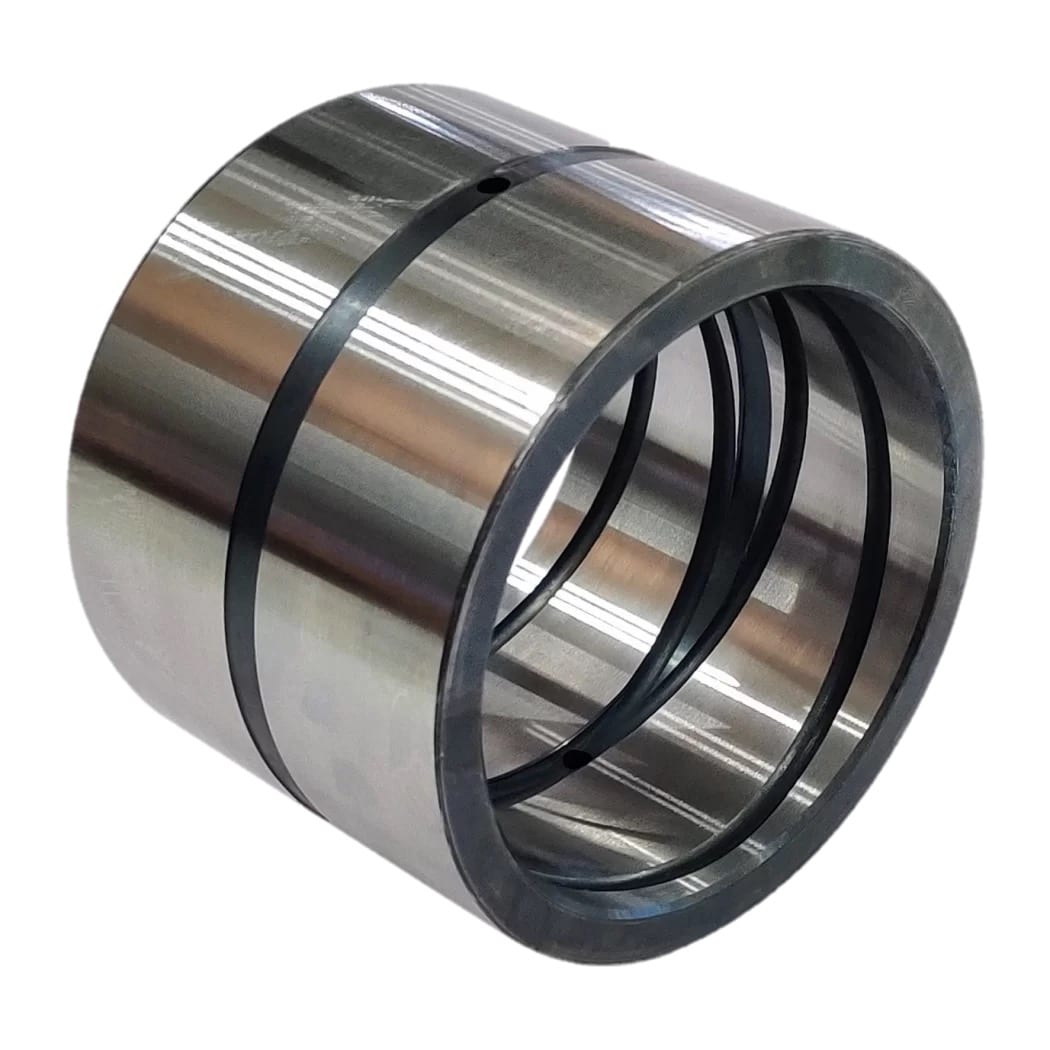

High Carbon Steel Bushing Made of 42CrMo4 Bearing Bushing, Carbon steel for machine structure alloy steel [C45, 42CrMo4)

About us

Custom-Made Steel 42CrMo4/ c45 Bearing Bushing

The 42CrMo4 bearing bushing, crafted from high-strength, low-alloy steel, is designed for demanding industrial applications that require superior strength, toughness, and wear resistance. This steel bearing is ideal for conditions involving heavy loads, high temperatures, and corrosive environments. Notably recognized for its mechanical robustness, the 42CrMo4 steel can be hardened and tempered to attain significant surface hardness, enhancing its resistance to wear and corrosion.

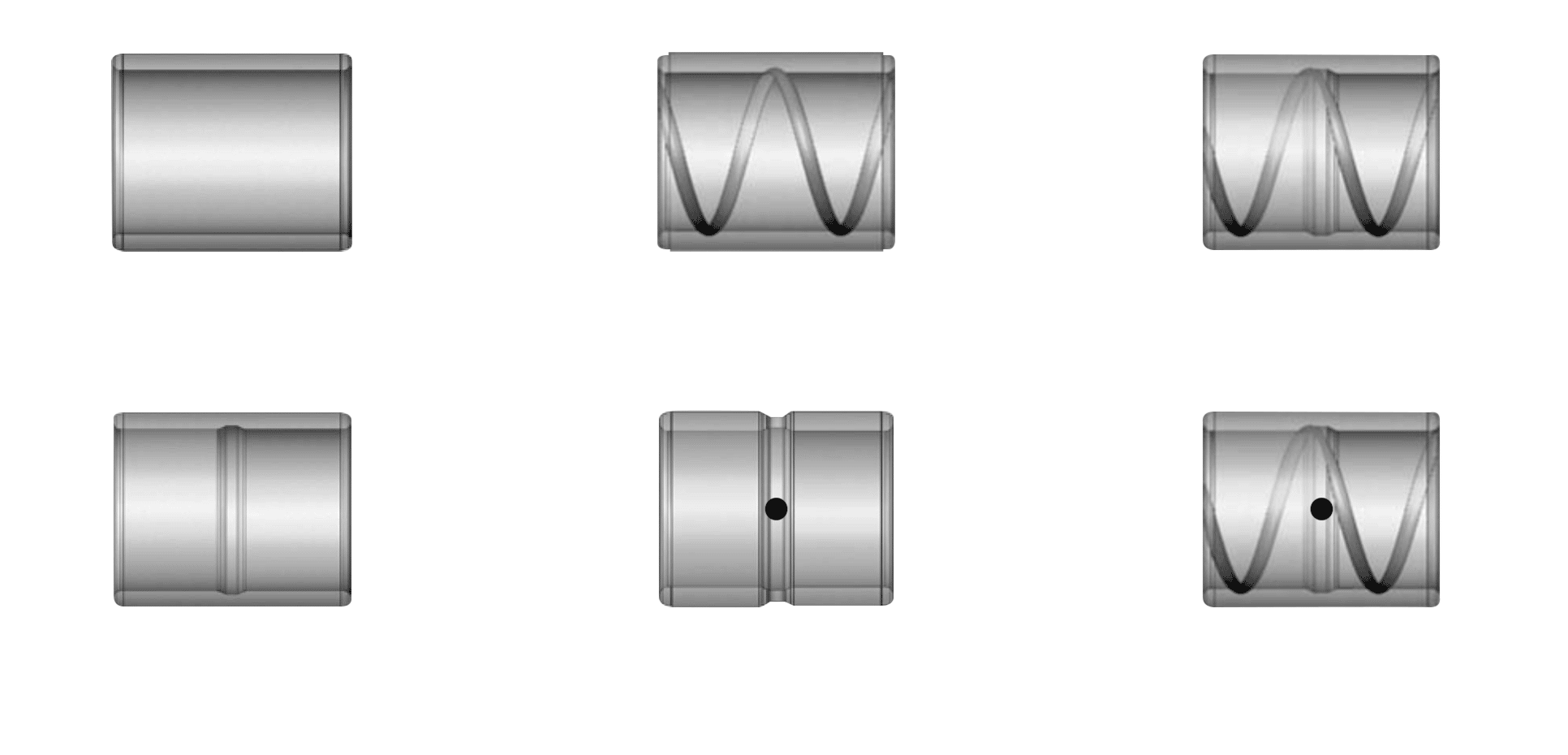

Type Of Bearing

Understanding the 42CrMo4 Alloy Steel Bushings: Groove Types and Their Applications

Available in multiple sizes and configurations, the 42CrMo4 bearing bushing can be tailored to specific application needs, including custom dimensions, material types, and desired levels of hardness and wear resistance. This versatility makes it suitable for a wide array of uses across various sectors, such as machinery manufacturing, construction of buildings and bridges, and production of vehicles and other transportation equipment.

42CrMo4 alloy steel, known for its robust strength and wear resistance, is a popular choice for bushings in mechanical systems. A critical feature in the design of these bushings is the inclusion of grooves, which play a vital role in lubrication and functionality. CHARACTERISTICS

- Steel bushings are ideally suited for lubricated applications.

- Available with either a plain or grooved sliding layer.

- Specifically designed for grease lubrication.

- Optimal for low rotation speed environments with high specific pressure.

Heavy-duty steel bushings featuring round oil pockets and oil ring grooves, made from AISI-4140 / AISI-4142, DIN 42CrMo4 hardened steel.

Renowned for its high quality and performance, the 42CrMo4 bearing bushing ensures durable and reliable service in numerous applications. Its popularity among manufacturers and engineers is owed to its exceptional mechanical properties and its capability to withstand tough operational conditions. In essence, the 42CrMo4 bearing bushing is a robust, low-alloy steel plain bearing, customizable and adaptable for diverse industrial uses where durability and resistance are paramount.

AVAILABILITY: Bearing forms are available in standard dimensions:

- Plain cylindrical bushes

- Custom-made bearing forms are also available:

- Bearings with various lubrication grooves

- Non-standard parts tailored to specific requirements

DIN 42CrMo4 Bushing Material Features:

Steel bushings and bearings are perfectly designed for your applications that require grease and oil lubrication. They are available with either a plain or grooved sliding layer to suit various operational needs.

Material Features:

- Hardened steel bearings offer enhanced wear resistance, while the core remains ductile and crack-resistant.

- Suitable for heavy machinery, hydraulic cushioning, and rotational applications.

- The special alloy, enriched with manganese and vanadium, provides improved strength and toughness, accelerated hardening, and superior wear resistance.

Design Custom Aluminium bronzes Parts & International Standards: Search Our Material Alloy

Design Custom Parts & High Carbon Steel Bushing for Excavators, made from 42CrMo4/40Cr steel.

Plain bearings, Hardened steel bushings are reinforced with a steel backing and feature an inner surface designed with a variety of lubrication-enhancing elements, including spiral oil grooves, oil rings, oil holes, as well as round and elliptical oil sockets. These bushings undergo quenching and tempering processes that enhance their surface roughness and wear resistance.

This product is primarily used in the engineering machinery sector and in applications requiring high wear resistance, with the capability to withstand heavy loads without cracking. In the design of certain mechanical parts (such as bearings), to improve lubrication, internal features like circular oil grooves and oil ring grooves are incorporated. These designs help maintain the flow of lubricating oil, reduce friction and wear, and extend the lifespan of the parts.

Here, we explore the different types of grooves used in 42CrMo4 alloy steel bushings and their specific applications.

1. Straight Grooves

Straight grooves are commonly used in bushings and are characterized by their linear pattern. These grooves are typically machined parallel to the axis of the bushing. They are designed to distribute lubricant evenly along the length of the bushing, ensuring consistent lubrication and reducing wear between the bushing and the mating component. This type of groove is ideal for applications where relative linear motion occurs, such as in hydraulic cylinders and linear actuators.

2. Spiral Grooves

Spiral grooves in bushings are designed to facilitate not only lubrication but also the removal of debris and contaminants from the bearing surface. These grooves create a helical path for lubricants, enhancing the distribution across the bushing during rotational movements. This design is particularly beneficial in rotary applications, such as in electric motors and rotating shafts, where it helps maintain a film of lubricant under dynamic load conditions.

3. Circular Grooves

Circular grooves, also known as annular grooves, are typically used in applications involving oscillating movements. These grooves are machined around the circumference of the bushing and help retain lubricant within the designated area. Circular grooves are effective in applications such as pivot joints and linkages, where the range of motion does not involve complete rotation or extensive linear travel.

4. Figure-Eight or Double Loop Grooves

These are specialized grooves that resemble the figure-eight shape and are used in applications requiring multi-directional lubrication paths. These grooves ensure that lubrication is supplied effectively to both rotational and axial movements, making them suitable for complex mechanical systems where the bushing experiences varied motion patterns.

Applications and Industries

Bushings with these various groove types are employed in a broad range of industries:

- Automotive: Used in suspension joints, steering systems, and transmission assemblies.

- Aerospace: Components in control mechanisms and landing gear.

- Industrial Machinery: In hydraulic systems, rotating shafts, and moving arms where high load and high wear resistance are critical.

Conclusion

Choosing the right groove type for 42CrMo4 alloy steel bushings is essential for optimizing the performance and longevity of mechanical assemblies. Each groove type offers distinct benefits tailored to specific mechanical movements and operational conditions. Understanding these variations helps engineers and designers select the most appropriate bushing configuration, ensuring efficient and reliable operation of machinery across various industrial applications.

42CrMo4 bearing bushings are known for their superior mechanical properties, which include high strength, good toughness, and excellent wear resistance. These characteristics make them suitable for a wide range of applications where reliability and durability are crucial. Here are some typical applications for 42CrMo4 bearing bushings, as mentioned in your query:

- Earth Movement Machinery: In heavy equipment such as excavators and loaders, bearing bushings need to withstand substantial loads and abrasive conditions. The strength and wear resistance of 42CrMo4 make it an ideal choice for these applications.

- Drilling Machinery: Drilling equipment often operates in harsh environments and requires components that can handle high stress and resist wear. 42CrMo4’s properties make it suitable for use in such machinery.

- Farming Machinery: Components like power harrows, ploughs, and rear excavators in agricultural machinery experience significant wear and tear. The durability of 42CrMo4 bearing bushings contributes to the longevity of these machines.

- Equipment Attachments: Tools such as grabs, buckets, and grippers used in various heavy-duty applications can benefit from the strength and wear resistance of 42CrMo4 bearing bushings.

- Hydraulic Cylinders: To protect against wear, especially at the bottoms and eyelets of hydraulic cylinders, 42CrMo4 bushings are used to enhance service life and reliability.

- Industrial Washing Machines: As consumables in these machines, 42CrMo4 bushings can withstand the rigors of frequent use and the corrosive nature of detergents and water.

- Sliding Guides for Industrial Presses: The precision and durability required in industrial presses mean that components like sliding guides need to be made from high-quality materials. 42CrMo4 provides the necessary strength and wear resistance.

- Components for Suction Pumps: For sliding seats in pumps and sealing rings, the material must be able to operate smoothly under pressure. 42CrMo4’s properties make it a good fit for these components.

- Machine Tools and Automatic Machines: In precision machinery, the components must be able to maintain accuracy over time. 42CrMo4’s wear resistance and strength contribute to the longevity and reliability of machine tools and automatic machines.

- Pumps and Industrial Presses: These applications require components that can handle high pressure and resist wear. The use of 42CrMo4 bearing bushings can enhance the performance and lifespan of pumps and presses.

The 42CrMo4 steel’s combination of strength, toughness, and wear resistance makes it a versatile material for a variety of bearing bushing applications where performance under load and durability are key considerations.