Circular Sizing Plates

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

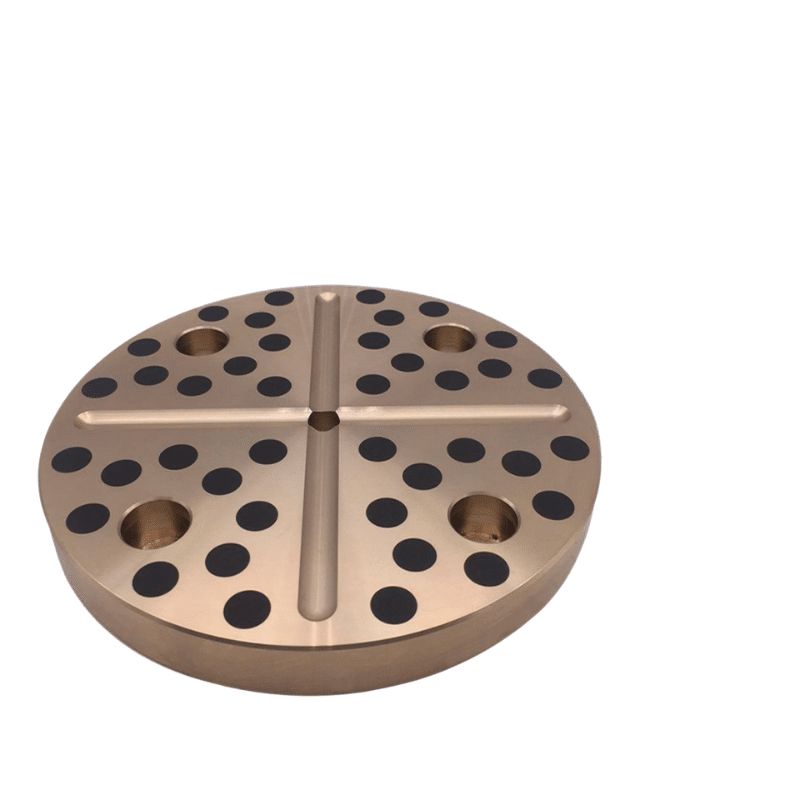

Circular Sizing Plates

Explore Other Alloys, Suggested Searches: Copper Brass Bronze Copper Nickel

Bearing Bushing, Search Our Material Alloy

Circular Sizing Plates, Bronze Wear Plate

Solid Lubricant Embedded Plate

Exploring the Versatility of Circular Sizing Plates: Custom Bronze Graphite Wear Plates

In the world of industrial applications, precision and durability are not just requirements but necessities. One such essential component that embodies these characteristics is the Circular Sizing Plate, especially those enhanced with Bronze Graphite Wear technology. These plates are pivotal in various machinery where sliding motion and wear resistance are critical. Let’s delve into the nuances of these specialized plates and explore their broad range of customizations and applications.

What are Circular Sizing Plates?

Circular Sizing Plates are precisely engineered plates used in machinery for guiding, sizing, and supporting moving parts. They are crucial in applications requiring high precision and minimal wear. The circular design is particularly beneficial for applications that involve rotational or partial rotational movement, making them indispensable in the automotive, aerospace, and manufacturing industries.

The Role of Bronze Graphite in Wear Plates

Bronze Graphite Wear Plates are a step ahead in terms of durability and functionality. Bronze, known for its excellent wear resistance and strength, is further enhanced with graphite. Graphite acts as a solid lubricant, reducing friction and wear even under high load and continuous operation conditions. This combination not only extends the life of the plates but also the machinery they are a part of.

Customization at Its Core

One of the significant advantages of these wear plates is their customizability. Manufacturers can produce Circular Sizing Plates with specific features like grooves, which are essential for certain applications. These grooves can serve various functions such as housing sealing elements, providing pathways for lubricants, or even enhancing the aesthetic appeal of the plate, depending on the application’s requirements.

Customer-Specified Sizes

Every application has unique requirements, and the ability to order Circular Sizing Plates in a broad range of customer-specified sizes is a significant benefit. Whether it’s a small plate for a compact electronic device or a large one for heavy machinery, the precision with which these plates can be sized is paramount. This tailor-made approach ensures that each plate perfectly fits the intended machinery, enhancing performance and reducing the risk for maintenance issues.

Applications of Precision Plates

The applications of Circular Sizing Plates are vast and varied. In the automotive industry, they are used in systems where precise movement is critical, such as in steering mechanisms or gear assemblies. In manufacturing, they are used to guide and position heavy machinery parts. The aerospace sector benefits from these plates in the components of aircraft where reliable and precise movement is crucial for safety and functionality.

The Importance of Choosing the Right Manufacturer

Selecting the right manufacturer for Circular Sizing Plates is crucial. It ensures that the plates not only fit the specific needs of the application but are also made with high-quality materials and craftsmanship. Manufacturers who offer customization options and can provide expert advice on the type of plate and materials suited for different applications are particularly valuable.

Conclusion

Circular Sizing Plates, especially those made from Bronze Graphite, are essential components in industries where precision, reliability, and durability are key. Their customizability in terms of size and features like grooves makes them incredibly versatile and suitable for a wide range of applications. When choosing these precision plates, partnering with a reputable manufacturer who understands the nuances of your specific needs is essential to achieving optimal performance and longevity in your machinery.

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

Solutions For Every Industry

Searching for Dependable Bushing Solutions? viiplus Has What You Need.

Design Guides, Materials

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Technical Guides

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Get Instant Quote

To receive your instant quote, simply upload your drawing file and choose your production process & bushing material.

Prototyping, Place Order

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

Receive Your custom Parts

We provide precision-inspected high-quality parts, packing lists and documents, and delivery tracking.