Self-Lubricating:

-

Embedded solid lubricants provide continuous lubrication, reducing friction and wear.

-

-

Impact Resistance:

-

Capable of handling shock loads and vibrations.

-

-

High-Temperature Resistance:

-

Operates effectively in high-temperature environments.

-

-

Corrosion Resistance:

-

Resists corrosion from water, acids, and other harsh chemicals.

-

-

Maintenance-Free:

-

Eliminates the need for external lubrication, reducing maintenance costs and downtime.

-

-

Long Service Life:

-

The embedded lubricants ensure consistent performance over extended periods.

-

Advantages of JDB Bearings

-

Suitable for Harsh Conditions:

-

Ideal for environments with high dust, moisture, or acidic gases (e.g., CO, SO₂).

-

-

Energy and Cost Savings:

-

Reduces the need for oil and grease, lowering energy consumption and operational costs.

-

-

Improved Equipment Uptime:

-

Minimizes wear and damage to components, reducing the frequency of equipment shutdowns.

-

-

Versatility:

-

Can be used in a wide range of applications, from heavy machinery to precision equipment.

-

-

Environmental Benefits:

-

Eliminates the risk of oil leaks and contamination, making them environmentally friendly.

-

Applications of JDB Bearings

-

Metallurgical Industry:

-

Continuous casting machines, rolling mills, and other high-temperature equipment.

-

-

Mining Machinery:

-

Crushers, conveyors, and drilling equipment operating in dusty and abrasive environments.

-

-

Marine and Shipbuilding:

-

Bearings for propellers, rudders, and other components exposed to water and salt.

-

-

Power Generation:

-

Turbines, hydroelectric generators, and steam turbines.

-

-

Injection Molding:

-

High-precision bearings for molds and machinery.

-

-

Automotive Manufacturing:

-

Heavy-load components such as suspension systems and engine parts.

-

-

Cement Production:

-

Bearings for kilns, crushers, and grinding mills.

-

-

Petrochemical Industry:

-

Equipment exposed to corrosive chemicals and high temperatures.

-

Technical Principles of JDB Bearings

-

Metal Matrix:

-

The metal substrate (e.g., bronze, steel, or iron) provides structural strength and load-bearing capacity.

-

-

Embedded Solid Lubricants:

-

Solid lubricants (e.g., graphite, PTFE) are embedded in holes or grooves within the metal matrix.

-

-

Lubrication Mechanism:

-

During operation, friction causes the solid lubricants to transfer to the bearing surface, forming a thin, uniform lubricating film.

-

This film reduces friction and wear, ensuring smooth operation.

-

-

Continuous Lubrication:

-

As the bearing operates, the embedded lubricants are gradually released, providing long-term lubrication without the need for external intervention.

-

Why JDB Bearings are Essential for the Mold Industry

The mold industry requires high-precision, durable, and maintenance-free components to ensure efficient production processes. JDB bearings are particularly well-suited for this industry due to:

-

High Precision:

-

Ensures smooth operation of molds and machinery.

-

-

Low Friction:

-

Reduces wear and tear on molds, extending their lifespan.

-

-

Maintenance-Free Operation:

-

Minimizes downtime and maintenance costs.

-

-

Corrosion Resistance:

-

Withstands exposure to cooling fluids and other chemicals used in mold production.

-

Economic and Social Benefits

-

Cost Savings:

-

Reduces the need for frequent lubrication and replacement of parts.

-

-

Increased Productivity:

-

Minimizes equipment downtime, ensuring continuous operation.

-

-

Environmental Protection:

-

Eliminates the risk of oil leaks and contamination.

-

-

Improved Working Conditions:

-

Reduces the need for manual lubrication in hazardous environments.

-

Conclusion

Metal-based inlaid solid self-lubricating bearings (JDB bearings) are a revolutionary solution for industries operating under harsh conditions. Their unique combination of high load capacity, self-lubrication, and corrosion resistance makes them ideal for applications in metallurgy, mining, marine, power generation, and the mold industry. By eliminating the need for external lubrication and reducing maintenance requirements, JDB bearings offer significant economic and environmental benefits. Their adoption can lead to improved productivity, reduced operational costs, and enhanced equipment reliability, making them a valuable investment for modern industrial applications.

Aluminum Bronze Oilless Bearings: A Corrosion-Resistant Solution for Marine Applications

Aluminum bronze oilless bearings, particularly those made from CuAl10Ni5Fe4 (2.0966) or its equivalent C63000, are highly valued in marine and industrial applications due to their exceptional corrosion resistance, high strength, and self-lubricating properties. These bearings are specifically designed to withstand harsh environments, such as seawater, where corrosion and wear are significant challenges. Below is a detailed overview of aluminum bronze oilless bearings, their properties, advantages, and applications.

Composition and Properties of Aluminum Bronze

Composition

-

Primary Alloying Elements: Copper (Cu), aluminum (Al), nickel (Ni), and iron (Fe).

-

Typical Composition:

-

Aluminum: 9–14%

-

Nickel: 4–6%

-

Iron: 3–5%

-

Copper: Balance

-

Key Properties

-

Corrosion Resistance:

-

Excellent resistance to seawater, brackish water, and other corrosive environments.

-

Forms a passive protective film (brown oxide layer) that heals quickly if damaged.

-

-

High Strength and Hardness:

-

Superior mechanical properties compared to other bronze alloys.

-

Can be further strengthened through heat treatment (quenching and tempering).

-

-

Wear Resistance:

-

Ideal for high-load and high-wear applications.

-

-

Self-Lubricating:

-

Embedded solid lubricants (e.g., graphite) reduce friction and eliminate the need for external lubrication.

-

-

High-Temperature Resistance:

-

Maintains performance in high-temperature environments.

-

-

Low Maintenance:

-

Self-lubricating properties reduce the need for frequent maintenance.

-

Advantages of Aluminum Bronze Oilless Bearings

-

Exceptional Corrosion Resistance:

-

Resists pitting, crevice corrosion, and erosion-corrosion in seawater and other aggressive environments.

-

-

High Load Capacity:

-

Suitable for heavy-load applications, such as marine propulsion systems and industrial machinery.

-

-

Self-Lubricating and Maintenance-Free:

-

Embedded graphite or other solid lubricants ensure smooth operation without external lubrication.

-

-

Long Service Life:

-

Durable and wear-resistant, reducing the need for frequent replacements.

-

-

Versatility:

-

Can be used in a wide range of applications, from marine to industrial and chemical processing.

-

Applications of Aluminum Bronze Oilless Bearings

Marine Industry

-

Propeller Systems:

-

Used in propeller shafts and bearings due to their resistance to seawater corrosion.

-

-

Seawater Piping Systems:

-

Ideal for pumps, valves, flanges, and pipe fittings in desalination plants and offshore platforms.

-

-

Offshore Platforms:

-

Used in equipment exposed to seawater, such as winches, cranes, and drilling systems.

-

Industrial Applications

-

Desalination Plants:

-

Components like pumps, valves, and bearings in seawater desalination systems.

-

-

Chemical Processing:

-

Equipment exposed to corrosive chemicals and high temperatures.

-

-

Power Generation:

-

Bearings and components in turbines and cooling systems.

-

-

Heavy Machinery:

-

High-load applications such as crushers, conveyors, and presses.

-

Other Applications

-

Plant Components:

-

Pumps, valves, and fittings in industrial plants near coastal areas.

-

-

Cooling Systems:

-

Bearings and components in seawater cooling systems for industrial plants.

-

Why Aluminum Bronze is Ideal for Marine Environments

-

Seawater Resistance:

-

The high aluminum content forms a protective oxide layer that resists corrosion from dissolved salts in seawater.

-

-

Erosion and Cavitation Resistance:

-

Withstands the abrasive effects of ocean currents and cavitation in pumps and propellers.

-

-

Low Maintenance:

-

Self-lubricating properties eliminate the need for frequent lubrication, reducing downtime and maintenance costs.

-

-

Aesthetic Durability:

-

The brown oxide layer, while not aesthetically pleasing, provides long-term protection and should not be removed.

-

Technical Specifications

-

Material Standards:

-

CuAl10Ni5Fe4 (2.0966): European standard.

-

C63000: UNS equivalent.

-

-

Mechanical Properties:

-

Tensile Strength: 600–900 MPa

-

Hardness: 160–220 HB

-

Wear Resistance: Excellent

-

-

Temperature Range:

-

Operating Temperature: Up to 400°C (752°F)

-

Conclusion

Aluminum bronze oilless bearings, such as those made from CuAl10Ni5Fe4 or C63000, are a superior choice for marine and industrial applications requiring corrosion resistance, high strength, and low maintenance. Their self-lubricating properties, combined with exceptional wear and corrosion resistance, make them ideal for harsh environments like seawater, desalination plants, and offshore platforms. By choosing aluminum bronze oilless bearings, industries can achieve long-lasting performance, reduced maintenance costs, and improved operational efficiency. These bearings are a testament to the importance of using high-quality materials to overcome the challenges posed by corrosive and high-load environments.

Oil-Free Bearings: The Ultimate Solution for Maintenance-Free, High-Performance Applications

Oil-free bearings, also known as self-lubricating bearings, are innovative components designed to operate without the need for external lubrication. These bearings are ideal for high-load, low-speed applications and harsh environments where traditional lubrication methods are impractical or ineffective. Below is a comprehensive overview of oil-free bearings, their advantages, applications, and why they outperform ordinary graphite bushings and bearings.

What are Oil-Free Bearings?

Oil-free bearings are self-lubricating bushings made from high-strength materials such as bronze, steel, or composite alloys. They are embedded with solid lubricants like graphite, PTFE, or molybdenum disulfide, which provide continuous lubrication during operation. This eliminates the need for external oil or grease, making them maintenance-free and highly reliable.

Key Features of Oil-Free Bearings

-

Self-Lubricating:

-

Embedded solid lubricants ensure smooth operation without the need for external lubrication.

-

-

Maintenance-Free:

-

Reduces downtime and maintenance costs.

-

-

High Load Capacity:

-

Suitable for heavy-load applications.

-

-

Wide Temperature Range:

-

Can operate in extreme temperatures, from -200°C (-400°F) to 400°C (800°F).

-

-

Corrosion Resistance:

-

Resists corrosion in wet, dry, and chemically aggressive environments.

-

-

Low Friction:

-

Reduces energy consumption and wear, extending the lifespan of components.

-

-

Versatility:

-

Can be used in both rotary and linear motion applications.

-

Advantages of Oil-Free Bearings

-

Reduced Costs:

-

Eliminates the need for oil or grease, reducing lubrication costs.

-

-

Increased Productivity:

-

Maintenance-free operation minimizes downtime and improves efficiency.

-

-

Enhanced Performance:

-

Superior wear resistance and low friction ensure long-lasting performance.

-

-

Environmental Benefits:

-

No risk of oil leaks or contamination, making them eco-friendly.

-

-

Customizable:

-

Available in various materials, sizes, and configurations to meet specific application requirements.

-

Applications of Oil-Free Bearings

Oil-free bearings are used in a wide range of industries and applications, including:

Industrial Machinery

-

Lifting Equipment: Cranes, hoists, and elevators.

-

Hydraulic Pumps and Motors: High-load, low-speed systems.

-

Pneumatic Equipment: Compressors and actuators.

-

Textile Machinery: Spinning and weaving machines.

Agricultural Equipment

-

Tractors, harvesters, and irrigation systems.

Medical and Scientific Equipment

-

Precision instruments and devices requiring clean, maintenance-free operation.

Automotive and Transportation

-

Suspension systems, steering components, and heavy-duty vehicles.

Chemical and Processing Industries

-

Pumps, valves, and mixers exposed to corrosive chemicals.

Marine and Offshore

-

Propeller shafts, rudders, and offshore platform equipment.

Why Oil-Free Bearings Outperform Ordinary Graphite Bushings

-

Self-Lubricating Properties:

-

Oil-free bearings have embedded solid lubricants that provide continuous lubrication, whereas ordinary graphite bushings may require external lubrication.

-

-

Higher Load Capacity:

-

Oil-free bearings are made from high-strength materials, making them suitable for heavy-load applications.

-

-

Wider Temperature Range:

-

Can operate in extreme temperatures, unlike ordinary graphite bushings, which may have limited temperature tolerance.

-

-

Lower Maintenance:

-

Oil-free bearings are maintenance-free, while ordinary graphite bushings may require periodic lubrication and maintenance.

-

-

Longer Service Life:

-

The combination of high strength, wear resistance, and self-lubrication ensures a longer lifespan compared to ordinary graphite bushings.

-

Custom Design and Engineering Support

-

Customization: Oil-free bearings can be tailored to meet specific requirements, including size, material, and lubrication type.

-

Engineering Support: Expert assistance in selecting the right bearing for your application, ensuring optimal performance and cost-effectiveness.

-

Short Lead Times: Rapid production and delivery of custom-designed bearings.

Quality Assurance and Global Shipping

-

100% Quality Guaranteed: Rigorous testing ensures that all bearings meet the highest standards of performance and reliability.

-

Worldwide On-Time Shipping: Fast and reliable delivery to customers around the globe.

How to Get Started

-

Browse Our Catalog:

-

Explore our range of oil-free bearings and bushings in our e-Catalog.

-

-

Request a Quote:

-

Fill out our online form to get a customized quote for your specific needs.

-

-

Contact Us:

-

Call or email us for engineering support and assistance in selecting the right product.

-

Conclusion

Oil-free bearings are a game-changer for industries seeking maintenance-free, high-performance solutions for heavy-load and harsh-environment applications. Their self-lubricating properties, combined with exceptional wear resistance and low friction, make them superior to ordinary graphite bushings and bearings. By offering custom design, engineering support, and short lead times, we provide cost-effective, reliable, and high-quality oil-free bearings tailored to meet your specific needs. Whether for industrial machinery, agricultural equipment, or marine applications, oil-free bearings ensure smooth, efficient, and long-lasting operation. Contact us today to learn more about how oil-free bearings can benefit your business!

Maintenance-free bearing and guide bushes, bronze with solid lubricant

Bushing Size

Base Material: Special Brass (SO#50SP2)Self-lubricating Lubricant: Graphite

| SIZE | ID | OD | L |

| SOB 8-12-8 | 8 | 12 | 8 |

| SOB 6-10-12 | 6 | 10 | 12 |

| SOB 8-12-10 | 8 | 12 | 10 |

| SOB 8-12-12 | 8 | 12 | 12 |

| SOB 8-12-15 | 8 | 12 | 15 |

| SOB 10-14-8 | 10 | 14 | 8 |

| SOB 10-14-10 | 10 | 14 | 10 |

| SOB 10-14-12 | 10 | 14 | 12 |

| SOB 10-14-15 | 10 | 14 | 15 |

| SOB 10-14-20 | 10 | 14 | 20 |

| SOB 10-15-10 | 10 | 15 | 10 |

| SOB 12-18-8 | 12 | 18 | 8 |

| SOB 12-18-10 | 12 | 18 | 10 |

| SOB 12-18-12 | 12 | 18 | 12 |

| SOB 12-18-15 | 12 | 18 | 15 |

| SOB 12-18-16 | 12 | 18 | 16 |

| SOB 12-18-19 | 12 | 18 | 19 |

| SOB 12-18-20 | 12 | 18 | 20 |

| SOB 12-18-25 | 12 | 18 | 25 |

| SOB 12-18-30 | 12 | 18 | 30 |

| SOB 13-19-10 | 13 | 19 | 10 |

| SOB 13-19-12 | 13 | 19 | 12 |

| SOB 13-19-15 | 13 | 19 | 15 |

| SOB 13-19-16 | 13 | 19 | 16 |

| SOB 13-19-20 | 13 | 19 | 20 |

| SOB 13-19-25 | 13 | 19 | 25 |

| SOB 14-20-10 | 14 | 20 | 10 |

| SOB 14-20-12 | 14 | 20 | 12 |

| SOB 14-20-15 | 14 | 20 | 15 |

| SOB 14-20-20 | 14 | 20 | 20 |

| SOB 14-20-25 | 14 | 20 | 25 |

| SOB 14-20-30 | 14 | 20 | 30 |

| SOB 15-21-10 | 15 | 21 | 10 |

| SOB 15-21-12 | 15 | 21 | 12 |

| SOB 15-21-15 | 15 | 21 | 15 |

| SOB 15-21-16 | 15 | 21 | 16 |

| SOB 15-21-20 | 15 | 21 | 20 |

| SOB 15-21-25 | 15 | 21 | 25 |

| SOB 15-21-30 | 15 | 21 | 30 |

| SOB 16-22-10 | 16 | 22 | 10 |

| SOB 16-22-12 | 16 | 22 | 12 |

| SOB 16-22-15 | 16 | 22 | 15 |

| SOB 16-22-16 | 16 | 22 | 16 |

| SOB 16-22-19 | 16 | 22 | 19 |

| SOB 16-22-20 | 16 | 22 | 20 |

| SOB 16-22-25 | 16 | 22 | 25 |

| SOB 16-22-30 | 16 | 22 | 30 |

| SOB 16-22-35 | 16 | 22 | 35 |

| SOB 16-22-40 | 16 | 22 | 40 |

| SOB 17-23-15 | 17 | 23 | 15 |

| SOB 18-24-10 | 18 | 24 | 10 |

| SOB 18-24-12 | 18 | 24 | 12 |

| SOB 18-24-15 | 18 | 24 | 15 |

| SOB 18-24-16 | 18 | 24 | 16 |

| SOB 18-24-20 | 18 | 24 | 20 |

| SOB 18-24-25 | 18 | 24 | 25 |

| SOB 18-24-30 | 18 | 24 | 30 |

| SOB 18-24-35 | 18 | 24 | 35 |

| SOB 18-24-40 | 18 | 24 | 40 |

| SOB 19-26-15 | 19 | 26 | 15 |

| SOB 19-26-20 | 19 | 26 | 20 |

| SOB 20-28-10 | 20 | 28 | 10 |

| SOB 20-28-12 | 20 | 28 | 12 |

| SOB 20-28-15 | 20 | 28 | 15 |

| SOB 20-28-16 | 20 | 28 | 16 |

| SOB 20-28-19 | 20 | 28 | 19 |

| SOB 20-28-20 | 20 | 28 | 20 |

| SOB 20-28-25 | 20 | 28 | 25 |

| SOB 20-28-30 | 20 | 28 | 30 |

| SOB 20-28-35 | 20 | 28 | 35 |

| SOB 20-28-40 | 20 | 28 | 40 |

| SOB 20-28-50 | 20 | 28 | 50 |

| SOB 20-30-10 | 20 | 30 | 10 |

| SOB 20-30-12 | 20 | 30 | 12 |

| SOB 20-30-15 | 20 | 30 | 15 |

| SOB 20-30-16 | 20 | 30 | 16 |

| SOB 20-30-20 | 20 | 30 | 20 |

| SOB 20-30-25 | 20 | 30 | 25 |

| SOB 20-30-30 | 20 | 30 | 30 |

| SOB 20-30-35 | 20 | 30 | 35 |

| SOB 20-30-40 | 20 | 30 | 40 |

| SOB 20-30-70 | 20 | 30 | 70 |

| SOB 22-32-12 | 22 | 32 | 12 |

| SOB 22-32-15 | 22 | 32 | 15 |

| SOB 22-32-20 | 22 | 32 | 20 |

| SOB 22-32-25 | 22 | 32 | 25 |

| SOB 25-33-12 | 25 | 33 | 12 |

| SOB 25-33-15 | 25 | 33 | 15 |

| SOB 25-33-16 | 25 | 33 | 16 |

| SOB 25-33-20 | 25 | 33 | 20 |

| SOB 25-33-25 | 25 | 33 | 25 |

| SOB 25-33-30 | 25 | 33 | 30 |

| SOB 25-33-35 | 25 | 33 | 35 |

| SOB 25-33-40 | 25 | 33 | 40 |

| SOB 25-33-50 | 25 | 33 | 50 |

| SOB 25-33-60 | 25 | 33 | 60 |

| SOB 25-35-12 | 25 | 35 | 12 |

| SOB 25-35-15 | 25 | 35 | 15 |

| SOB 25-35-16 | 25 | 35 | 16 |

| SOB 25-35-20 | 25 | 35 | 20 |

Oilless Bearings: The Future of Bearing Technology

As industries continue to evolve and innovate, so does the technology behind the machines that drive them. Bearings are an essential component of many industrial machines, providing support and reducing friction between moving parts. Traditional bearings rely on lubrication to reduce friction, but with advancements in material science, a new generation of bearings has emerged: oilless bearings.

What are Oilless Bearings?

Oilless bearings, also known as self-lubricating bearings, are a type of bearing that does not require external lubrication to operate smoothly. Instead, they are made of materials that inherently reduce friction, eliminating the need for additional lubrication. This makes them an ideal choice for machines that operate in harsh environments or where lubrication is difficult or impossible.

Benefits of Oilless Bearings

Oilless bearings offer several advantages over traditional lubricated bearings, including:

- Reduced Maintenance: Because oilless bearings do not require external lubrication, they require less maintenance than traditional bearings. This can save time and money over the lifespan of a machine.

- Longer Lifespan: Oilless bearings are designed to last longer than traditional bearings, reducing the frequency of replacements and associated downtime.

- Increased Durability: Oilless bearings are made of materials that are more durable than traditional bearing materials, allowing them to withstand higher loads and operate in harsher environments.

- Environmentally Friendly: Oilless bearings eliminate the need for external lubrication, reducing the amount of oil and grease that can leak into the environment.

Applications of Oilless Bearings

Oilless bearings are used in a wide range of industrial applications, including:

- Food and Beverage: Oilless bearings are commonly used in food and beverage processing equipment because they eliminate the risk of contamination from external lubricants.

- Medical Equipment: Oilless bearings are ideal for medical equipment because they are self-lubricating and reduce the risk of contamination.

- Aerospace: Oilless bearings are used in aerospace applications because they are lightweight and durable, making them ideal for high-performance applications.

- Marine: Oilless bearings are commonly used in marine applications because they can withstand harsh marine environments without the need for external lubrication.

Oilless bearings are a game-changing technology that offers numerous advantages over traditional lubricated bearings. Their inherent friction-reducing properties, combined with increased durability and reduced maintenance, make them an ideal choice for a wide range of industrial applications. As industries continue to evolve, it’s clear that oilless bearings will play a crucial role in shaping the future of bearing technology.

Bronze Sliding Bearing With Solid Lubricant Insert and Flange Bushing

Graphite is one of the three isomers of the chemical element carbon; the other two are diamond and amorphous carbon. Graphite crystallizes in a hexagonal system. Carbon atoms are tightly bound together in the form of flakes. Due to the weak bonding between the flakes, graphite shows a low shear strength under friction. Therefore, it can be used as a solid lubricant and has become one of the traditional and main solid lubricating materials.

Oilless Metal Sliding Materials Standard Components for Sliding Material

| Oil-free Bush Material | ||||||

| Oil-free Bush Alloy material standard | CODE | CuZn25Al5Fe3Mn3 | CuAl9Fe4Ni4Mn2 | CuSn5Pb5Zn5 | GCr15 | GB5675-85HT250 |

| GB1776-87 | ||||||

| GCuZn25Al5Fe3Mn3 | CuAl10Fe5Ni5 | QSn5-5-5 | B1 | 185Gr250 | ||

| ISO1338 | ||||||

| DIN1709G-CuZn25A15/2.0598 | DIN17656 | DIN1705 | 100Cr16 | DIN17007 | ||

| DIN | GB-CuAL9Ni/2.1096 | G-CuSn5Znpb/2.1096 | GG25/0.6025 | |||

| H5102 CAC304 | H5114 CAC703 | H5111 CAC406 | SUJ2 | FC250 | ||

| JIS | ||||||

| B30-92 C86300 | B30-92 C95800 | B30-92 C83600 | E52100 | ASTM | ||

| ASTM/UNS | Class40 | |||||

| Oil-Free Bush Chemical composition of alloy materials | Cu(%) | Rest | Rest | Rest | * | * |

| Sn(%) | * | * | 4.0~6.0 | * | * | |

| Zn(%) | 22.0~28.0 | * | 4.0~6.0 | * | * | |

| Ni(%) | * | 4.0-5.0 | * | * | * | |

| Al(%) | 5.0~7.0 | 8.5-9.5 | * | * | * | |

| Fe(%) | 2.5~4.0 | 3.0-4.5 | * | Rest | Rest | |

| Mn(%) | 2.5~5.0 | 0.8-1.5 | * | 0.20-0.40 | 0.905-1.3 | |

| Cr(%) | * | * | * | 1.30-1.65 | * | |

| C(%) | * | * | * | 0.95-1.05 | 2.5-4.0 | |

| Si(%) | * | * | * | 0.15-0.35 | 1.0-1.3 | |

| Pb(%) | * | * | 4.0~6.0 | * | * | |

Oilless Metal Sliding Materials

Oil-Free Bushings, Oilless Washer for industrial applications. bronzelube.com offers free CAD downloads, short lead times, competitive pricing, and small minimum order quantity.

| Oilless Metal Sliding Materials | Product name |

| Bush | |

| Straight type | SOB |

| Bush | |

| Straight, Thin type | SOBU |

| Bush | |

| Straight type for Under Water | SOBM |

| Insulated Bushings/Washers | IB,IW |

| Bush | |

| Flange type | SOBF |

| Bush | |

| Flange, Thin type | SOBFU |

| Thrust Bush | |

| I.D. E7, O.D. r6 type | SOSB |

| Thrust Bush | |

| I.D. F7, O.D. m6 type | SOBB |

| Thrust Bush | |

| Split bushing | SOBBD |

| Washer | SOBW,SOBWN |

| Bush | |

| Straight, Bronze Castings type | SOBC |

| Spherical Bush | SOBS |

| Spherical Bush Set Standard type, Strong type | MTGL/MTGR,MTGHL/MTGHR |

| Blank Material for Bushing | S30 |

| Slide Plate | |

| Bronze, Thickness 20mm | SESW,SESWT |

| Slide Plate | |

| Bronze, Thickness 10mm | TWP,TWPT |

| Slide Plate | |

| Bronze, Thickness 5mm | UWP |

| Slide Plate | |

| Bronze, Thickness 10mm | SOLP |

| Slide Plate | |

| Bronze, Thickness 10mm | SOML |

| Slide Plate | |

| Bronze, Blank type | FPLB |

| Slide Plate | |

| Bronze, High Pressure type Thickness 10mm | TLP |

| Slide Plate | |

| FC, Thickness 20mm | SESF,SESFT |

| Slide Plate | |

| Steel, Thickness 20mm | FRP |

| Slide Plate | |

| Steel, Thickness 10mm | TSP |

| Slide Plate | |

| Copper Powder Sintered, Thickness20mm | SOX,SOXT |

| Slide Plate | |

| Copper Powder Sintered, Thickness10mm | TWX,TWXT |

| Slide Guide | |

| Bronze L-Shaped type | SGLDW |

| Slide Guide | |

| Bronze T-Shaped type | TGLWN |

| Slide Guide | |

| Bronze L-Shaped type | SGLXS |

| Slide Guide | |

| Bronze L-Shaped Blank type | SGLX |

| Slide Guide | |

| Bronze L-Shaped type | SOL |

Maintenance free bearing and guide bushes, bronze with solid lubricant, graphite oilless bushes

Oilless Bushes Price and delivery time on request

Description

Graphite Oilless Bushes made of extra hard and resistant bronze with built-in self-lubricating graphite caps for maintenance-free operation. When it comes to high loads and small movements where lubrication is difficult to implement, this Graphite Oilless Bushes is an excellent solution. Graphite plugs cover approximately 25-30% of the Graphite Oilless Bushes surface and are positioned so that the entire Oilless Bushes bearing surface is always lubricated. Graphite Oilless Bushes are available in many designs and can also be manufactured in other alloys to meet specific application needs.

Feature

- Periodic lubrication is not required.

- Anti-seizure properties. It can work in the absence of lubrication / lubrication faults.

- Exceptional wear resistance.

- Excellent incorporability of foreign particles.

- Reduction of the noise level.

- It can also be used at high temperatures.

- Suitable for high loads and high speeds.

- The products are not contaminated with oil.

- Cost effective.

- It can be replaced for sintered bronze

- Reduction of management costs.

- Reduction of maintenance costs.

- Compact design.

- Longer working life.

- Remarkable resistance to corrosion and chemical attacks.

Self-Lubricating Oilless range of Bushes, Bush Bearings, Flanged, Liners & Wear Plates, etc

Bearing forms available in standard dimensions

- Cylindrical bushes

- Flanged bushes

- Thrust washers

- Flanged washers

- Sliding plates

Metric bearings and imperial bushes on request: standard bush shapes in special dimensions, half bushes, special shapes by stamping or deep drawing, customer-specific bush designs

Choose Your Graphite Oilless Bushes Style

Self Lubricating Bushing – High-Quality Factory Oilless Bushes Standard slide bearing

Oilless Bushes Characteristics

– Maintenance free (self-lubricating)

– Suitable for heavy duty applications

– Resists extreme temperatures

– Long lifespan

Oilless Bushes Technical Data

| Base Material: | Special Brass(SO#50SP2) |

| Self-lubricating: | Yes |

| Lubricant: | Graphite |

| Surface Pressure P: | 100 N/mm² |

| Sliding speed v: | 30 m/min |

| PV value: | 200 N/mm² x m/min |

| Operating temperature: | -50°C / +200°C (max. 300°C) |

| Friction coefficient: | 0,07 |

Oilless Bushes Physical properties

| Specific gravity | Hardness | Elongation | Tensile Strength | Linear Expansion Coefficient

×10 -5 /℃ |

| 7.9 | 210 or more | 12 or more | 755 or more | 1.9 |

Welcome to Bronzelube.com

Self-Lubricating Oilless Bushes Graphite Plugged Bronze Sleeve Bushings Now Available Online

Graphite oilless bushes are a substrate in carbon steel, bronze powder, PTFE, fibers and other materials through a special process for the production of self-lubricating products, with the characteristics of environmental protection.

Material

- Base Copper alloy

- Solid lubricant

Structure

1.Solid lubrication film

2.Solid lubricant

3.Copper alloy substrate

Replacement “SOB”oilless bushes (e.g. Inner diameter d 8mm×Outer diameter D 12mm ×Length L 8mm)

Tolerance

d8 :General use (high load)

e7 :General use (light load)

f7 :High precision

It is written the oilless bushes service range, the test data, and the standard size table, etc.

Oilless bushes feature

1. Oil supply device, oil hole, oil groove

2. Reduction of operating costs

3. Shortened design time

4. Recovery and environmental protection of the lubricant

Explore our extensive Oilles Bushes range of to suit all applications.

- Oilles Bushes with tie rods for injection molding machines.

- Oilles Bushes for use at high temperatures, including iron and manufacturing machinery.

- Oilles Bushes for automotive production line.

- Armrests Oilles Bushes for driving blades.

- Activate / deactivate Bush bearings.

- Heavy engineering applications.

- Mining machinery.

- Earth moving and construction machinery.

- Cranes and transport systems.

- Pin bearings for oil-free chains.

- Fulcrum Oilles Bushes for table lifts.

- Oilles Bushes for pulleys for cranes, etc.

- Bushes of dam door and water gate.

- Oilles Bushes for underwater use, e.g. Guide Vane Bearings of water wheels.

- Oilles Bushes for high, dusty and difficult temperatures.

- Oilles Bushes Bearings for nuclear power plants.

- Oilles Bushes Bearings for machine tools.

- Large support Oilles Bushes for bridges.

- Carriage axle bearings and radiator Oilles Bushes bearings.

- Oilles Bushes bearings for the cement industry.

- Oilles Bushes Bearings to be used under high load, low speed and self-lubricating conditions.

- Underwater bearings are used as vane bearings in a turbine

- Oilles Bushes Bearings for use in strong radioactive environments, e.g. Nuclear power plant

- Hydraulic steel structures,Offshore industry shipbuilding Power, plants and reactors, Metallurgical plants, Construction of bridges, pipelines, etc.

- Where thermal expansion should be absorbed.

Graphite Bronze Material Oilless Guide Bushes

Buy Oilless Bushes online bronzelube.com

Designed to be self-lubricating, wear-resistant, and maintenance-free, buy oilless bushes directly from china at Excellent price today!

Sliding Partners for Oilless Bushes and Plates

The most compatible sliding partners for Oilless Bushes and Plates are gas-nitrated or hardened steel alloys with a hardness greater than 35 HRC. To achieve optimal sliding behavior, it is crucial that the hardness difference between the bush or plate and the sliding partner is at least 100 HB. Additionally, the surface roughness of the sliding partner should be maintained between Rz = 3 to 6.3 µm, achieved through grinding.

Providing Custom Solutions, Catalog Available, ISO 9001:2008 Certified Company

STRAIGHT & FLANGE TYPE

Oilless Bush. Copper Alloy. Straight type. Material Base Copper alloy . Solid lubricant. Lubricant Type. Lubricating Bushes

OILLESS SLEEVE BEARING

| OILLESS SLEEVE BEARING BUSHING ID 80MM (ID★OD•LENGTH) | |||||

| 80*90*30 | 80*95*25 | 80*95*75 | 80*96*20 | 80*100*25 | 80*100*75 |

| 80*90*40 | 80*95*30 | 80*95*80 | 80*96*30 | 80*100*30 | 80*100*80 |

| 80*90*50 | 80*95*35 | 80*95*90 | 80*96*40 | 80*100*35 | 80*100*90 |

| 80*90*55 | 80*95*40 | 80*95*95 | 80*96*50 | 80*100*40 | 80*100*100 |

| 80*90*60 | 80*95*50 | 80*95*100 | 80*96*60 | 80*100*45 | 80*100*120 |

| 80*90*70 | 80*95*55 | 80*95*110 | 80*96*70 | 80*100*50 | 80*100*140 |

| 80*90*80 | 80*95*60 | 80*95*120 | 80*96*80 | 80*100*55 | 80*100*150 |

| 80*90*90 | 80*95*65 | 80*95*150 | 80*96*90 | 80*100*60 | 80*100*160 |

| 80*90*95 | 80*95*70 | 80*96*100 | 80*100*70 | ||

| 80*90*100 | 80*96*120 | ||||

| 80*90*120 | 80*96*130 | ||||

| 80*90*140 | 80*96*150 | ||||

| 80*90*150 | |||||

| 80*90*214 | |||||

| OILLESS SLEEVE BEARING BUSHING ID 85MM (ID*OD•LENGTH) | |||||

| 85*95*40 | 85*95*70 | 85*100*30 | 85*100*70 | 85*105*40 | 85*105*80 |

| 85*95*50 | 85*95*80 | 85*100*35 | 85*100*80 | 85*105*50 | 85*105*100 |

| 85*95*55 | 85*95*100 | 85*100*40 | 85*100*90 | 85*105*60 | 85*105*119 |

| 85*95*60 | 85*100*50 | 85*100*100 | 85*105*70 | 85*105*120 | |

| 85*100*60 | 85*105*75 | 85*105*160 | |||

| OILLESS SLEEVE BEARING BUSHING ID90MM (ID*OD*LENGTH) | |||||

| 90*100*30 | 90*100*80 | 90*105*40 | 90*105*80 | 90*110*30 | 90*110*90 |

| 90*100*40 | 90*100*90 | 90*105*50 | 90*105*90 | 90*110*40 | 90*110*100 |

| 90*100*50 | 90*100*95 | 90*105*60 | 90*105*100 | 90*110*50 | 90*110*110 |

| 90*100*60 | 90*100*100 | 90*105*70 | 90*105*120 | 90*110*60 | 90*110*120 |

| 90*100*70 | 90*100*120 | 90*105*75 | 90*105*150 | 90*110*70 | 90*110*130 |