Bronze Bushing For Combine Harvesters

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Bronze Bushing For Combine Harvesters

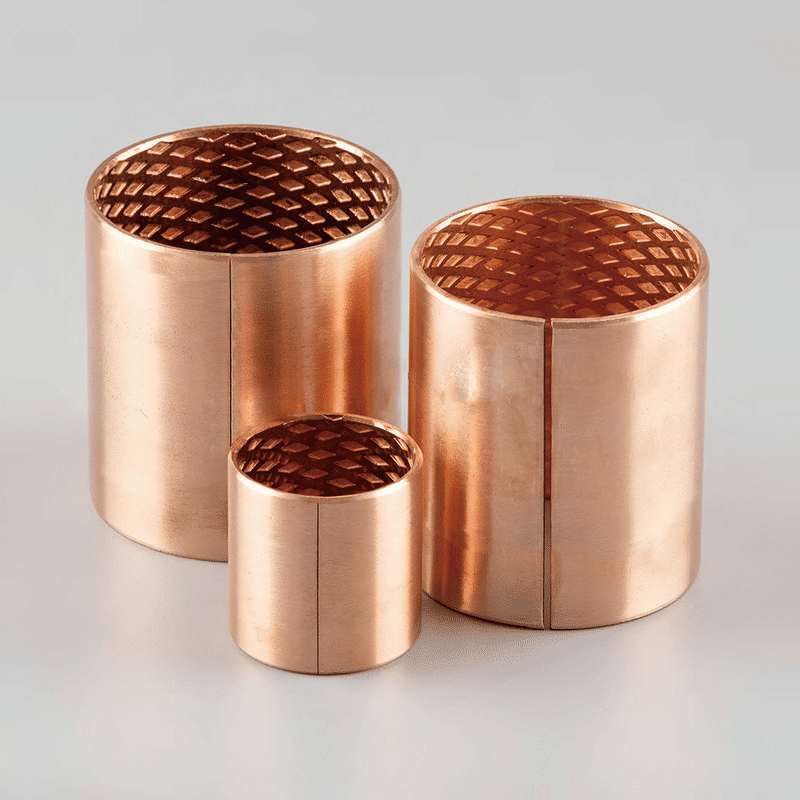

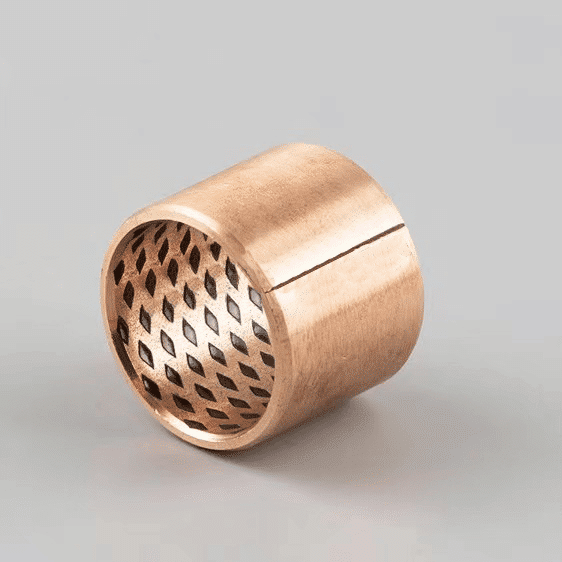

Wrapped Bronze Bearings Made Of CuSn8

Combine harvesters are impressive engineering achievements in agricultural machinery. At the core of these complex machines are numerous moving parts, each carefully designed for optimal performance and durability. Among these are the crucial bronze bushings; specifically, the CuSn8 bronze bearings that ensure reliable and lasting rotational motion in demanding agricultural conditions.

The CuSn8 material

The CuSn8 material in these bearings provides several benefits: copper ensures good thermal conductivity and corrosion resistance, while tin enhances hardness and wear resistance.

CuSn8 Bronze Bushing

CuSn8’s properties make it an ideal choice for applications involving heavy loads, vibrations, and harsh environments.

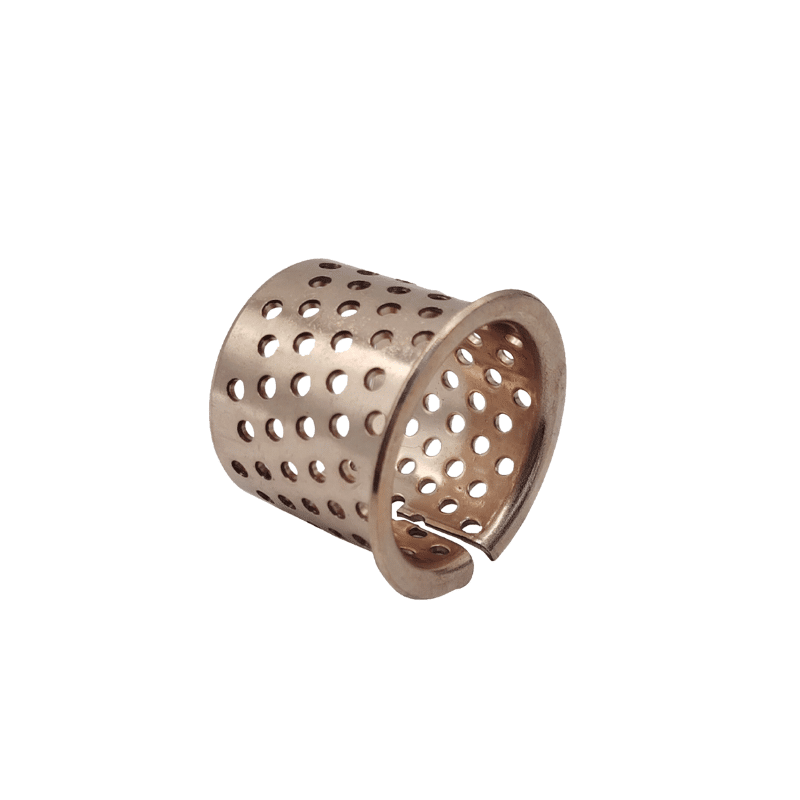

wrapped bronze bearings

Wrapped bronze bearings are utilized in combine harvesters for components like the rotor shaft, cutter bar, and auger, ensuring smooth and reliable operation under heavy loads and continuous use.

Industrial Efficiency of Bronze Bushings in Combine Harvesters: An Overview of Specifications and Applications

specializing in truck food cuisines

Bronze bushings, particularly those used in heavy-duty machinery like combine harvesters, enhance performance and efficiency. They ensure smooth operation, reduce wear and tear, and improve reliability with lower maintenance requirements. CuSn8 bronze bearings are crucial for the performance and durability of combine harvesters, as they withstand harsh conditions, resist wear and corrosion, and contribute to overall efficiency.

CuSn8 is a bronze alloy mainly made of copper (Cu) and tin (Sn), along with trace elements.

A Wrapped Bronze Bearing of CuSn8 for combine harvesters is a specialized bearing used in agricultural machinery.

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.