Special Bronze Alloys

We specialize in high-performance bronze alloys and high-tensile brasses tailored to demanding applications, meeting client requirements and international standards. Additionally, we produce custom bronze alloys or high-tensile brasses upon request, adhering to any specified standard.

Here’s a breakdown of how your offerings align with the mentioned industries:

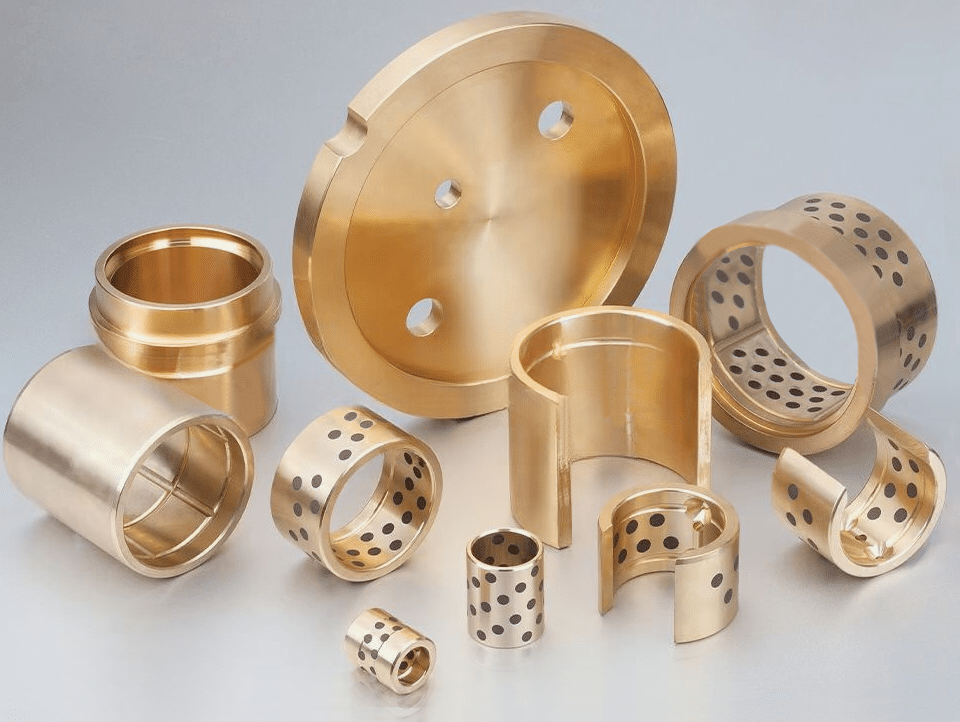

Special Bronze Alloys for Bearings and Bushings

Bronze alloys are widely used in bearings and bushings due to their excellent wear resistance, low friction, and ability to withstand high loads. Your alloys likely include:

- Phosphor Bronze (e.g., C51000, C52100): Known for high strength, fatigue resistance, and corrosion resistance, ideal for heavy-duty bearings.

- Aluminum Bronze (e.g., C95400, C95500): Offers exceptional corrosion resistance and high strength, suitable for marine and harsh environments.

- Leaded Bronze (e.g., C93200, C93700): Provides superior machinability and anti-seizure properties, perfect for bushings and low-speed bearings.

Applications

- Moulds for Glass or Embossing:

- Bronze alloys with high thermal conductivity and resistance to thermal fatigue are ideal for glass moulds.

- Alloys like Beryllium Copper (e.g., C17200) or Aluminum Bronze can withstand high temperatures and repeated thermal cycling.

- Marine Accessories:

- Aluminum Bronze and Nickel-Aluminum Bronze (e.g., C63000) are excellent for marine environments due to their resistance to saltwater corrosion and biofouling.

- Applications include propellers, pumps, and underwater fittings.

- Valve and Terminal Components:

- Phosphor Bronze and Leaded Bronze are commonly used for valve seats, stems, and bushings due to their durability and corrosion resistance.

- These alloys ensure smooth operation and longevity in high-pressure and high-temperature environments.

Key Features of Your Bronze Alloys

- Wear Resistance: Essential for bearings and bushings to reduce maintenance and extend lifespan.

- Corrosion Resistance: Critical for marine and chemical environments.

- Thermal Conductivity: Important for glass moulds and high-temperature applications.

- Machinability: Ensures ease of manufacturing complex components.

Why Choose Your Alloys?

- Tailored compositions for specific applications.

- Proven performance in demanding industries.

- High-quality standards and reliability.

If you’d like, I can help you craft a more detailed product description or marketing material to highlight these features for your target audience. Let me know!

A Guide to Different Types of Bronze Alloys

A Comprehensive Guide to Bronze Alloys and Special Variants. This guide explores various bronze alloys, highlighting their unique characteristics and properties, with particular emphasis on special bronze alloy types.

Made-To-Order Special Alloy Bronze Sleeve Bushing

Custom alloy bronze sleeve bushings are designed for specialized applications, crafted from durable materials for high quality.

Custom Bronze Alloy Bearing, Are you interested in our products?

Special bronze alloys are engineered to meet specific performance requirements in various applications, particularly in bearings. These alloys often combine copper with other elements to enhance properties such as strength, wear resistance, corrosion resistance, and low friction. Here are some notable bronze alloys used in bearing applications:

1. Phosphor Bronze (Tin Bronze)

-

Composition: Copper (Cu) + Tin (Sn) + Phosphorus (P)

-

Properties: High strength, excellent wear resistance, good fatigue resistance, and corrosion resistance.

-

Applications: Widely used in bushings, bearings, and thrust washers, especially in high-load and low-speed applications.

2. Aluminum Bronze

-

Composition: Copper (Cu) + Aluminum (Al) + Iron (Fe) + Nickel (Ni)

-

Properties: High strength, excellent corrosion resistance (especially in seawater), good wear resistance, and high fatigue strength.

-

Applications: Bearings and bushings in marine environments, heavy-duty industrial applications, and aerospace components.

3. Lead Bronze

-

Composition: Copper (Cu) + Tin (Sn) + Lead (Pb)

-

Properties: Good lubricity, low friction, and excellent conformability. The lead content provides self-lubricating properties.

-

Applications: Bearings in automotive engines, heavy machinery, and other applications where lubrication is critical.

4. Silicon Bronze

-

Composition: Copper (Cu) + Silicon (Si) + Zinc (Zn) + Manganese (Mn)

-

Properties: Good strength, corrosion resistance, and wear resistance. Silicon bronze is also known for its ease of casting and machining.

-

Applications: Bearings, bushings, and other components in corrosive environments, such as marine and chemical industries.

5. Manganese Bronze

-

Composition: Copper (Cu) + Zinc (Zn) + Manganese (Mn) + Aluminum (Al)

-

Properties: High strength, good wear resistance, and excellent load-bearing capacity. Manganese bronze is also known for its toughness and durability.

-

Applications: Heavy-duty bearings, gears, and other components in industrial machinery and automotive applications.

6. Beryllium Bronze (Beryllium Copper)

-

Composition: Copper (Cu) + Beryllium (Be) + Cobalt (Co) or Nickel (Ni)

-

Properties: High strength, excellent fatigue resistance, good thermal and electrical conductivity, and corrosion resistance. Beryllium bronze can be heat-treated to achieve very high hardness.

-

Applications: Precision bearings, springs, and other components in aerospace, automotive, and electronic industries.

7. Nickel Aluminum Bronze

-

Composition: Copper (Cu) + Aluminum (Al) + Nickel (Ni) + Iron (Fe)

-

Properties: High strength, excellent corrosion resistance (especially in seawater), good wear resistance, and high fatigue strength.

-

Applications: Bearings, bushings, and other components in marine environments, heavy-duty industrial applications, and aerospace components.

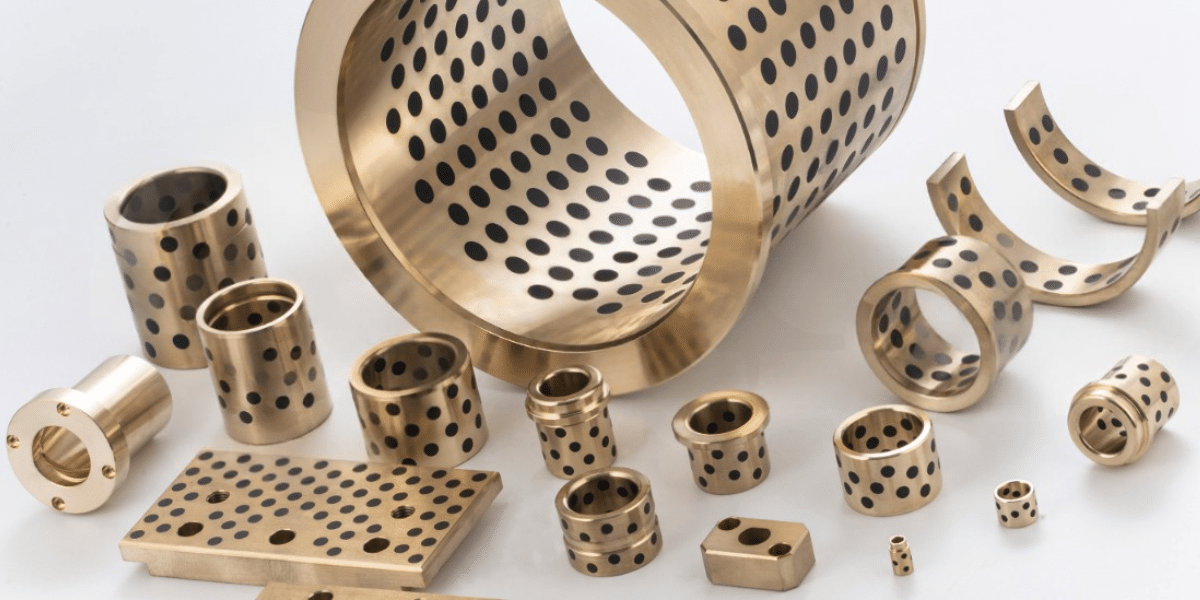

8. Graphite Bronze

-

Composition: Copper (Cu) + Tin (Sn) + Graphite (C)

-

Properties: Self-lubricating, low friction, and good wear resistance. The graphite content provides lubrication, reducing the need for external lubricants.

-

Applications: Bearings and bushings in applications where lubrication is difficult or where maintenance-free operation is desired.

Selection Criteria for Bronze Alloys in Bearings:

-

Load Capacity: The alloy must withstand the expected load without excessive deformation or wear.

-

Speed: Some alloys perform better at high speeds, while others are suited for low-speed applications.

-

Environment: Corrosion resistance is crucial in marine or chemically aggressive environments.

-

Lubrication: Self-lubricating alloys are preferred in applications where regular lubrication is impractical.

-

Temperature: The alloy should maintain its properties at the operating temperature range.

Bronze Alloys according to ASTM B505,

ASTM B271 y ASTM B22

various ASTM B505 copper alloys, closest bronze alloys, the type of alloy, and additional details. Here’s a breakdown of the information:

-

ASTM B505 Alloy: This column lists the specific copper alloy designation under the ASTM B505 standard.

-

Closest Bronze Alloys: This column provides the closest equivalent alloy from or other similar designations.

-

Closest Alloys: This column lists the closest equivalent alloys, often including CDA (Copper Development Association) designations.

-

Type of Alloy: This column categorizes the alloy into types such as Tin bronzes, High tensile brasses, Lead bronzes, and Aluminium Bronzes.

-

See Detail: This column indicates that more detailed information can be found elsewhere, likely in a detailed specification sheet or database.

Summary of Alloy Types:

-

Tin Bronzes: These alloys primarily consist of copper with tin as the main alloying element, often with additional elements like zinc and lead. Examples include C83600, C84400, C90300, C90500, C90700, C92200, C92700, and C93200.

-

High Tensile Brasses: These are copper-zinc alloys with additional elements like manganese, aluminum, and iron to enhance strength. Examples include C86200 and C86300.

-

Lead Bronzes: These alloys contain lead in addition to tin and copper, providing good machinability and wear resistance. Examples include C93600, C93700, C93800, C93900, and C94100.

-

Aluminium Bronzes: These alloys contain aluminum as the primary alloying element, offering high strength and corrosion resistance. Examples include C95200, C95400, C95500, C95520, C95800, and C95900.

Notable Alloys:

-

C83600 (C836 / CDA836): A tin bronze with good casting properties and corrosion resistance.

-

C86200 (C862 / CDA862): A high tensile brass with excellent strength and wear resistance.

-

C93200 (C932 / CDA932): A tin bronze with lead, offering good machinability and bearing properties.

-

C95200 (C952 / CDA952): An aluminium bronze with high strength and excellent corrosion resistance.

The table you provided lists various ASTM B271 copper alloys, their closest bronze Alloys equivalents, the closest general alloy types, and the type of alloy (e.g., tin bronzes, lead bronzes, aluminium bronzes). Below is a summary of the information:

| ASTM B271 Alloy | Closest Alloys | Type of Alloy | ||

|---|---|---|---|---|

| C83600 | CC491K – CuSn5ZnPb5-C | Tin bronzes | ||

| C84400 | CC490K – CuSn3Zn8Pb5-C | Tin bronzes | ||

| C86200 | CC764S – CuZn34Mn3Al2Fe1-C | High tensile brasses | ||

| C90300 | – | Tin bronzes | ||

| C90500 | – | Tin bronzes | ||

| C92200 | – | Tin bronzes | ||

| C93200 | CC493K – CuSn7ZnPb7 | Tin bronzes | ||

| C93600 | – | Lead bronzes | ||

| C93700 | CC495K – CuSn10Pb10-C | Lead bronzes | ||

| C93800 | CC496K – CuSn7Pb15-C | Lead bronzes | ||

| C95200 | CC331G – CuAl10Fe2-C | Aluminium Bronzes | ||

| C95400 | – | Aluminium Bronzes | ||

| C95500 | CC333G – CuAl10Fe5Ni5-C | Aluminium Bronzes | ||

| C95800 | – | Aluminium Bronzes | ||

| C95900 | – | – | Aluminium Bronzes |

Key Observations:

-

Tin Bronzes: Alloys like C83600, C84400, C90300, C90500, C92200, and C93200 fall under this category. They are primarily copper alloys with tin as the main alloying element, often with additions of zinc and lead.

-

Lead Bronzes: Alloys such as C93600, C93700, and C93800 are lead bronzes, which contain significant amounts of lead along with tin and copper.

-

Aluminium Bronzes: Alloys like C95200, C95400, C95500, C95800, and C95900 are aluminium bronzes, which are copper alloys with aluminium as the primary alloying element, often with additions of iron, nickel, or manganese.

-

High Tensile Brasses: C86200 is a high tensile brass, which is a copper-zinc alloy with additional elements like manganese, aluminium, and iron to enhance strength.

If you need more detailed information about any specific alloy or its properties, feel free to ask!

ASTM B22 specifies standards for bronze alloys used in the manufacturing of bearings and bushings. The alloys listed in your table are commonly used for such applications due to their excellent wear resistance, strength, and corrosion resistance. Below is a brief overview of the alloys mentioned:

-

C86300 (High Tensile Brasses):

-

Composition: Primarily copper, zinc, and small amounts of manganese, iron, and aluminum.

-

Properties: High strength, good wear resistance, and excellent machinability.

-

Applications: Suitable for heavy-duty applications such as gears, bearings, and bushings.

-

-

C90500 (Aluminium Bronzes):

-

Composition: Copper with aluminum as the primary alloying element, often with small amounts of iron and nickel.

-

Properties: High strength, excellent corrosion resistance, and good wear resistance.

-

Applications: Used in marine environments, heavy-duty bushings, and bearings.

-

-

C91100 (Tin Bronzes):

-

Composition: Copper with tin as the primary alloying element, often with small amounts of phosphorus.

-

Properties: Good strength, excellent wear resistance, and good corrosion resistance.

-

Applications: Commonly used in bushings, bearings, and wear plates.

-

-

C93700 (Lead Bronzes):

-

Composition: Copper with lead and tin as the primary alloying elements.

-

Properties: Excellent machinability, good wear resistance, and good load-bearing capacity.

-

Applications: Suitable for bushings, bearings, and other applications requiring good lubrication properties.

-

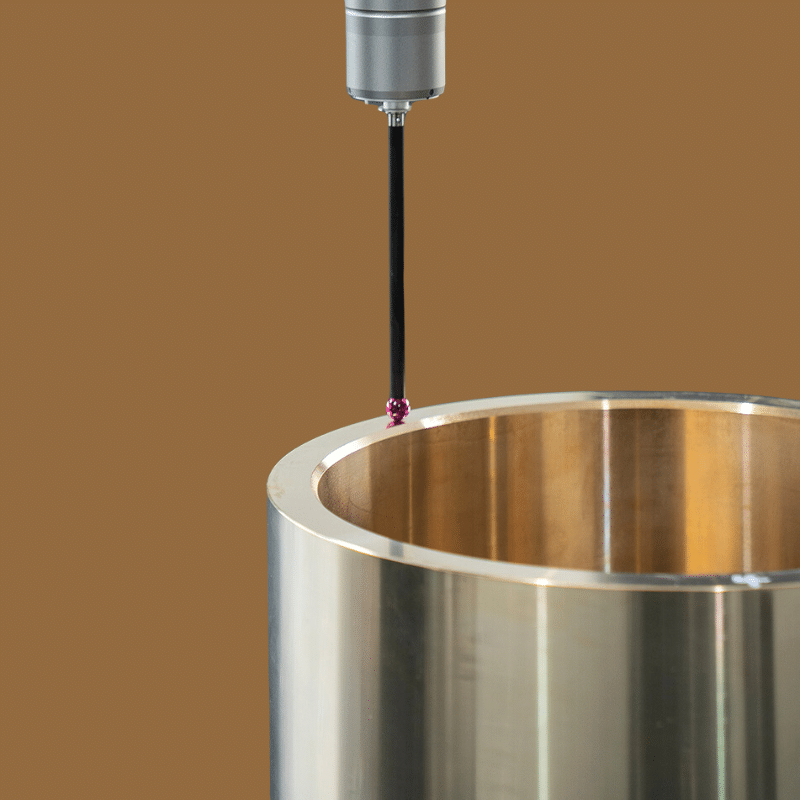

Geometric Shapes and Sizes:

-

Shapes: These alloys can be supplied in various forms such as rods, bars, tubes, and custom shapes.

-

Sizes: Available in a wide range of sizes to meet specific application requirements.

Applications:

-

Bearings and Bushings: These alloys are particularly suited for applications requiring high load capacity, wear resistance, and durability.

-

Industrial Machinery: Used in gears, valves, and other components subjected to high stress and wear.

-

Marine Applications: Due to their excellent corrosion resistance, these alloys are ideal for marine environments.

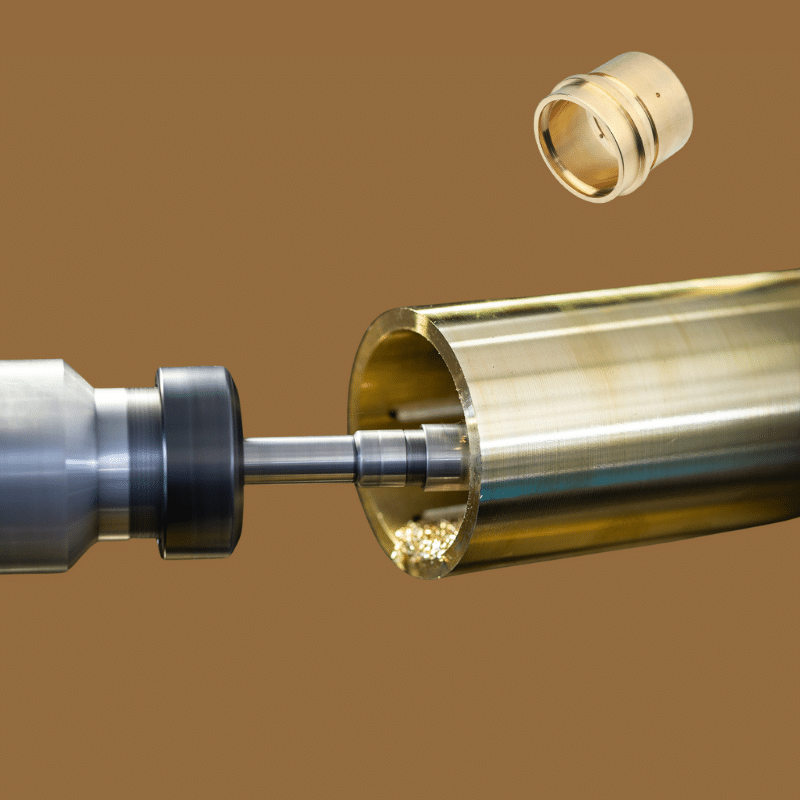

Customization:

-

Machining: These alloys can be machined to precise specifications.

-

Casting: Available in cast forms for complex shapes and large components.

When selecting a bronze alloy for a specific application, it is important to consider factors such as load capacity, operating environment, and required mechanical properties. The alloys listed above offer a range of options to meet diverse industrial needs.