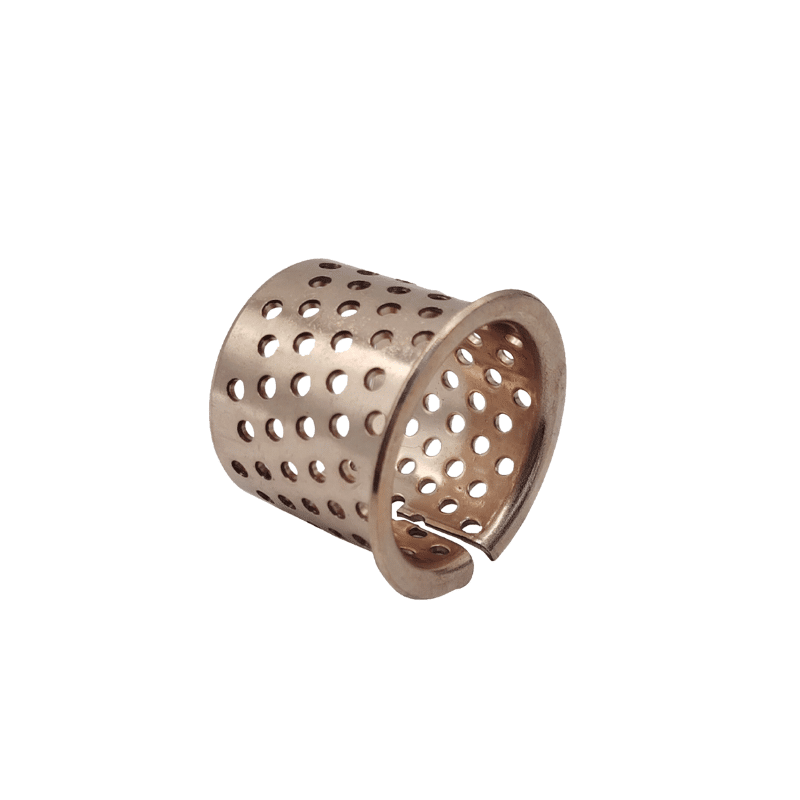

Continuous Casting Bronze, Continuous Casting for Bronze Bushings, Continuous Cast Bronze Sleeve

Experience the Strength of Self-lubricating Bearings

High-Quality Bronze Bushings,Material Selection:

Choose the appropriate bronze alloy based on the bushing’s intended application. Leaded bronze or aluminum bronze might be selected for their enhanced wear resistance and corrosion properties. Continuous casting provides a versatile and efficient method for producing custom bronze bushings tailored to the specific needs of various industries. Bronze Bushing Supplier,Quality You Can Trust! Specializing in continuous casting for robust and precise bronze bushings. Reduce downtime and increase efficiency. Request your sample today!

Providing Brass, Bronze, and Specialty Copper Alloys, Copper Alloy Machining Services

Benefits of Continuous Casting for Bronze Bushings:

Continuous Cast Alloys · C86300 (SAE 430B) Manganese Bronze Bushing · C86300 (SAE 430B) Manganese Bronze Bearings.

Continuous casting is a process that can be used to produce bronze bearing bushings with a high degree of precision and consistency.

- Consistency: The continuous casting process ensures a high degree of uniformity in the microstructure and properties of the bronze bushings.

- Efficiency: This method is highly automated and can produce bushings at a faster rate compared to traditional casting methods, reducing production time and costs.

- Precision: The controlled cooling and solidification in continuous casting allow for the production of bushings with precise dimensions and tolerances.

- Material Utilization: There is less material waste in continuous casting, recognized to a more cost-effective and environmentally friendly process.

Continuous Casting Process Overview

Continuous casting is a modern method widely used for producing metals in continuous lengths, such as billets, blooms, slabs, and sheets. This process is significantly more efficient than traditional ingot casting and offers numerous advantages:

- Melting: Bronze or its alloys are melted in a furnace at high temperatures.

- Tundish: The molten metal is transferred to a tundish, a type of holding furnace, which ensures even distribution of the metal to the molds.

- Casting Mold: The metal flows into a water-cooled, vertical, open-ended mold where it begins to solidify upon contact with the mold walls.

- Withdrawal: The partially solidified metal is steadily drawn from the bottom of the mold, synchronized with the rate of solidification to maintain continuous casting.

- Secondary Cooling: The emerging billet or strand undergoes further cooling via water sprays or air blasts in a secondary cooling zone to complete solidification.

- Sizing and Cutting: Once fully solidified, the metal is cut to desired lengths, and ends are trimmed to eliminate defects.

- Quality Control: The final product is inspected and tested for quality assurance, checking dimensions, surface finish, and internal integrity.

Applications of Bronze and Its Alloys in Continuous Casting:

- Leaded Bronze: Ideal for harsh environments, used in bearings and gears due to its excellent resistance to corrosion and abrasion.

- Aluminum Bronze: Utilized in marine hardware, pumps, and valves, known for its high strength, hardness, and corrosion resistance.

- Brass: Chosen for acoustic properties, electrical conductivity, and corrosion resistance, used in technology and various metal goods.

- Aluminum/Phosphor Bronze: High-performance materials for extreme mechanical and chemical stress, suitable for aerospace and automotive industries.

Metallurgical Engineering Services & Quality Assurance:

- Chemical Analysis: Ensures the alloy composition meets specific requirements.

- Metallurgical Analysis: Assesses microstructure to evaluate grain size, phase distribution, and inclusions.

- Non-Destructive Testing (NDT): Includes ultrasonic, radiographic, and dye penetrant testing to check integrity without damage.

- Mechanical Testing: Determines mechanical properties like tensile strength, yield strength, and elongation.

- Surface Analysis: Checks for surface defects such as cracks, pits, or inclusions.

Copper and Its Alloys: Often called “red gold,” copper is highly valued for its superior electrical and thermal conductivity. It’s extensively used in electrical wiring, plumbing, and construction, prized for its durability, corrosion resistance, and workability.

Continuous casting of copper and its alloys ensures the production of high-quality, consistent materials crucial for various industrial applications, offering an efficient and environmentally friendly alternative to traditional methods.

Applications of Continuously Cast Bronze Bushings:

- Automotive Industry: In applications such as wheel bearings, gearboxes, and suspension components.

- Marine Applications: For propeller shaft bearings and other components exposed to saltwater.

- Industrial Machinery: In plain bearings, thrust bearings, and bushings for pumps, compressors, and conveyor systems.

- Renewable Energy: In wind turbines and tidal generators where reliable, low-maintenance bearings are required.

4o