split bearings

split bearings

Say goodbye to the hassle of frequent lubrication maintenance. Our self-lubricating technology ensures smooth operation and reduces wear and tear, extending the lifespan of your equipment. Experience uninterrupted productivity and cost savings as you bid farewell to the need for messy lubricants and time-consuming upkeep.

Manufacturing on Demand, alternative solutions

split bearings

Sleeve Bearings PTFE lined⚙️

Reliable ptfe lined bearing sleeve bearings built for seamless, low-friction operation in any environment. Exceptional quality, cost-effective solutions.

🛠️ Explore More and get the right bearing for your application!

Sleeve Bearings: The Power of PTFE-Lined Steel Bearings

Split Bearings 🔍

Simplify maintenance with split bearings designed for easy installation and replacement. Reduce downtime and increase efficiency.

🚀 Browse Our Range today and maximize productivity!

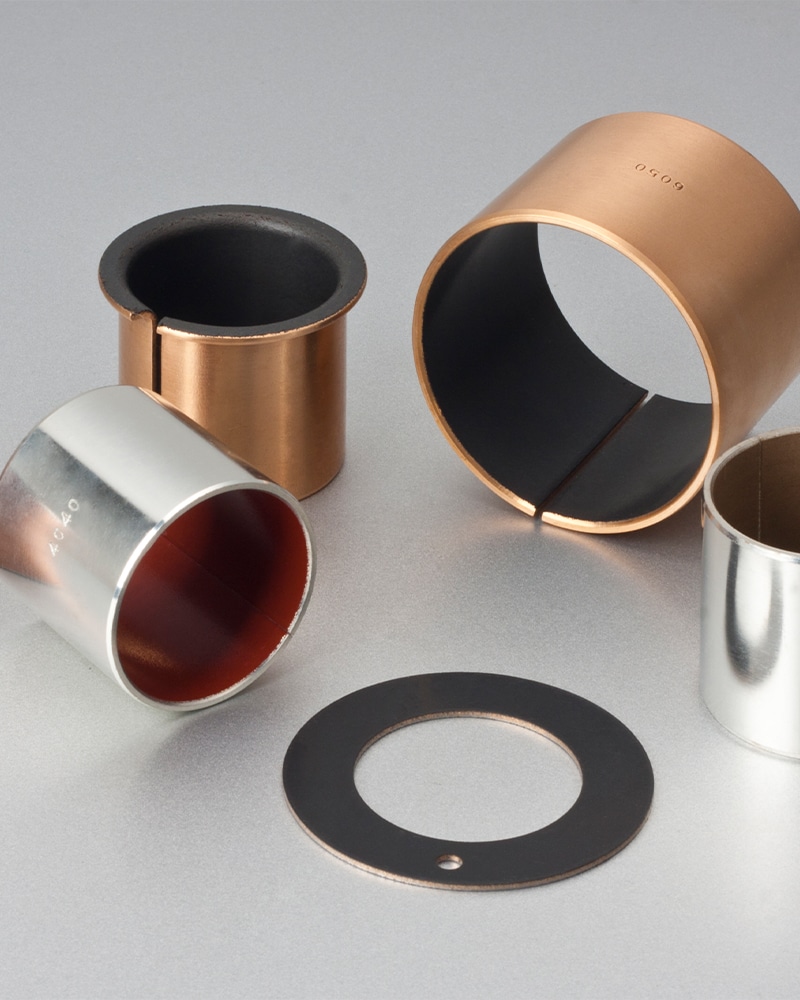

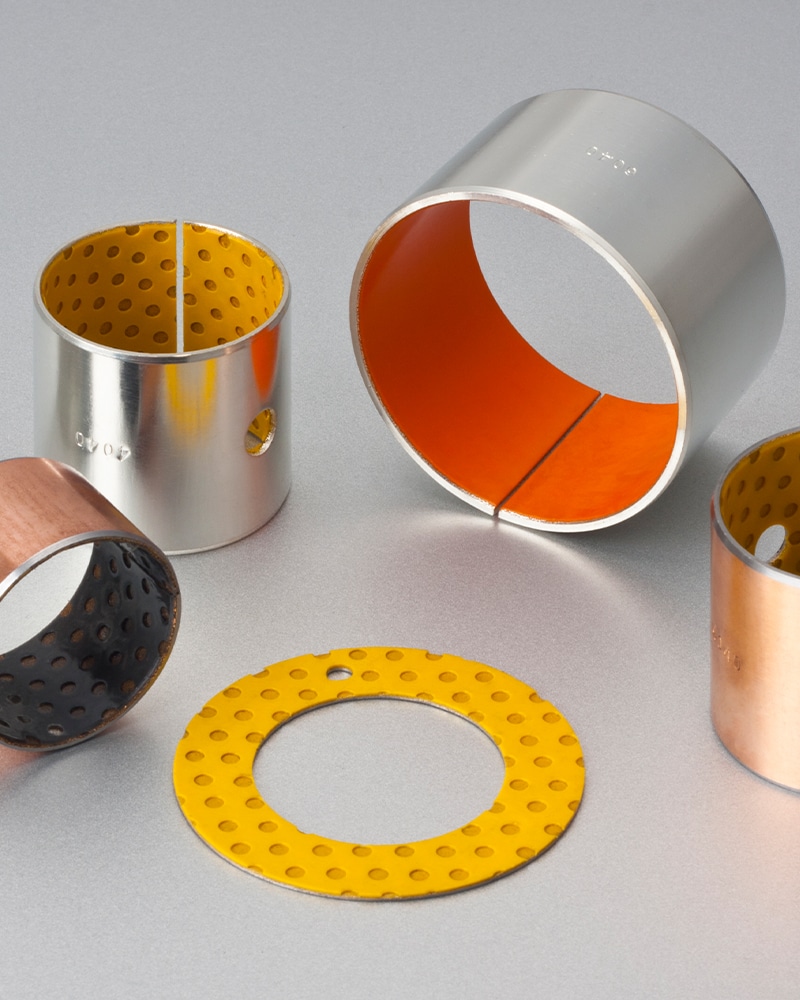

Exploring Sleeve Split Bearings: A Breakdown of PTFE-Lined, Acetal (POM), and Bronze Split Bearings

When it comes to versatile bearing solutions, split bearings are essential for applications requiring efficient installation, low wear, and reliable performance. Split bearings are available in various types to cater to different requirements, and here’s a closer look at PTFE-lined steel bearings, wrapped Acetal (POM) bearings, and bronze bearings.

PTFE-Lined Steel Split Bearings: PTFE-lined steel bearings are engineered for excellent sliding characteristics and durability, making them suitable for dry running and low-wear applications.

Key Features:

- Dry Running Capability: Performs reliably without lubrication.

- Low Wear: Reduced friction extends the lifespan of mating surfaces.

- Corrosion Resistance: The PTFE lining and steel backing resist rust and oxidation.

Applications: Ideal for applications where lubrication is not feasible or where smooth sliding motion is essential, such as automotive suspensions, hydraulic cylinders, and linear guideways.

Discover More:

Learn about the advantages of PTFE-lined steel bearings and how they can optimize your project’s performance.

Wrapped Acetal (POM) Lined Split Bearings

Overview:

Wrapped Acetal (POM) lined split bearings are designed for rotary and oscillating movement, offering low friction and extended re-lubrication intervals.

Key Features:

- Rotary and Oscillating Motion: Handles directional changes smoothly.

- Low Friction: Ensures seamless movement while minimizing wear.

- Re-Lubrication Intervals: Requires less frequent maintenance.

Applications: Ideal for applications like packaging machinery, agricultural equipment, and automotive components where consistent performance is needed.

Bronze Split Bearings

Overview:

Bronze split bearings feature a CuSnB rolled phosphor bronze alloy, providing exceptional durability and reliability for slow-speed, high-load, and oscillating movement.

Key Features:

- High Load Capacity: Handles significant loads due to the inherent strength of bronze.

- Oscillating Applications: Designed to deliver consistent performance with directional changes.

- Corrosion Resistant: Bronze alloy resists oxidation and wear.

Applications: Perfect for demanding environments in construction machinery, earthmoving equipment, and marine applications where high loads and slow speeds are common.

Conclusion

Whether you require PTFE-lined, Acetal (POM) lined, or bronze bearings, split bearing technology offers tailored solutions for various industrial needs. Each type of bearing provides unique advantages in performance, durability, and maintenance. Contact us today to explore the best split bearing solution for your specific requirements, ensuring optimal performance and efficiency for your next project.

Plain Lined Bearings: Exploring Advanced Bearing Technologies

Plain Lined Bearings: Exploring Advanced Bearing Technologies

Bearing technology has evolved significantly over time, offering innovative solutions that cater to a variety of applications. Among these, plain lined bearings stand out due to their simplicity, versatility, and reliability. Let’s take a closer look at plain lined bearings and how they have transformed bearing technology.

What Are Plain Lined Bearings?

Plain lined bearings, often referred to as sleeve bearings or bushings, are a type of bearing where one surface slides over another with minimal friction. They consist of a metal or composite outer shell and a specially formulated lining that acts as a low-friction, wear-resistant surface.

Advanced Features of Plain Lined Bearings

- Self-Lubricating

Many modern plain lined bearings feature self-lubricating liners made of materials like PTFE, Acetal (POM), or composite blends. These liners eliminate the need for frequent maintenance and provide long-lasting performance. - High Load Capacity

With metal or high-strength composite backing, these bearings can handle substantial loads, making them suitable for demanding applications in various industries. - Corrosion Resistance

Linings can be engineered to withstand moisture, chemicals, and extreme temperatures, ensuring reliable operation even in harsh environments. - Dimensional Stability

Advanced materials offer excellent dimensional stability, providing consistent performance under varying mechanical and thermal conditions. - Easy Installation

Their simple design allows for straightforward installation, reducing downtime and improving efficiency in manufacturing and maintenance processes.

Applications of Plain Lined Bearings

Plain lined bearings are widely used across multiple industries due to their versatility and reliability. Key application areas include:

- Automotive Industry: Used in engines, transmissions, and suspension components.

- Agricultural Machinery: Handles high loads and resists corrosion in tough environments.

- Construction Equipment: Ensures reliable performance in machinery exposed to dust, dirt, and heavy loads.

- Aerospace Industry: Provides low-friction movement in critical aircraft components.

- Marine Applications: Resists corrosion in seawater and supports smooth operation.

Innovations in Bearing Technology

The development of new lining materials, such as PTFE and composite blends, has significantly improved the performance of plain lined bearings. These advancements offer:

- Reduced Friction: Advanced materials ensure smooth operation with minimal wear on mating surfaces.

- Extended Lifespan: Improved linings increase the bearing’s longevity, even under challenging conditions.

- Customization: Bearings can be tailored to meet specific application needs, from temperature resistance to unique load capacities.

Conclusion

Plain lined bearings continue to play a vital role in modern bearing technology. Their simplicity, combined with advanced materials and engineering, ensures that they provide reliable performance in a wide range of applications. If you’re looking for a bearing solution that is durable, low-maintenance, and versatile, plain lined bearings could be the ideal choice. Contact us to learn more about our range and how we can help meet your specific bearing requirements.

Your expert in self-lubricating Bearing

and Bronze alloys – serving globally

Brand replacement products and functionally equivalent parts, alternative solutions

Manufactures flange bronze bearings, service & maintenance companies to meet the exacting specifications required in a wide range of industrial applications.

Machined bronze bushing that meet the exacting requirements & specifications supplied by our clients. Spherical bearings, spindles, semi-spheres and supports that we have manufactured.

You will find to follow a selection of self lubricating bronze bearing material CuSn7Zn4Pb7, CuSn12, CuAl10Fe5Ni5,

CuZn25Al5Mn4Fe3

Alternative solution,We offer an outsourced machining service for bronze bushes, manufacturing precise parts to the designs supplied to us by our clients.

Selection of other composite bushing material of self lubricating bearing that we have manufactured.

Wrapped Bronze Sleeve Bearing, Are you interested in our products?

Manufacturer of bimetal and steel bronze bushing parts according to client’s drawing.